Sideboard table with carving attributed to the shop of James Reynolds, Philadelphia, Pennsylvania, 1766–1776. Mahogany with yellow pine and walnut; clouded limestone. H. 33 1/4", W. 33", D. 21 1/2". (Courtesy, Winterthur Museum.)

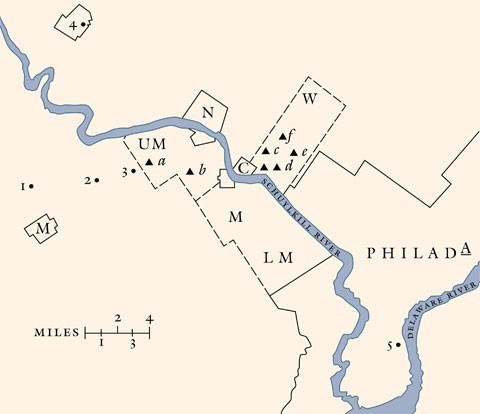

Map of the Philadelphia region showing quarries, churchyards, and towns.

Quarries: (a) Henderson, (b) Brooks/Reeseville, (c) Wilkinson/Fritz/Potts, (d) Traquair/Cedar Grove, (e) Marble Hall, (f) Lentz. Churchyards: (1) Saint Peter’s, (2) Great Valley Presbyterian, (3) Great Valley Baptist, (4) Trappe Lutheran, (5) Gloria Dei. Towns: (C) Conshohocken, (M) Malvern, (N) Norristown, (W) Whitemarsh.

Samples of European marble owned by James Logan (1674–1751). (Courtesy, Fairmont Park Commission.) Logan probably received these samples from colleagues in London. Similar marble appears on furniture used in Philadelphia during the eighteenth century.

Lime kilns on Germantown Avenue in Plymouth Township, Pennsylvania. (Photo, Gavin Ashworth.) Plymouth Township is approximately twenty miles northwest of Philadelphia. These kilns were loaded from the top with limestone blocks then burned for days.

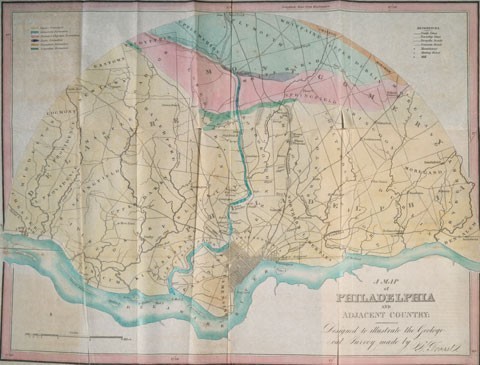

Detail of a geological map of Philadelphia illustrated on page 10 of Dr. Gerhard Troost’s Geological Survey of the Environs of Philadelphia performed by the order of the Philadelphia Society for promoting Agriculture (Philadelphia: H. S. Tanner, 1826). (Courtesy, The Academy of Natural Sciences, Ewell Sale Stewart Library.)

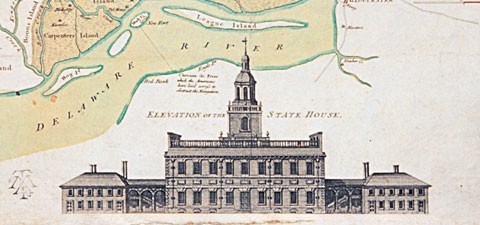

Elevation of the Pennsylvania State House shown on Matther A. Lotter, A PLAN of the City and Environs of PHILADELPHIA, Pennsylvania, 1777. This image shows the north façade which has figured limestone panels between the first and second floor windows and soapstone quoins. (Courtesy, Winterthur Museum.)

Detail showing a panel and a keystone on the Pennsylvania State House. This fielded panel is one of nine placed between the first and second floor windows of the north façade.

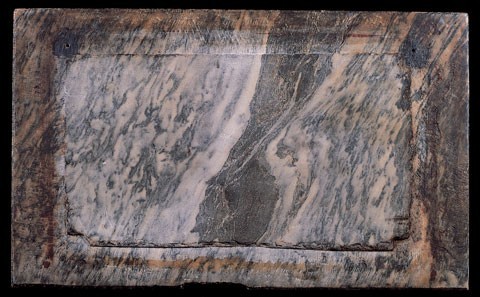

Sample of clouded limestone collected during the first or second geological survey of Pennsylvania at C. Earnest’s quarry between Norristown and Philadelphia. (Courtesy, State Museum of Pennsylvania; photo, Gavin Ashworth.)

Sample of clouded limestone collected during the first or second geological survey of Pennsylvania at a quarry near Upper Merion Township. (Courtesy, State Museum of Pennsylvania; photo, Gavin Ashworth.) The brown diagonal line across the top of the sample is iron, and the large blue areas are deposits of magnesium within the matrix of calcium carbonate.

Tombstone for David James, Great Valley Baptist Church, Upper Merion Township, Pennsylvania, dated 1730. (Photo, R. Curt Chinnici.) This is one of the earliest Pennsylvania tombstones made of clouded limestone.

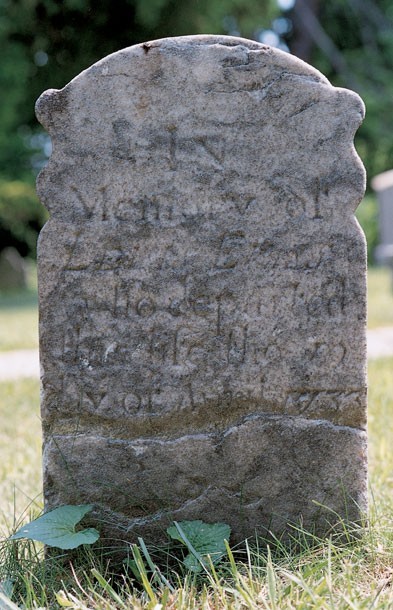

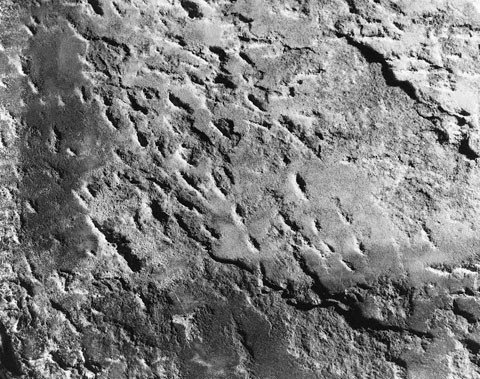

Tombstone with an eroded inscription, Great Valley Baptist Church, Upper Merion Township, Pennsylvania, dated 1733. (Photo, Gavin Ashworth.)

Detail showing the back of the tombstone illustrated in fig. 11.

Tombstone for James David, Saint Peter’s Church, Chester County, Pennsylvania, dated July 24, 1746. (Photo, Gavin Ashworth.)

Detail of the back of a tombstone for P. Lloyd, Great Valley Presbyterian Church, Chester County, Pennsylvania, dated April 1802. (Photo, Gavin Ashworth.)

Detail showing the saw kerfs on the back of a tombstone for Major Ezekiel Howell, Great Valley Presbyterian Church, Chester County, Pennsylvania, dated October 4, 1812. (Photo, Gavin Ashworth.)

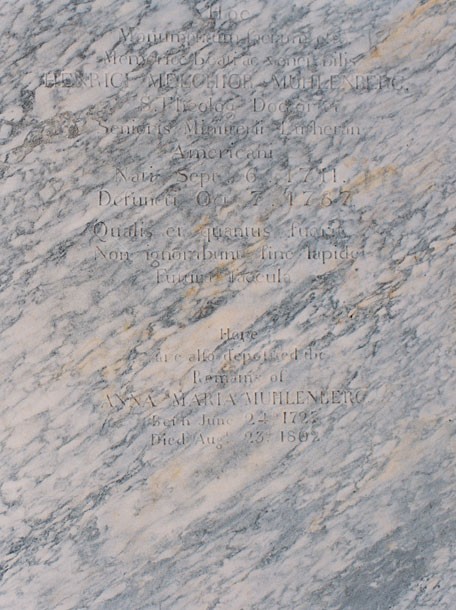

Altar tomb for Henry and Anna Marie Muhlenberg, Augustus Lutheran Church, Trappe, Pennsylvania, dated October 7, 1787, and August 23, 1802. The stone for the tomb was probably cut in 1787. (Photo, Gavin Ashworth.)

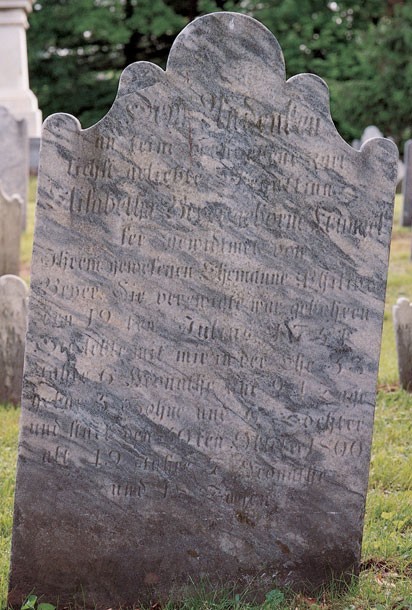

Tombstone with old German script, Augustus Lutheran Church, Trappe, Pennsylvania, dated 1751. (Photo, Gavin Ashworth.)

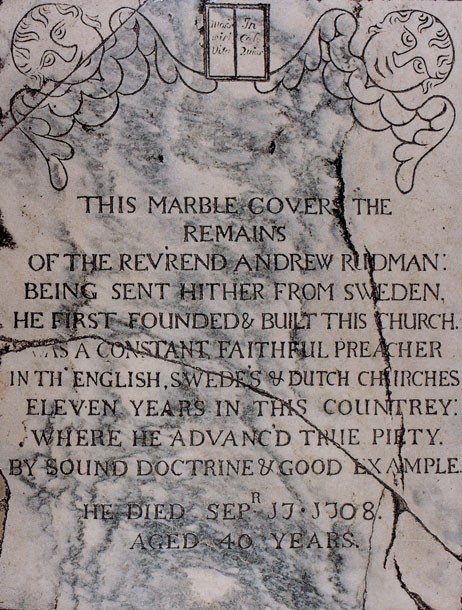

Grave marker for Rev. Andrew Ridman, Old Swedes Episcopal Church, Philadelphia, Pennsylvania, dated 1708. (Photo, Gavin Ashworth.)

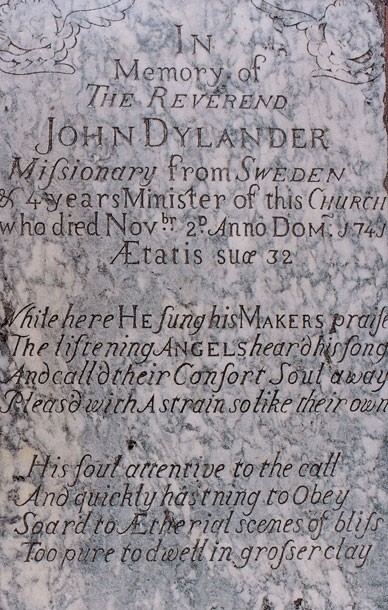

Grave marker for Rev. John Dylander, Old Swedes Episcopal Church, Philadelphia, Pennsylvania, dated 1741. (Photo, Gavin Ashworth.)

Baptismal bowl, Old Swedes Episcopal Church, Philadelphia, Pennsylvania, eighteenth century. (Photo, Gavin Ashworth.)

Detail of the back of the tombstone illustrated in figs. 11, 12.

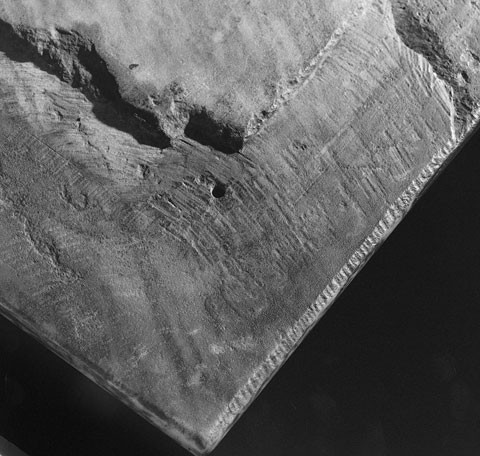

Detail of the underside of the top of the sideboard table illustrated in fig. 30.

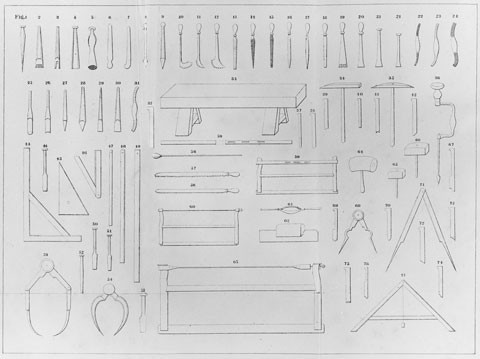

Illustration showing stone cutters’ tools illustrated in The Marble Worker’s Manual. No. 1 — square etching needle; nos. 2, 4, 19, 20, 64 — marteline chisels used for etching and with a mallet or sledge hammer, no. 5 — puncheons; nos. 8, 9, 27, 28 — partly flattened, very sharp etching needles called houguettes; no. 10 — hooks for sinking and leveling cavities; no. 11 — round-nosed chisels for sinking and leveling cavities; no. 12 — sharp edged and notched scrapers for fluting; no. 19 — scrapers for fluting; no. 31 — parting tools bent round and steeled at each end to smooth areas difficult to reach; no. 34 — martelines (iron mallets pointed at one end, and diamond shaped at the other) used to pierce and shell off the marble without splintering; no. 61 — sebillas, or wooden bowls for holding the sand and water that would be thrown under the saw; no. 56 — wooden or metal ladles used with the sebillas; no. 62 — handsaws without teeth, used to cut stone or marble with the aid of sand or water. "A skillful workman often confines himself to making a deep groove in the Marble or stone, and then by a quick blow, separates the two pieces." (Courtesy, Winterthur Museum Library: Printed Book and Periodical Collection.)

Details showing (from top to bottom): an etching needle and mallet being used to chip away small pieces of stone, a flat marteline chisel being used to level the surface, and a chisel and mallet being used to table the edges of a slab. (Photo, R. Curt Chinnici.) The marteline chisel performs the same function as an etching needle, but it leaves parallel tooth marks.

Sideboard table with carving attributed to the shop of Samuel Harding, Philadelphia, Pennsylvania, 1740–1755. Mahogany with yellow pine and white cedar; Italian marble. H. 29", W. 42", D. 22". (Courtesy, Diplomatic Reception Rooms, U. S. Department of State; photo, Will Brown.) The top appears to be the third one used on this frame. Screw pockets on the inner faces of the rails indicate that the table had a wooden top at one point, but its original was probably clouded limestone or marble.

Sideboard table, Philadelphia, Pennsylvania, 1735–1745. Mahogany with tulip poplar; clouded limestone. H. 30", W. 44 3/4", D. 21 1/2". (Courtesy, Baltimore Museum of Art, bequest of J. Gilman D’Arcy Paul; photo, Gavin Ashworth.)

Detail of the edge molding on the top of the sideboard table illustrated in fig. 26.

Detail of the underside of the top of the sideboard table illustrated in fig. 26.

Detail of the saw kerfs on the back edge of the top of the sideboard table illustrated in fig. 26.

Sideboard table attributed to the shop of Henry Cliffton and Thomas Carteret, Philadelphia, Pennsylvania, ca. 1755. Mahogany; clouded limestone. H. 29 1/4", W. 36 1/2", D. 22 1/4". (Private collection; photo, Gavin Ashworth.)

Top of the sideboard table illustrated in fig. 30.

Detail of the underside of the top of the sideboard table illustrated in fig. 30, showing a hole for a metal indexing pin.

Sideboard table with carving attributed to the shop of Nicholas Bernard and Martin Jugiez, Philadelphia, Pennsylvania, 1760–1770. Mahogany with yellow poplar; clouded limestone. H. 29 7/8", W. 42 5/8", D. 21". (Courtesy, Museum of Fine Arts, Boston; M. and M. Karolik Collection.)

Detail of a chimneypiece and fireplace surround in Graeme Park, Montgomery County, Pennsylvania, 1750–1760. (Courtesy, Winterthur Museum Library: Printed Book and Periodical Collection.) This is the earliest fireplace surround made of highly variegated Pennsylvania limestone in its original location. The horizontal stone is 64" wide and 9 7/8" high. The two supporting side panels are 44" high and 7" wide. The inner edge of the stone has a 3/8" bead on three sides. The bead stops 10" from the floor, which is the same height as the baseboard. On the left panel, a horizontal, scored line indicates the baseboard level. The hearth stones are original, but they have been reset. Similar tiles and limestone surrounds are in later Philadelphia residences including the Physick House.

Detail of a chimneypiece and fireplace surround in Andalusia, Bucks County, Pennsylvania, 1833–1835. (Courtesy, Andalusia Foundation; photo, Gavin Ashworth.)

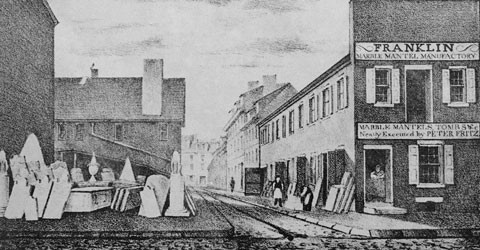

View of Race Street between 6th & 7th, Philadelphia, 1834. (Photo, R. Curt Chinnici.) This image from a newspaper fragment shows the Franklin Marble Mantel Manufactory and funeral statuary owned by Peter Fritz.

Girard College, designed by Thomas Ustick Walter (1804–1887), Philadelphia, Pennsylvania, 1833–1847.(Courtesy, Girard College; photo, Gavin Ashworth.)

Merchant’s Exchange Building, designed by William Strickland (1788– 1854), South Third and Walnut Streets, Philadelphia, Pennsylvania, 1832–1834. (Photo, Gavin Ashworth.)

Second Bank of the United States, designed by William Strickland, Chestnut Street, Philadelphia, Pennsylvania, 1818. (Photo, Gavin Ashworth.)

Pier table, Philadelphia, Pennsylvania, 1820–1830. Mahogany and mahogany veneer with pine; imported white Italian marble. H. 43 15/16", W. 50 1/8", D. 23 15/16". (Courtesy, Winterthur Museum.)

Corner table, Baltimore, Maryland, 1795–1805. Mahogany and satinwood with white pine; clouded limestone. H. 37", W. 27 1/2", D. 20 7/8". (Courtesy, Winterthur Museum.)

Center table, Philadelphia, Pennsylvania, 1825–1835. Maple and maple veneer with white pine; clouded limestone. H. 27", Diam. of top: 43 5/8". (Courtesy, Andalusia Foundation; photo, Gavin Ashworth.) This table is part of the furniture brought to Andalusia by Nicholas Biddle when he moved from Philadelphia to this country house on a permanent basis.

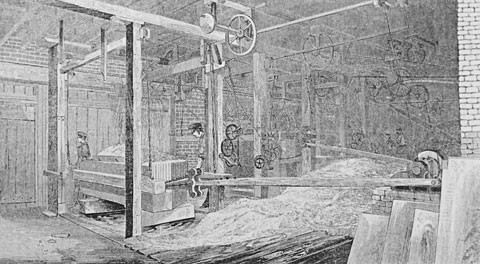

Illustration titled the “Sawing-Rooms of J. & M. Baird’s Steam Marble Works,” from Godey’s Lady’s Book (1853). (Photo, R. Curt Chinnici.)

Washstand, Philadelphia, Pennsylvania, 1830–1845. Mahogany veneer on white pine; clouded limestone. H. 28", W. 28", D. 22 3/4". (Private collection; photo, Gavin Ashworth.) Unlike most nineteenth-century slabs, the top on this stand is rough on the underside and tabled to fit the frame. The tableing actually impedes a towel bar that pulls out on one side. A similar washstand with three drawers has a stenciled label of Anthony Quervelle.

This province yields many kinds of marble, especially a white one with pale-gray, bluish spots, that is found in a quarry at the distance of a few miles from Philadelphia. They make many tombstones and tables, enclose chimneys and doors, floors of marble flags in the rooms, and the like of this kind of marble. A quantity of this commodity is shipped to different parts of America.

—Peter Kalm, September 20, 1748

Various stones quarried in the environs of Philadelphia—limestones, sandstones, and schists—have contributed significantly to the architecture and decorative arts of that city. This has led to much speculation regarding the source and geological composition of these stones, particularly those referred to generically as “marbles.” The color and figure of limestone from southeastern Pennsylvania is varied, ranging from pure white to variegated blue and white to dark blue. Much of it was used for mantles and other architectural details, but some of the most beautiful and interesting examples of this stone are on furniture (fig. 1). An analysis of the stone industry in Philadelphia and market distinctions made by eighteenth- and nineteenth-century craftsmen illuminates the uses and limitations of what is now known as “King of Prussia marble.”[1]

Limestone from the Philadelphia Region

The pseudo-marble from southeastern Pennsylvania has garnered many names based on its supposed origin. “King of Prussia marble,” “Conshohocken blue,” and “Schuylkill gray” all derive from locations of quarries within the limestone belt crossing three counties that surround the city of Philadelphia. This extensive limestone deposit begins in Montgomery County, which is just north of the city, and crosses the Schuylkill River to the southwest extending through Chester and Lancaster counties. The length of the limestone belt is fifty-eight miles, and the widest section is three miles (fig. 2). The most productive quarries were only a few miles outside the city limits, and the names of towns near them became associated with the stone. Conshohocken and King of Prussia, for example, are situated along the Schuylkill River, which flows past the western edge of Philadelphia.[2]

The geological history of the limestone belt explains the beautiful color and durability of this material. Pennsylvania clouded limestone began its life as a sedimentary rock that underwent relatively light geologic pressure to reach its current state during the Cambrian period. Often it is found under brownstone laid down in the Triassic period. The term “marble” is a marketing fiction on the part of merchants who wanted to get good prices for the stone, which could be polished like imported marbles (fig. 3). True marbles are completely metamorphosed limestone and dolomite that have been subjected to extreme high pressure. One of its characteristics is its saccharoidal crystaline structure. Marble is made up of calcite (CaCO3) or crystalline calcium carbonate. When magnesium ions replace calcium ions, as is the case with the Pennsylvania clouded limestone, the result is dolomitic marble (MgCa)CO3. By contrast, limestone is made up of calcium carbonate and dolomite. The color of the metamorphosed limestone varies greatly. Gray was the most prevalent color quarried in Pennsylvania. Varying amounts of magnesia create equivalent variations of color throughout the limestone belt. The location of where this limestone metamorphosed determines its hue and the type of patterns found in it. Extraneous minerals cause color variations and affect the physical characteristics of the stone; some of these inclusions are quartz, iron, graphite, and several types of mica. Therefore, the colors and patterns of this dolomitic marble vary from quarry to quarry, and certain areas in the Philadelphia region became known for the visual attributes of the stone they produced.[3]

Traces of minerals such as magnesium give Pennsylvania clouded limestone a blue color, whereas graphite produces gray tones. In 1874, a leading geologist wrote:

The bluish-white streaked marble which adorns the door steps and window sills of the greater part of our houses comes from the limestone valley which, on either side of the Schuylkill, lies immediately north of the city. Originally formed by the accumulation of minute organic remains under deep sea water, subsequent changes have obliterated all traces of animal life, the streaks of carbonaceous material and the occasional specks of graphite alone remaining as witnesses. These same changes have altered certain strata of the limestone to the crystalline state known as marble.[4]

The most metamorphosed stone lies in the eastern portion of the limestone belt and gradually changes as it reaches the western edge in Lancaster County. Material not suitable for use as a marble was burned in kilns to produce lime for mortar, tanning, and agricultural purposes. The intense heat removed carbonic acid from the limestone leaving valuable calcium oxide, or quicklime, behind. During the eighteenth and nineteenth centuries, hundreds of kilns flourished in this region, and those from the Philadelphia area were renowned in America and abroad (fig. 4). Lime production slowed dramatically with the invention of Portland cement at the end of the nineteenth century. Although this had an adverse impact on local quarries, surviving accounts document their earlier output and describe the stone they produced.[5]

Geological Surveys

Two geological surveys from the nineteenth century are important in identifying deposits of Pennsylvania clouded limestone. The earliest survey was conducted by Dr. Gerhard Troost who published a short report on deposits and quarries of various types of rock that he discovered in the Philadelphia region in 1826. A hand-colored map accompanying his report depicts deposits of serpentine, limestone, gneiss, clayslate, and the eurite and transition formations (fig. 5). Troost described the limestone valley as one composed of “granular limestone, through which different strata of marble run, which is quarried in various places for building purposes, containing veins of cipolin (a granular limestone...containing veins of micaceous green talc), which characterize the marble used in Philadelphia.” The only quarry mentioned by name is “Anderson’s.” Troost also described a variety of soapstone that is probably the same material that forms the quoins of the Pennsylvania State House (Independence Hall) in Philadelphia (fig. 6). The panels on the north façade are limestone (fig. 7).[6]

Dr. Henry Darwin Rogers (1804–1866)—the first oYcial state geologist of Pennsylvania—catalogued several varieties of limestone quarried in the Philadelphia area. Appointed by the legislature in the 1830s, he spent decades taking samples of indigenous minerals and promoting his theories on ancient mountain formations of Appalachia. The initial purpose of this survey was to publicize the vast deposits of money-producing iron ore and coal in the eastern part of the state, but it documented the presence of other minerals including pseudo-marbles. In his Geological Survey of Pennsylvania (1858), Rogers noted that “marble of Potts Quarry” tended to be “clouded” or white. This descriptive term was also prevalent among marble dealers and architects who used “cloudy” to characterize the shadowy veining that ran through the stone. Rogers also noted that the “marble” outside of Philadelphia was “a highly metamorphic variety of...ordinary Magnesian limestone, crystallised and changed in tint by igneous action from within the earth.” His use of the term “marble” to refer to metamorphosed limestone undoubtedly reflects his knowledge of its commercial applications.[7]

Dr. Rogers spent twenty years surveying Pennsylvania with the help of several assistants who took mineral samples from all over the state. These samples were labeled, numbered, and put into a collection in the 1850s. This collection was later broken up and replaced with another assembled by the authors of the Second Geological Survey between 1870 and 1880. According to Dr. Robert Sullivan, Curator of Paleontology and Geology at the State Museum of Pennsylvania, the collection from the second survey is incomplete and in poor condition, but several numbered samples listed in the “catalogue of specimens” survive. This catalogue refers to the clouded limestone as “bastard marble,” indicating that its incomplete state of metamorphosis approaches true marble but falls short of the real thing.[8]

These samples were in storage for many years at the Academy of Natural Sciences in Philadelphia and were moved several years ago to the State Museum in Harrisburg, Pennsylvania. One sample is a “bluish limestone with bands of white limestone, and small flecks of mica” (fig. 8). The surveyors collected it at C. Earnest’s quarry, on the eastern side of the Schuylkill River between Norristown and Philadelphia. With its dark blue color, bright white veins, and passages of gray, this sample resembles the slabs on several opulent tables made in Philadelphia during the eighteenth and nineteenth centuries (see figs. 30, 31). A similar sample came from a quarry near Upper Merion Township below the village of King of Prussia on the western side of the river (fig. 9). The catalogue of specimens describes this piece as “white and blue marble with hydro-mica and pyrite.” Other samples are referred to as “bastard marble,” “limestone,” “(compact) limestone,” and “slaty limestone.” These varied descriptions reflect diVerent stages of metamorphosis, with “marble” being the hardest, and “limestone” the softest. The geologists also noted the variety of colors and color combinations that were available to the marble trade.[9]

The specimens assembled during the second geological survey are a benchmark for the study of Pennsylvania clouded limestone. Although the samples are very small, they document the colors and inclusions of stones that the surveyors considered representative of each quarry or area. By correlating the physical attributes of these samples with period descriptions of each quarry’s output, it is possible to pinpoint the source of stone used in some Pennsylvania furniture and architecture.

Ecclesiastical Monuments and Gravestones

Tombstones, grave markers, and monuments are another important resource for identifying the location and production methods of early limestone quarries in southeastern Pennsylvania. Many of the churchyards in outlying areas are near quarries. In addition to revealing possible sources for specific types of marble, the tombstones in these yards show what types of stone were available and fashionable at a given date. The latter is also true of churchyards in Philadelphia, although the stones in urban burial grounds probably reflect more diverse sources.

Founded by Welsh settlers in 1711, the Great Valley Baptist Church in Upper Merion Township has a churchyard with several early, ornate tombstones. These are important because the church is near the site of the Henderson quarries not far from Bridgeport in Montgomery County. Another nearby quarry is the Brooks quarry in King of Prussia; however, the earliest record of its existence is 1815. Two of the oldest tombstones (figs. 10, 11) are made of dark clouded limestone similar to the geological sample illustrated in figure 9. One has a baroque crest with carved scrolls (fig. 10), whereas the other has an arched crest and cyma-shaped elements on each side (fig. 11). The backs of both tombstones are quite rough (fig. 12). This may be evidence of quarrying with wedges, wherein slabs were split from larger rock masses before trimming.[10]

Another old burial ground further west is adjacent to Saint Peter’s Church, built in 1744 by Welsh congregants in the Great Valley in Chester County. There were several quarries in Chester County at Henderson Station, on Whitford Road, and near Downingtown, but there are no records of when they began excavating limestone. Early “quarrying” may have been done by farmers who sold oV exposed stone for lime burning and architectural elements. At Saint Peter’s, thirty-seven burial sites are eighteenth century, and the earliest is that of James David, who died in 1746 (fig. 13). His memorial is made of highly figured local limestone with blue-gray veining and has crossbones on the crest.

Other significant burial stones from Chester County quarries are in the churchyard of the Great Valley Presbyterian Church. Many exhibit a variety of tool marks indicative of their date. Most of the eighteenth-century stones are clouded limestone and relatively small. Some have backs with irregular facets left by flat chisels, whereas others have backs with small toothed marks in broad sweeping patterns (fig. 14). Stone cutters used toothed chisels of various sizes to produce this “corrugated” surface. The later burial stones are larger and lighter in color. Most of those dated between 1795 and 1819 have backs with parallel grooves that cross from left to right (fig. 15). These marks indicate that the stones were cut with abrasives and a sash-hung wire powered by water. The toothed saws used later in the nineteenth century performed the same function. This process became even more efficient with the advent of steam power in the 1820s.[11]

Several late eighteenth- and early nineteenth-century tombstones in the burial ground of the Augustus Lutheran Church in Trappe, Pennsylvania, have backs with uniform marks from a sash-hung wire or toothed saw blade. The color and figure of these stones varies, but most are white with gray and blue-gray patterns. Two of the most dramatic memorials are a massive altar tomb with a slab measuring four by six feet (fig. 16) and a tombstone with German script (fig. 17). Both are highly figured limestone with a deep blue and white pattern.

Limestone quarried outside Philadelphia made its way into the city during the early eighteenth century. Gloria Dei, or Old Swedes Episcopal Church, in Philadelphia has several important tombstones from the mid-eighteenth century. Built in 1698, Gloria Dei was a Swedish Lutheran church until 1845 when it became an Episcopal church. Three exquisite markers commemorating the interments of pastors are installed on the floor. The two earliest examples are gray and white with a very distinctive pattern (figs. 18, 19). Both have carved cherubim in the upper corners and brief biographies below. The marker for Andrew Ridman is dated 1708; however, it appears to have been produced at the same time and by the same stone cutter who made the marker for John Dylander in 1741. The third marker for Olamus Parlin is dated 1757. His stone is very dark and has a black field with dark blue veining. All of these markers are important in documenting the use of certain types of limestone at specific dates and for the prestige accorded this otherwise humble material. Although none of the stones in the churchyard are comparable, an eighteenth-century baptismal bowl with a nineteenth-century stand (fig. 20) appears to be made from the same limestone as the three early markers.

Processing Marble for Architectural Components and Furniture

As the aforementioned burial stones and monuments reveal, early marble slabs often have tool marks made by quarry laborers, mills, and stone cutters. Since technology changed over time, these marks can provide evidence of a stone’s processing date and, in the case of a furniture slab, its use on a given object. The originality of a table slab or other component that is easily removable can be diYcult to ascertain. A stone’s exposure to light and other environmental factors as well as compression marks and wear on the frame are equally important considerations.

During the eighteenth century, quarries sent stone cutters and marble dealers rough slabs that had been cleaved from the rock. Later, saw mills associated with quarries produced smooth slabs that stone cutters sawed and finished to their patrons’ specifications. Like the backs of early tombstones (see figs. 12, 21), the undersides of marble tops for tables often have uneven surfaces where the slabs broke away from the quarry wall (fig. 22). Most early stone cutters did not grind the surface down far enough to make the slab perfectly flat. Later slabs typically do not have irregularities or tool marks on their undersides owing to the use of steam-operated saws. Regardless of their date or intended function, marble slabs were generally cut in the same direction in which they were quarried.

Often specific tools can be associated with the marks on eighteenth- century table slabs. The Marble Worker’s Manual, Designed for the Use of Marble Workers, Builders, and Owners of Houses (1865) illustrates a variety of tools and implements used by stone cutters and describes their function (fig. 23). Most stone cutters followed the same basic procedures to process their slabs; they cut the stock into shape (fig. 23, nos. 61–62), hewed it with chisels and a mallet (fig. 23, nos. 2, 4, 19, 20, 64, and fig. 24a), dressed or “boasted” it with edge tools (fig. 23, nos. 8, 9, 27, 28, and fig. 24b), and finished it with chisels, rasps, and burin (fig. 23, nos. 13–16, 22–31, and fig. 24c). After performing these tasks, the stone cutter used pieces of sandstone to planish the exposed surfaces and a pumice stone and cushion to polish them. Eighteenth-century stone cutters usually tabled their slabs on the edges of the bottom surface so they would rest level on a furniture frame, but they did not make them flat like many of their nineteenth-century counterparts. On early slab tables, gaps between the stone and top of the frame are usually present. Most stonecutters did not planish the underside of such tops.[12]

Eighteenth-Century Quarries and Marble Dealers

Although many objects made of Pennsylvania clouded limestone survive, information on eighteenth-century quarries is scarce. Since records of lime burning exist from early in that century, it is probable that marble was a commodity at about the same time. The earliest quarries were in Whitemarsh Township and Harmanville, both in Montgomery County, Pennsylvania. Several quarries near Harmanville are mentioned in a 1714 deed wherein David Henry sold Thomas Coldee 150 acres of land east of Conshohocken Pike and south of Ridge Road. Philadelphia carver Anthony Wilkinson purchased this tract between 1720 and 1731.[13]

Bills and advertisements indicate that Wilkinson carved ship figureheads and sold marble pieces such as hearths. He may also have been the first entrepreneur to own a quarry and a marble shop in the city. In the November 2, 1727, issue of the American Weekly Mercury, Wilkinson offered a reward of forty shillings for a runaway servant named “Richard Peckford, a stone cutter by trade.” Wilkinson’s dual business evidently flourished since he continued to advertise carving and stone work during the 1730s and 1740s. When London-trained mason William Holland left Philadelphia for an extended trip to New York in 1739, he advised his customers to purchase marble from Wilkinson. Holland’s production included “Marble Chimney Pieces, Grave Stones, Mortars, Tables, Monuments and Steps, Pavements of All Kinds, [and] Hearths.” Two years later, the Pennsylvania Gazette reported: “MASON work done by Anthony Wilkinson, Ship Carver, in Water Street, just above the street commonly call’d Arch Street, and to be done of the best marble, in the quarry, he having lately found a vein of much better than has been formerly us’d.”[14]

It is conceivable that Wilkinson provided marble slabs and carved ornaments for local cabinetmakers. No documented example of his work survives, but the sideboard table illustrated in figure 25 is representative of the era in which Wilkinson worked. This example is from a large cabinet shop that produced several dressing tables, cabriole leg high chests, and other case and table forms (see fig. 26), most of which have details associated with Irish furniture. The shell and leaf ornament on the front rail is closely related to carving in the Pennsylvania State House. One of the carvers who submitted bills for this architectural work was Brian Wilkinson, Anthony’s son. The other carver, Samuel Harding, was one of the principal specialists employed by this cabinet shop.[15]

Although the marble top on the aforementioned table is replaced, the original slab may have resembled the one on an earlier frame (fig. 26). Made of deep blue and white clouded limestone, the top has an unusually complex molding on the front and sides (fig. 27). Its underside is planished, although rough impressions indicate that the stone was broken from the wall or floor of the quarry with a mallet and wedges (fig. 28). The back edge of the top has deep saw kerfs (fig. 29). Like the frame with the replaced top (fig. 25), the example illustrated in figure 26 has an unmistakable Irish aspect. The bulbous slipper feet and distinctive rail scalloping have parallels in other Irish-influenced forms from Philadelphia as well as the Rappahannock River Valley of Virginia. Based on its design, this slab table could date from the late 1730s.[16]

One of the earliest references to this table form in Philadelphia is the 1734 inventory of John Bryant who had “a Slab in a frame for a table.” Unfortunately, it is impossible to determine whether the top was imported or made in the region. Six years later, stone cutter Anthony Engelbreckt advertised marble “Chimney Pieces, Tables, Tea Boards, Coats of Arms, Tomb Stones, &c. made in the newest Italian and French fashion; and in the neatest and best Manner.” Although not conclusive, his reference to tables and tea boards suggests the production of furniture slabs. In 1738, the Philadelphia Gazette reported that cabinetmaker Joseph Claypoole made sideboards, a term used interchangeably for frames with marble slabs or wooden tops. Judging from advertisements placed by his son, Joseph almost certainly made frames for slabs. In the March 22, 1740, issue of the South Carolina Gazette, Josiah Claypoole reported that he had recently moved “from Philadelphia” and advertised “all sorts of Joyner’s and Cabinet-Maker’s Work” including “Frames for Marble Tables.” Less than two years before moving to Charleston, Josiah had inherited his father’s cabinetmaking business, stock, and “Implements of Trade.”[17]

Most of the surviving slab frames made by Philadelphia cabinetmakers before the mid-1760s have flat rails, occasionally ornamented with scalloping, moldings, or, more rarely, carving. To support the weight of the marble, these artisans relied on thick materials and sturdy mortise-and-tenon joints, the latter occasionally reinforced with vertical glue blocks. Cross-braces and corner braces also occur on some eighteenth-century examples.[18]

An elegant sideboard table attributed to the shop of Henry Cliffton and Thomas Carteret (fig. 30) displays an unusual method of indexing the top (figs. 22, 32). In the center of each rear leg is a round hole, presumably for a now missing metal pin that engaged a hole in the underside of the top. The stonecutter responsible for this slab probably used a bow-drill and “piercer” (a U-shaped bit) to hollow out the holes in the limestone. A few other eighteenth-century American slab frames have evidence for metal indexing pins, but most cabinetmakers relied on the tabled edges and the weight of the stone to register the top and prevent it from moving.[19]

The stone on the sideboard table shown in figures 30 and 31 appears by its color and complex figure to be from a quarry on the eastern side of the Schuylkill River, possibly one from the vicinity of Whitemarsh Township. During the eighteenth century, several proprietors including David Henry, Thomas Coldee, and Anthony Wilkinson managed these quarries. The slab on this table was cut from the rock with wedges and mallet, and both sides were roughly smoothed with chisels followed by a burin tool. To remove the burin marks on the upper surface, the stonecutter used sandstone or a similar abrasive. He also used crushed sandstone or sand worked with iron or wooden mullers and a coarse file to shape the edge. Then, he rubbed the stone with a succession of grinding materials that gradually became finer in consistency. Often polishers began by rubbing the stone with pieces of fired clay followed by pumice stone, lead filings with emery mud, English rouge, and for a brilliant effect, a linen cushion moistened with water and calcined tin.[20]

The stone cutter used toothed chisels to shape and smooth the bottom edges of the slab to make it sit level, but he did not remove the quarrying marks from the area inside the frame since it would not be visible. The section that drops into the frame is carefully sculpted to clear the inner edges of the rails and glue blocks (figs. 22, 32). This keys the stone to the frame so that it rests safely and securely

.

By the middle of the eighteenth century, Philadelphia cabinetmakers had established a relatively standard vocabulary for sideboard table frames. A manuscript titled “Prices of Cabinet & Chair Work/ Benjamin Lehman January 1786” lists the options for standard cabriole leg forms that were fashionable from the 1740s to the 1780s as well as straight leg examples that became popular by the late 1760s. Columns list from left to right prices for mahogany and walnut and the rates paid journeymen:

| Frames for Marble Slabs | |||||||

| Frame for Marble slab Marlborough feet with out Bases or Brackets about 4 feet long |

2.10.0 | 1.10.0 | 0.12.0 | ||||

| Do. with Bases and Brackets | |||||||

| Commode Rails | 3.10.0 | 0.17.0 | |||||

| Do. with plain Knees & Claw feet | 4.10.0 | 1.0.0 | |||||

| Do. with Leaves on the Knees & Carved Mouldings | 5.0.0 | 1.0.0 | |||||

| Do. 5 feet with 6 legs | 6.10.0[21] | ||||||

As the term “frame for a slab” implies, furniture makers typically made table bases to accommodate marble slabs. This was especially true of tables with elaborately shaped and/or molded tops, which were more difficult and more expensive to cut. The slab on the table illustrated in figure 33 is made of highly figured limestone with dark blue inclusions. To complement its complex shape, the owner commissioned a conforming frame with a drawer, a feature rarely encountered on eighteenth-century sideboard tables from the middle Atlantic region. With its lavish knee carving, gadrooned molding, and powerful claw-and-ball feet, this table is one of the finest Philadelphia examples in the rococo style.

The carving on the table is attributed to Nicholas Bernard and Martin Jugiez who first advertised in the November 25, 1762, issue of the Pennsylvania Gazette. Their firm received commissions for architectural carving from several prominent Philadelphians including Chief Justice Benjamin Chew, John Cadwalader, and Samuel Powell, and they worked for the city’s leading cabinetmakers including Benjamin Randolph, Thomas Affleck, and William Wayne. They also advertised “Carving in Wood or Stone and gilding done in the neatest Manner.” No stone carving can be attributed to Bernard and Jugiez, but their references to such work during the 1760s and 1770s imply that there was demand. Presumably their stone carving was sculptural rather than utilitarian. Like most of their competitors, they probably purchased marble slabs from local stone cutters.[22]

During the eighteenth century, several Philadelphia masons and stone cutters placed advertisements in Philadelphia newspapers. In addition to those mentioned earlier, these tradesmen included William Peters (1752), John Stanaland (1752), Brian Wilkinson and Son (1774), David Chambers (1780), William Stiles (1785), and William Payne (1798). At least one of these men employed slave labor. On July 16, 1752, the Pennsylvania Gazette reported: “A Likely young Negroe man, who has been employed for some years in the stone cutting business, country born, and has had the small pox, to be sold, or hired out by WILLIAM PETERS.” Peters’ advertised products, which included chimney pieces, slabs, tomb and head stones, and “other pieces of wrought marble,” suggest that his slave artisan possessed a great deal of skill.[23]

Nineteenth-Century Quarries

Many of the limestone quarries active during the nineteenth century were established much earlier. Philadelphia marble dealer James Traquair purchased one of Anthony Wilkinson’s. The former employed Italian sculptor Guiseppa Jardella and boasted that he had the “best quarry in this State [and produced]...twelve different kinds of beautiful clouded marble, which takes as high a polish as any of the Italian.” He also advertised “tombs, headstones, chimney pieces, side and currying tables [and]... monuments in the ancient or modern style.”[24]

Jardella and Christopher Hocker continued Traquair’s business until the middle of the nineteenth century, when Peter Dager and his son Daniel assumed ownership of the quarry. The business subsequently passed into the Potts family through marriage. Robert T. Potts and E. Channing Potts managed the quarry with great success until 1880, when the business became known as the Cedar Grove Marble Works. The quarry’s output was 12,000 cubic feet per year in 1858, and its most esteemed varieties of marble were “blue” and “mottled-white-and-blue.” Many houses near the quarry and in Philadelphia have surrounds made of marble similar to that from the Cedar Grove Quarry and nearby Fritz Quarry (figs. 34, 35).[25]

Wilkinson’s other quarries passed through several hands before Peter Fritz acquired them by 1830. Fritz was a prolific manufacturer of limestone mantles, monuments, and furniture slabs. An 1832 engraving of his marble yard on Race Street in Philadelphia shows large slabs leaning against his oYce and showroom (fig. 36). These slabs could be cut down and the edges finished to the patron’s specifications. As the illustration indicates, Fritz kept a large variety of stones and designs on hand. The limestone from his quarry was a very fine white and blue variegated type described during the period as “Pennsylvania clouded.”[26]

The Pennsylvania Land and Marble Company purchased the Fritz quarry together with a neighboring quarry in 1854. The company attempted to generate interest in the quarries by selling stock to investors and announcing plans to build a new railroad line to transport the stone and ore to the river where it would be loaded onto barges and shipped to the city. A stockholders’ report published in 1854 described the physical attributes of the land as well as its deposits of marble, limestone, and iron ore:

On account of the beauty of the location, and its springs of pure water, this place is visited by thousands of our citizens during the year. There is not a more fashionable place of resort for Pic-Nics, Sunday Schools, and other respectable associations in the vicinity of Philadelphia, than Spring Mills. There cannot be a doubt that these beautifully located lands will be surrounded with a dense and intelligent population; these lands will be worth more after the marble limestone and iron ore are taken oV, than they cost this company, with their rich mineral deposits included at the time of their purchase.

The Pennsylvania Land and Marble Company quarried “five specimens of Marble...in demand by the trade in all cities of the Union.” These included a “dark colored variegated chimney marble,” a “light colored variegated marble,” a “light clouded marble, used for all the purposes of building,” a “light clouded marble with white veins interspersed through it, a beautiful article,” and a “grey marble used for house and store fronts, columns, &c.” According to the stockholders’ report, local marble was selling for ten cents per square foot in 1854, whereas imported marble cost between two dollars and four dollars a square foot. Pennsylvania white marble was selling for one dollar per cubic foot, and one variety of blue and black marble was available for forty cents per cubic foot. The report also listed marble masons who would attest to the fine quality of the stone from the company’s quarries: J. Eckstein, Jr., Edwin Greble, Thomas Hargrave, Robert Harvey, J. E. & B. Shell, Oliver Ottinger, Henry S. Tarr, Adam Steinmetz, Lewis Thompson, J. Struthers and Son, S. F. Jacoby and Co., School & Faurest, and John Baird. Ultimately, the Pennsylvania Land and Marble Company failed. The old Fritz Quarry appears to have been nearly depleted when Dr. Henry Rogers conducted his geological survey in 1858.[27]

Like the Fritz Quarry, Marble Hall grew out of quarries established in the eighteenth century, most notably those founded by Thomas Moore in Whitemarsh Township by 1785. Marble Hall actually consisted of several quarries, “two stores, a marble mill, wheelwright, blacksmith shop and 42 houses.” Moore’s son Daniel Hitner expanded operations in 1813, and by the middle of the century, his sons Daniel O. Hitner and Henry S. Hitner added iron ore quarries and steam marble sawing mills. The largest quarry was 400 feet long, 60 feet wide, and 265 feet deep. Most of Marble Hall’s limestone was white or white with gray clouded veins. Many Philadelphia townhouses are fitted out in this white stone, probably because of its similarity to Italian Cararra marble. Marble Hall ceased to operate in 1870. By that date the extreme depth of the quarry made further excavation impractical and expensive.[28]

John Henderson’s quarry, established in Upper Merion Township in 1795, was esteemed for its white and blue limestone, often found in alternating layers. According to architect Thomas U. Walter (1804–1887), Girard College bought marble from Henderson Quarry in 1833 for the eastern flank of the cell, its portico, platform, and steps at a cost of one dollar per cubic foot (fig. 37). He specified “the whole to be of light blue marble similar to that used on the United States Mint and the Philadelphia Merchants’ Exchange” (fig. 38). The Second Bank of the United States was also constructed using stone from the Henderson Quarry (fig. 39).[29]

The nearby Brooks Quarry in King of Prussia was renowned for its light blue limestone, which appears on the north side of Girard College. This quarry also produced one of the largest slabs excavated in the Philadelphia region. This monumental stone was exhibited at the Chicago World Fair in 1898 and measured sixteen feet, two inches by six feet, nine inches.[30]

The Oakland Quarry in Chester County was opened for the sole purpose of supplying limestone for Girard College. Architect Samuel Sloan wrote “the Corinthian capitals and their sculptured work were from the Oakland quarries, their marble being well adapted to the purpose, on account of the compactness of its crystallization, thus enabling the artist to cut it into any desired form, and closely resembling in that respect, the Italian statuary marble.”[31]

Architects and builders also used locally quarried marble for residential projects. Numerous marble yards supplied them with stone for steps, water tables, lintels, fireplace surrounds, and other architectural components. An account book from the firm of Foust and Weaver (1854–1861) lists hundreds of orders for building details as well as tops for furniture: “one Italian slab for counter top $13.64,” a “wash stand top $6.50,” an “Italian wash stand top $22.00,” and a “second hand table top $6.00.” The reference to a “second hand table top” suggests that patrons often reused valuable marble parts, either with or without alteration. Anthony Quervelle paid Foust and Weaver $130 for “one white front, heads and sills” for his house on “Pine St. East of Sixth,” although he used imported marble for most of his furniture (fig. 40). The white stone ordered by Quervelle for his residence was less expensive than the blue variety.[32]

New Tastes for Old Stone

Just as furniture styles changed from the eighteenth to the nineteenth century, so did tastes for stone components for decorative objects. Although clouded limestone occasionally appears on neoclassical furniture (figs. 41, 42), its use diminished significantly owing to the popularity of Italian marble. White Carrara marble with slight veins of gray was considered ideal, but local stone of similar coloring was readily available and less expensive. The taste for exotic marbles increased throughout the nineteenth century, and local marble dealers maintained varied stocks. In 1853, James and Michael Baird advertised, “Carrara Statuary, Carrara Ordinary, Carrara Veined, Egyptian, or Black and Gold; Sienna, Levant, Brocatelle, Pyrenees, Bardilla and Lisbon.” This firm’s marble showrooms featured “130 patterns of mantels, slabs for the trade for tables, bureaus and workstands,” and their workshops had the latest steam-powered saws and abrasive devices to cut and polish their stone (fig. 43). The Bairds owned the largest marble yard in Philadelphia in the nineteenth century, but they received brisk competition from smaller firms, many located at Thirteenth Street and the terminus of Ridge Pike. Massive blocks of local stone arrived at Ridge Pike transported by large teams of horses. The Bairds and other major firms had equipment to cut blocks of stone into workable slabs, whereas smaller shops cut slabs into shapes and did edge work.[33]

The Decline of the Marble Business in Southeast Pennsylvania

By the middle of the nineteenth century, quarries in the Philadelphia region began to close. Many sites had become depleted or were so deep that the cost of quarrying the stone made them unprofitable. Some quarries, like those at Marble Hall, had steam- and water-powered lifts, but they eventually became impractical as well. Pennsylvania limestone also went out of fashion among furniture makers and consumers during the 1840s. Very few Philadelphia pieces from the Victorian era have locally quarried slabs (fig. 44), no doubt a result of the growing popularity and availability of foreign and exotic marbles.

Pennsylvania clouded limestone continued to be used by the building trades until regional quarries ceased production. Some quarries were reopened for special projects, like refurbishing the mantles at Independence Hall at the beginning of the twentieth century, but the business was essentially dead by the end of the nineteenth century. However, the adaptive reuse of architectural components made of Pennsylvania limestone today attests to the beauty, durability, and connotations of wealth and permanence associated with this important regional commodity.

ACKNOWLEDGMENTS

For assistance with this article, the author thanks Jeffery Adams, the staff of the Andalusia Foundation, Mark Anderson, Gavin Ashworth, Luke Beckerdite, Wendy Cooper, the staff of the Montgomery County Historical Society, the staff of the Historical Society of Pennsylvania, Susan Newton, Jeanne Soletsky, Earle Spamer, Dr. Robert Sulivan, Angelo Tartaglini, Charles Tonnetti, H. Mack Truax, and Brenda Wetzel. The author is especially grateful to Robert F. Trent for his insights, scholarship, and encouragement.

From the Travels of Peter Kalm as quoted in Edwin J. Hipkiss, Eighteenth-Century American Arts: The M. and M. Karolik Collection (Cambridge, Mass.: Harvard University Press, 1941), p. 96.

Unpublished manuscript, “Ores, Minerals and Geology of Montgomery County,” Montgomery County Historical Society (hereafter cited, MCHS), Norristown, Pennsylvania, p. 25.

Curt Chinnici interview with Earle Spamer, Geologist and Archivist for the Academy of Natural Sciences, Philadelphia, Pa., August 30, 2001. For a detailed analysis of Pennsylvania limestone, see Jocelyn Kimmel, “Characterization and Consolidation of Pennsylvania Blue Marble with a Case Study of the Second Bank of the United States, Philadelphia, Pennsylvania” (master’s thesis, University of Pennsylvania, 1996).

The quote is taken from a lecture given by Professor Henry Carvill Lewis (1853–1888) at the Franklin Institute and published as The Surface Geology of Philadelphia and Vicinity (Philadelphia, c. 1881). The lecture was “Read before the Mineralogical and Geological Section of the Academy of Natural Sciences of Philadelphia, November 25th, 1878.”

According to John Oldmixon’s British Empire in America (1708), the first North American limestone was quarried at Letitia Penn’s manor, Mount Joy. This quarry was probably in the vicinity of Port Kennedy. William J. Buck, History of Montgomery County Within the Schuylkill Valley (Norristown, Pa.: E. L. Acker, 1859), p. 37: “The census of 1840 shows the lime then manufactured in Montgomery County at about one third of that produced in the entire country.” For more on the lime burning industry, see Heinz J. Heinemann, The Lime Industry at Hope Lodge (Fort Washington, Pa.: privately printed, 1990).

Gerhard Troost, Geological Survey of the Environs of Philadelphia Performed by the Order of the Philadelphia Society for Promoting Agriculture (Philadelphia: H. S. Tanner, 1826), pp. 9, 10.

Ibid.

Sean Patrick Adams, Partners in Geology, Brothers in Frustration: The Antebellum Geological Surveys of Virginia and Pennsylvania (Baltimore, Md.: Genealogical Publishing Co., 1998). This book describes in depth the political and scientific worlds that coexisted when the Rogers brothers were working as state geologists during the mid-nineteenth century. Henry Darwin Rogers, Geological Survey of Pennsylvania (Philadelphia: J. B. Lippincott, 1858), p. 215.

Charles E. Hall, Catalog of Specimens, Second Geological Survey of Pennsylvania (Harrisburg, Pa.: Board of Commissioners for the Second Geological Survey, 1883), pp. 135, 139.

Several other tombstones and altar tombs in the churchyard are made of highly figured limestone, and their colors are typically dark gray and bluish gray. Altar tombs, which were common in the eighteenth century, consist of a large inscribed slab raised on four piers of stone or brick. Occasionally the sides are enclosed, but those in this churchyard are open.

Edwin Troxell Fredley, Philadelphia and Its Manufactures (Philadelphia: E. Young, 1867), p. 362: “Less than twenty-five years ago, all Marble was sawed by the friction of a saw without teeth, aided by sharp sand, pushed backward and forward by manual force. Now, Marble is sawed, rubbed and polished by steam power; and a block of Italian Marble has been converted into four hundred superficial feet of slabs in twelve hours.”

The Marble Worker’s Manual, Designed for the Use of Marble Workers, Builders, and Owners of Houses, translated by M. L. Booth (Philadelphia: Henry Carey Barid, 1865). “Planishing [is]...the process of giving a smooth finish to metal surfaces by a rapid series of overlapping, light hammerlike blows, or by rolling in a planishing mill” (Academic Press Dictionary of Science and Technology, www.harcourt.com/dictionary).

Unpublished manuscript, “Pennsylvania Marble Quarries Chronology c. 1714–1997,” MCHS. Excerpts from this paper appeared in articles by Edward Hocker in the Norristown Times Herald in 1930.

In July 1730, Anthony Wilkinson charged Captain Bignell (or Bicknell) £4.4 for a six-foot lion figurehead for the ship Tryall. The vessel was jointly owned by Samuel Powel, Jr. and Clement Plumstead (Powel Family Business Papers, Joseph Downs Library, Winterthur Museum.) Philadelphia joiner John Head credited Wilkinson £1.11.16 for a “marvel harth” on March 8, 1734 (Jay Robert Stiefel, “Philadelphia Cabinetmaking and Commerce, 1718-1753: The Account Book of John Head, Joiner” [Philadelphia: American Philosophical Society, 2001]). On November 22, 1739, the Pennsylvania Gazette reported: “MASONRY in all its Branches, is performed by WILLIAM HOLLAND, Mason, lately from London, viz. Marble Chimney Pieces, Grave Stones, Mortars, Tables, Monuments and Steps, Pavements of all Kinds, Hearths, &c. to be had at his Shop in Water Street, next Door to Mr. Stephen Beezley’s, Philadelphia. N. B. The above mentioned W. Holland is now at New York, fixing some Works for a Gentleman of that City, wherefore this is to desire all Gentlemen and others, to apply to Mr. Anthony Wilkinson, Ship Carver in Philadelphia, until he return, which will be in 14 Days from the Date of this Paper (if God permit)” (as cited on www.accessible.com). Unless otherwise noted, all eighteenth- and early nineteenth-century newspaper advertisements cited in the footnotes are from this database. South Carolina Gazette, March 22, 1740, as cited in The Arts and Crafts in Philadelphia, Maryland, and South Carolina, 2 vols., compiled by Alfred Coxe Prime (1929; reprint, New York: Da Capo Press, 1969), 1:163. Pennsylvania Gazette, May 21, 1741, as cited in Prime, comp., Arts and Crafts, 1:163.

For more on this Philadelphia cabinet shop, see Luke Beckerdite, “An Identity Crisis: Philadelphia and Baltimore Furniture Styles of the Mid-Eighteenth Century,” in Shaping a National Culture: The Philadelphia Experience, 1750–1800, edited by Catherine E. Hutchins (Winterthur, Del.: Winterthur Museum, 1994), pp. 254–81, figs. 9–15, 22–30, 33, 37–39. Brian Wilkinson also advertised marble and stonecutting, although the date when he began this business is not known. In the December 19, 1774, Pennsylvania Gazette, Brian Wilkinson and Son offered “chimney pieces of all kinds” and “Marble Stone cutting...in all its branches” (as cited in Prime, comp., Arts and Crafts, 1: 311).

For Irish influences on Virginia furniture, see Ronald L. Hurst and Jonathan Prown, Southern Furniture, 1680–1830: The Colonial Williamsburg Collection (New York: Harry N. Abrams, Inc. for the Colonial Williamsburg Foundation, 1997), pp. 305–8; and Ronald L. Hurst, “Irish Influences on Cabinetmaking in Virginia’s Rappahannock River Basin,” in American Furniture, edited by Luke Beckerdite (Hanover, N. H.: University Press of New England for the Chipstone Foundation, 1997), pp. 170–95.

William MacPherson Hornor, Jr., Blue Book: Philadelphia Furniture (Philadelphia: privately printed, 1935), p. 61. Pennsylvania Gazette, January 4, 1739. On May 18, 1738, the Pennsylvania Gazette reported: “This is to Certify that Mr. Joseph Claypoole, Joyner, has left oV his Trade; and has given his Stock and Implements...to his son [Josiah]...who has Removed...to the Joyners-Arms in Second-Street...where all Persons may be supplied with all Sorts of...Desks,...Chests of Drawers,...Dining Tables, Chamber Tables,... Tea Tables and Sideboards; he having the largest and oldest Stock of Timber in the Province, some of which have been in Piles near 25 years,...and a fine Sortment of the newest fashioned Brass Work Furniture, lately imported from London (as cited in Prime, comp., Arts and Crafts, 1:162, 163).

An early sideboard table formerly in the collection of Mrs. Lamont du Pont Copeland and another example with a history of descent in the Waln and Ryerss families (see Hornor, Blue Book, pl. 131) have cyma-shaped rails (the shaped sections are attached to flat inner rails). The latter table also has an applied skirt with relief carving.

The end rails of this table are similar to those on a high chest signed by Henry CliVton and Thomas Carteret and dated 1753 (Colonial Williamsburg Foundation). Furniture historian Alan Miller was the first scholar to suggest that this table was a product of their shop.

The Marble Worker’s Manual, pp. 52–54.

As cited in Hornor, Blue Book, p. 146.

For more on Nicholas Bernard and Martin Jugiez, see Luke Beckerdite, “Philadelphia Carving Shops, Part II: Bernard and Jugiez,” Antiques 128, no. 3 (September 1985): 498–513.

Pennsylvania Gazette, July 16, 1752 (Peters); Pennsylvania Gazette, May 15, 1755 (Stanaland); Pennsylvania Packett, December 19, 1774 (Brian Wilkinson and Son) (from Prime, comp., Arts and Crafts, 1:311); Pennsylvania Gazette, May 10, 1780 (Chambers); Pennsylvania Gazette, April 6, 1785 (Stiles); Porcupine’s Gazette, August 22, 1798 (Payne). David and William Chambers provided stone work for the Philadelphia townhouse renovated by John Cadwalader and his wife Elizabeth (Lloyd):

| A marble Chimney Piece and Hearth | ||

| for front Parlor | 16 1/3 feet @ 12/ |

0.9.16

|

| 1 do. for back do. | 17 1/2 feet @12/ |

0.10.7

|

| 1 do. for small do. | 13 1/4 fo @ 12/ |

0.7.19

|

| 1 do. for large front chamber | 20 1/2 feet @12/ |

0.12.6

|

| 1 do. for small do. | 15 1/2 feet @12/ |

0.9.11

|

| do. for back do. | 21 1/4 feet @ 12/ |

0.12.15

|

| setting 6 chimney pieces | @ 15/ |

0.4.10

|

| 10 iron clamps | @ 4 |

0.3.4

|

| lime |

0.3.9

|

|

| by 421/2 feet of old Marble | @ 5/6 |

11.12.10

|

| by cash |

0.15.0

|

|

|

£26,12,10

|

||

| Balance |

£408.2

|

Receipt for stone work for John Cadwalader, 1770, Cadwalader Collection, series 2 box 2, ch-cl, Winterthur Museum Library, Joseph Downs Manuscript Collection. William Payne reported that he was a marble mason from London and the “ORIGINAL INVENTOR and PATENTEE of the much improved SOAP-STONE STOVES.” He informed “his Friends and the Public, that they may be supplied with the above stoves, either plain or embellished with American or Italian Marble. Those stoves can be adapted to any size chimney, or attached to the most elegant chimney-pieces without interfering with the design, and are allowed to be an ornament to the handsomest drawing room....Likewise on hand, for sale, several new and secondhand American and Italian marble chimney-pieces ornamented and plain—Where also may be had, monuments, head and foot-stones, press...stones for printers, &c.” (Porcupine’s Gazette, August 22, 1798).

The information on James Traquair is derived from an article on him in the September 26, 1798, issue of Porcupine’s Gazette, as cited in “Pennsylvania Marble Quarries Chronology” and excerpts from that chronology published by Edward Hocker in the Norristown Times Herald (Edward Hocker, Collection of Norristown Times Herald Articles [MCHS, 1947], pp. 4, 5).

Ibid.

John Cole apparently took over the day-to-day management of Wilkinson’s stone cutting business following the latter’s death in 1765. In the April 4, 1765, issue of the Pennsylvania Gazette, Cole advertised “the marble cutting Business...in all its several Branches, at the Shop late occupied by Mr. ANTHONY WILKINSON, deceased; where all Persons that please to favour me with their Custom, may depend on having their Orders obeyed, with care and Dispatch.” Peter Fritz acquired quarries formerly owned by Wilkinson before 1832. For more on Fritz and his business, see Edwin T. Freedley, Philadelphia and Its Manufacturers (Philadelphia: Edward Young, 1859), pp. 360–66.

Freedley, Philadelphia and Its Manufactures, pp. 360–66: “The Fritz Quarry, recently purchased by the Pennsylvania Land and Marble Company, is an old quarry, and has produced a very fine white and blue variegated marble, known as the ‘Pennsylvania Clouded,’ formerly much used for mantels and chimney-pieces in old Pennsylvania houses of the better kind.” The Charter and By-Laws of the Pennsylvania Land and Marble Company (1854) reported:

Large importations of diVerent varieties of Marble, but principally veined Italian, are annually made from Leghorn, and sold on arrival at public auction, at prices varying from $2 to $4 per cubic foot. One establishment, that of Mr. John Baird, consumes annually over 15,000 cubic feet of Italian Marble. The quarries of JK and M Freedley, at West Stockbridge, Mass., supply a good quality of ordinary building Marble, which is extensively used in Philadelphia; and the Vermont quarries, particularly those at Rutland, from which the finest varieties of American Marble are obtained. It is not an unusual circumstance for quarry operators in New England to consign a cargo of Marble to this city on a venture; and as ventures do not always arrive exactly at the time of demand, the jobbers and dealers in Philadelphia can frequently purchase on terms so favorable, that they can in turn supply customers in the South and West with Marble in slabs cheaper that either could purchase it in block at the quarries. The wholesale dealers in this city, however, are generally owners of quarries—Mr. SF Prince is the only jobber who has no interest in any quarry.

As quoted in Freedley, Philadelphia and Its Manufactures, p. 362. An original copy of this document is in the Historical Society of Pennsylvania. The white marble was wrought from the Hitner quarries of Marble Hall near Barren Hill, and the less expensive black and blue marble was from the Lentz Quarry. Rogers, Geological Survey of Pennsylvania, p. 21.

William J. Buck, History of Montgomery County Within the Schuylkill Valley (Norristown, Pa.: E. L. Acker, 1859), pp. 63, 64.

See “Pennsylvania Marble Quarries Chronology,” p. 8. Thomas U. Walter, “Girard College Contracts and Diary, 1833–1836,” unpublished manuscript, Philadelphia Athenaeum, series 3.

“Pennsylvania Marble Quarries Chronology,” p. 8.

Samuel Sloan, Sloan’s Architectural Review and Builder’s Journal, July–December 1868 (Philadelphia: Claxton, Remsen & HaVelfinger, 1868–1870).

Foust and Weaver Account Book 1854–1861, account book n, 339, Historical Society of Pennsylvania.

See Freedley, Philadelphia and Its Manufactures, pp. 363, 364.