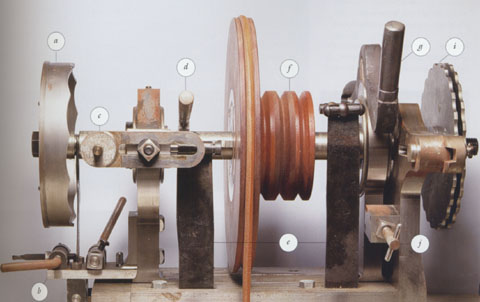

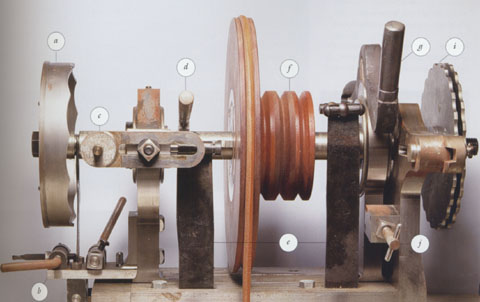

Figure 35 Side view of the Carpentier engine lathe showing the basic working components. (a) The crown (end) cam: left and right edges can be cut with patterns. (b) Double-action, crown-cam spring assembly: allows crown cam to be followed on left or right edge and creates spring tension for the sideways pumping action. Josiah Wedgwood describes making this addition to his redesigned lathe in a 1768 letter. (c) Crown-cam follower. (d) Lock to keep main shaft from moving sideways. (e) Main springs: put pressure against pivoting main frame as it follows the edge cams and produces a rocking motion. (f) Wooden pulleys: using a large pulley slows the motion and using a small pulley increases it. (g) Mainframe locking arm (seen in the down position): prevents the front-to-rear rocking action. (h) Spring tensioner: increases pressure on main springs, either forward or backward. (i) Edge cams: can be changed simply by removing a nut and sliding another cam on or off. Like the double-action, crown-cam spring assembly, this appears to have been invented by Wedgwood for use on his 1768 redesigned lathe. (j) Depth stop: controls the depth of cut the knives make in the body. (All demonstration photos by Gavin Ashworth.)

|