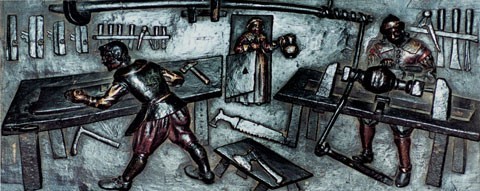

Carved panel depicting the interior of a woodworking shop, probably England, 1590– 1620. Oak. 14 1/2" x 28 1/2". (By permission of John Stent of Shere.)

Cabinet attributed to the Symonds shops, Salem, Massachusetts, 1679. Red oak, black walnut, and maple with white pine. H. 16 3/8", W. 17", D. 9 1/2". (Courtesy, Peabody Essex Museum; photo, Gavin Ashworth.)

Detail of the back of a drawer from the cabinet illustrated in fig. 2. Tears from riving are present along the lower edge of the back.

Chest, Boston, Massachusetts, 1660–1690. Oak, cedrella, and walnut with oak and white pine. H. 30 1/2", W. 45", D. 20 1/2". (Chipstone Foundation; photo, Gavin Ashworth.)

Detail of the upper rear rail of the chest illustrated in fig. 4.

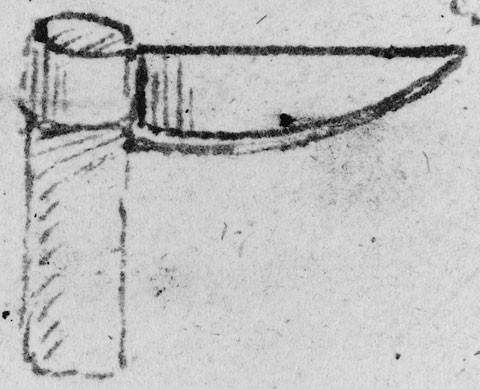

Randle Holme, drawing of a “lath axe” (froe), England, ca. 1688. (Courtesy, ©British Library Board.)

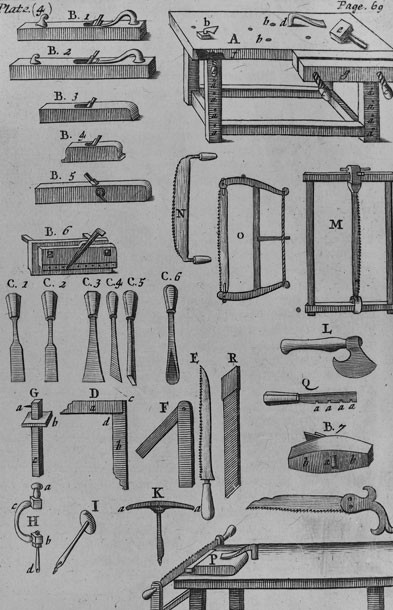

Workbench and tools illustrated on page 69 in the third edition of Joseph Moxon, Mechanick Excercises; or the Doctrine of Handy-works (1703). (Courtesy, Winterthur Museum Library: Printed Book and Periodical Collection.)

Holdfasts and bench hook being used to position a board for planing. (Photo, Gavin Ashworth.)

Bench hook being used to hold stock for planing. (Photo, Gavin Ashworth.)

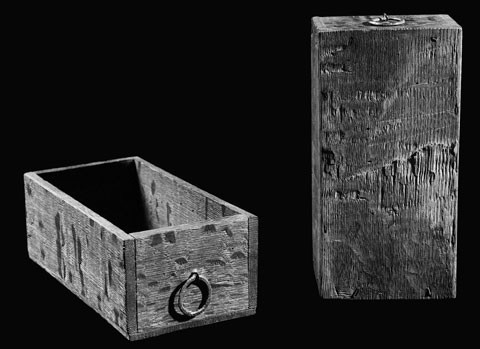

Detail of the bench hook marks on a seventeenth-century English box.

Cupboard, Boston, Massachusetts, 1675–1690. Oak, walnut, maple, chestnut and cedar with oak and white pine. H. 55 5/8", W. 49 1/2", D. 21 3/4". (Chipstone Foundation; photo, Gavin Ashworth.)

Back of the cupboard illustrated in fig. 11. The smoothing plane marks appear as concave undulations on the back panels.

Randle Holme, drawing of a smoothing plane, England, ca. 1688. (Courtesy, ©British Library Board.)

Smoothing plane, possibly New England, 1630–1700. Fruitwood and iron. L. 6 7/8". (Courtesy, Peabody Essex Museum.)

“Round” plane being used to mold a strip of wood to be cut into pieces for corbels like those on the cabinet illustrated in fig. 2.

Detail of the right corbel and side of the cabinet illustrated in fig. 2. (Photo, Gavin Ashworth.)

Plow plane being used to cut a groove in a framing member.

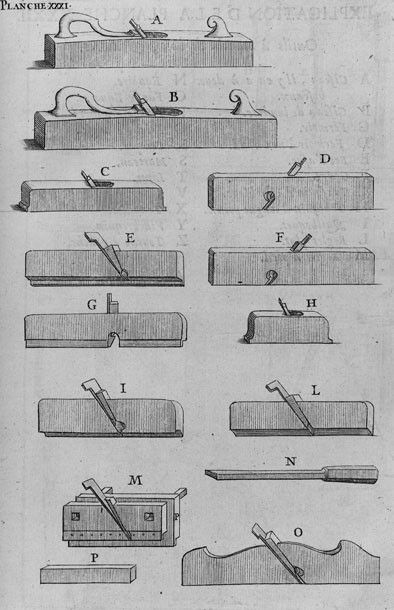

Planes and mortise chisel illustrated on plate 21 of Andres Felibien’s Des Principes de l’Architecture (Paris, 1676). (Courtesy, Winterthur Museum Library: Printed Book and Periodical Collection.) The plow plane is designated “M”.

Detail of the door of the cabinet illustrated in fig. 2 showing the plowed groove.

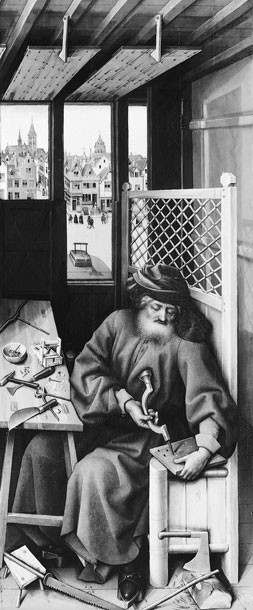

Detail of Annunciation Tryptich by Robert Campin and an assistant (possibly Roger van der Weyden), Netherlands, 1406– 1444. Oil on panel. Braces like the one shown here are still used today. (Courtesy, Metropolitan Museum of Art.)

Randle Holme, drawing of a brace and bit, England, ca. 1688. (Courtesy, ©British Library Board.)

Detail showing the cross-section of a pair of the half-columns on the cabinet illustrated in fig. 2.

Turning blank for half-columns and completed workpiece.

Chest attributed to John Thurston, Dedham or Medfield, Massachusetts, 1640–1650. Oak with pine. H. 31 3/8", W. 47 3/4", D. 21". (Courtesy, Museum of Fine Arts, Boston; Otis Norcross Fund.)

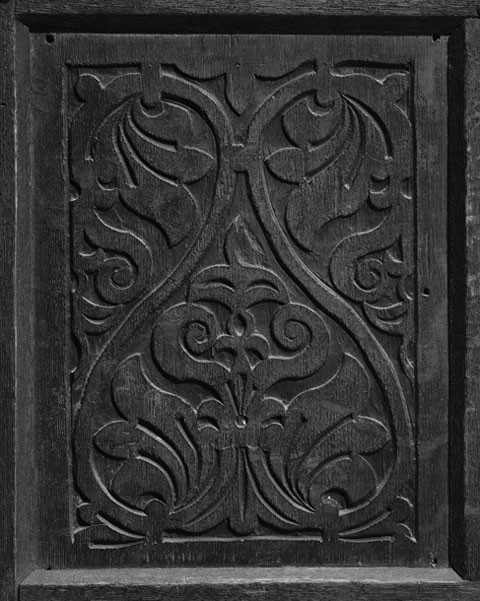

Detail of a carved panel on the chest illustrated in fig. 24.

Side of a cabinet being carved. The workpiece is nailed to a board secured to the bench with holdfasts. The carving design duplicates that on the side of the cabinet illustrated in fig. 2.

Detail of the left pillar of the cupboard illustrated in fig. 11.

Fragment of a cupboard attributed to the Savell shop, Braintree, Massachusetts, 1640–1670. (Courtesy, Winterthur Museum; photo, Gavin Ashworth.)

Detail of the door frame of the cupboard illustrated in fig. 28, showing the offset of the draw-bored holes.

Detail of the cabinet illustrated in fig. 2, showing a nail driven through the side into an interior partition.

Detail showing the nails used to construct the drawers in the cabinet illustrated in fig. 2

Detail showing the nail used to reinforce a split in the right side of the cabinet illustrated in fig. 2.

Chest attributed to the Savell shop, Braintree, Massachusetts, 1660–1680. Oak with white pine. H. 24 9/16", W. 51 1/2", D. 20 1/2". (Private collection; photo, Dan Gair.)

Chair table, southeastern Massachusetts, 1650–1700. Oak with pine and maple. Dimensions not recorded. (Private collection.)

Detail showing a mortising mistake on the chair table illustrated in fig. 34.

Chest attributed to John Norman, Sr., or Jr., Marblehead, Massachusetts, 1630–1680. Oak and pine. H. 27 3/4", W. 44 3/4", D. 20 3/8". (Chipstone Foundation; photo, Gavin Ashworth.)

Detail showing a mortising mistake on the chest illustrated in fig. 36.

Like most disciplines, furniture scholarship is profoundly influenced by prevailing social and cultural attitudes. During the late nineteenth and early twentieth centuries, Americans threatened by the rapid pace of modernization and growing population of European immigrants looked to the past for remedies to perceived social ills. The nostalgic and often fictional histories crafted to reinforce traditional American values have parallels in decorative arts literature from the 1920s and 1930s. Wallace Nutting’s romantic depiction of the makers, patrons, and context of “Pilgrim Century” furniture is typical. In 1924, he wrote:

There is an interesting variation in these [seventeenth-century Connecticut “sunflower”] chests...which clearly indicates that they were made to order, and that the feeling of the cabinet maker and his patron coincided in the thought of giving individuality to each piece. Thus we observe that the carving, the ornaments, the size and many other particulars are varied slightly. A chest, especially when designed as a gift, was regarded properly as appropriately marked by some peculiarity. It is this variety, so natural to a good workman, and so fine a stimulus in all artistic production, that the seventeenth century had and we have not. It is this feature which must be introduced again into American life. It is one thing to standardize the mechanism of automobiles. That may be possible and is certainly desirable. But we ought to distinguish between mechanics and artisanship. Unless we are to revive individuality in our characters as well as in our surroundings, true progress will be at an end. There is no stimulus in thinking, and no character development, if every household is to be furnished with standard articles.

Several of the attitudes expressed by Nutting and his contemporaries remain current today. Although many early furniture makers were ingenious, proficient artisans, most were concerned more with satisfying the demands of their patrons than self-fulfillment in a personal creative process. Indeed, the notion of “making art for art’s sake” is a modern construct with little relevance to the historic trades. A significant percentage of early artisans abandoned their trades as soon as it was financially viable, having experienced the numbing repetition of cutting thousands of mortise-and-tenon joints and countless feet of molding.[1]

In American Seating Furniture 1630–1730, Benno Forman asked the question: “Did...[a] craftsman really contemplate the beauty his work might result in and strive for it, or did he long for his twelve-hour day to end?” Salem, North Carolina, silversmith John Vogler’s diary entry stating that “my hands could always do what my mind dictated” certainly suggests that he was proud of his accomplishments, whereas the notebooks of London turner Nehemiah Wallington (1598–1658) paint a more dismal picture of his trade. On one occasion Wallington confessed: “At night after examination how I have spent the day, after a chapter read I went to prayer with my family; then I went into my shop to my employment more out of conscience to God’s commands than of any love I had unto it.” Regardless of their attitudes toward their work, all historic tradesmen shared one reality—they had to put a roof over their heads, clothes on their backs, and food on their tables. Achieving this goal required quick, efficient work methods and the ability to respond to local tastes.[2]

In “Eighteenth-Century Cabinet Shops and the Furniture-Making Trades in Newport, Rhode Island,” furniture scholar Mack Headley discusses problems inherent in elucidating procedures and shop arrangements for workmen of that period. Although less documentary evidence pertaining to seventeenth-century New England joiners and turners survives, a great deal of information can be extrapolated from court records, period artwork, and treatises such as Joseph Moxon’s Mechanick Exercises; or the Doctrine of Handy-works (1677) and Randle Holme’s Academie or Store-House of Armory and Blazon (1688). Using these sources, physical evidence on surviving furniture, and information gleaned from the use of period tools in reproduction work, this article will attempt to describe the activities and environment of seventeenth-century American furniture makers.[3]

Tools and Materials

Probate records are one of the best sources for determining a person’s trade, although some documents are more specific than others. One perplexing inventory is that of Martha Harding of Plymouth, Massachusetts. She died in 1633 leaving “Joyners tooles wth other things” valued at thirteen shillings, as well as “a servts time” worth six pounds. The name and trade of her husband and servant are not known, but it is likely that the former was a joiner. The 1651 inventory of Henry Birdsall of Salem, Massachusetts, lists “tooles for his trade” valued at two pounds, which suggests that his estate appraisers and the local community knew which trade he practiced. Typically, inventories that itemize tools and materials are the most useful in determining a person’s profession. Salem joiner John Symonds’ 1671 inventory listed “Joyners Tools benches and lare [lathe]” valued at £5.5.6, “2 Bedsteds almost finished” valued at three pounds, “Timber, planke & board” valued at £5.12, “part of a chest” appraised with other items, “a [pair]...of Jemmils” valued at five shillings, “Timber in the Woods” valued at £1.2 and “an apprentice of 17 years old who hath 3 year and 9 moneths and 2 weekes to serve.” Used primarily for chests and boxes, “jimmals” are hinges comprised of two linked rings spread apart like a cotter-pin. A 1630 English broadside lists “gimmals for chests” along with other types of ironware that would be useful for prospective New England settlers.[4]

Most seventeenth-century joiners had more than one piece underway at any given time. Although it is obvious that Symonds was working on two bedsteads, and possibly a chest, prior to his death, some inventories group unfinished work under a single entry. In those instances, values often provide a clue as to whether the work consisted of one or more objects. The £10.3 value placed on “New joynery worke unfinnished” in the 1672 inventory of Thomas Little, Sr., of Marshfield was sufficient for several pieces of furniture.[5]

Like tools and unfinished work, materials can also provide clues to an individual’s trade. Symonds’ inventory listed “timber, planke & board”—terms referring to wood in various stages of processing. “Timber” refers to wood in log form, “board” to thin, sawn stock, usually one inch thick, and “planke” to thicker sawn material, often two inches or more. The term “bolt” is less specific and can refer to joiners’ stock as well as carpenters’ clapboards and coopers’ staves. Manchester, Massachusetts, carpenter John Pickworth owned “a p[a]rcell of bowlts” in 1663, and Braintree, Massachusetts, joiner William Savell, Sr.’s inventory listed “joiners stuff and ceder boults” in 1669. Materials cited in the 1655 inventory of Salem turner Thomas Wickes include “flags” for chair seats, “timber” (presumably riven wood), boards, and planks: “one dwelling house with a shopp & barn & ground £35 in flagges £2/10 in working timber £1/10 in made ware as green Chayres, wheeles & Reemes £5 in plank & boards £1 in tooles £6.”[6]

Although inventories and treatises pertaining to the joiners’ and turners’ trades provide a wealth of information on tools, jigs, lathes, and other implements, the best depiction of a seventeenth-century woodworking shop is the carved panel illustrated in figure 1. Thought to date from the early-to-mid-seventeenth century, this panel depicts a joiner and turner at work—the joiner leaning into a stroke with his plane and the turner working on a large pillar at a pole lathe. Behind each man hang tools in racks on the wall. Tool historian W. L. Goodman suggested that the panel could be English, based on the type of handsaw between the benches. The placement of the saw, hatchet, and low bench in the center was intentional, since both trades use them. The joiner’s tools consist of planes (probably molding planes), chisels, a compass, a hammer, a bench hook, and a holdfast, whereas the turner’s consist of long gouges, chisels, and a large compass. The lathe is a slab with “stake” feet, and its top has a slot to accommodate the upright “poppets” that hold the workpiece. A wooden bracket in the ceiling supports the pole, which has a cord that runs around the workpiece and extends to the foot treadle under the lathe.[7]

The importance of this panel resides in its having been made by a seventeenth-century tradesman who worked in a similar shop rather than being an artist’s interpretation. All of the tools depicted in the carving are described in detail in Moxon’s Mechanick Exercises and appear in early New England inventories. More importantly, marks left by similar tools are present on the interior and exterior surfaces of surviving furniture, including cabinets and other joined case forms attributed to the Symonds shops of Salem.

The cabinet illustrated in figure 2 is in remarkably good condition having lost only one interior drawer, two small pieces of the molding forming the octagon on the door, and one of the triglyphs below. In typical New England joined fashion, all of its oak components were riven from a log. Although most of the stock has been planed smooth, some parts display tears from this splitting process (figs. 3, 31). Evidence of riving is usually found on surfaces not intended to be seen such as the undersides of table tops, cupboard shelves, chest and box lids, and the backs of case pieces (figs. 4, 5). Seventeenth-century inventories often list tools associated with riving—beetles, wedges, froes, and mallets— which was practiced by many different trades. Moxon’s treatise does not mention the froe (fig. 6), but Randle Holme referred to one in his discussion of cooper’s tools:

A Lath Axe [or froe], is an Iron Instrument like a Knife Blade, with a round thick back, having an Eye, into which a thick strong Handle is put, the edge standing outwards: With this, great Timber after it is cloven with the Maul and Wedges into small pieces, it afterwards cleaves them into Laths, Barrel Boards, and Pannels.[8]

Although inventory references to chisels, saws, and axes are also of little use in determining an individual’s trade, an entry for a workbench in conjunction with certain woodworking tools suggests that the deceased made furniture. Joinery required a bench, but carpentry did not. Regrettably, workbenches are rarely listed in probate documents, probably because most appraisers considered them a fixture in the shop rather than a “moveable.” The benches listed in John Symonds’ inventory are an exception, as are the “workeing benches” valued at five shillings in the inventory of Joseph Carpenter of Rehoboth, Massachusetts. Both Moxon and Holme illustrate a workbench, but neither describe it. Instead, their discussions focus on the use of the bench, its various appurtenances, and the process of joiner’s work (fig. 7).[9]

Certain implements can document an individual’s ownership of a workbench even if it is not listed in that person’s inventory. Moxon’s illustration (fig. 7) and the early pictorial panel (fig. 1) show two tools that are useless without a bench—the holdfast and bench hook. Therefore, the “broken holdfast & a bench hooke” valued at 1 shilling in the 1633 inventory of Plymouth, Massachusetts, carpenter Francis Eaton suggests that he owned a workbench and, by extension, made furniture.[10]

Holme described the holdfast (fig. 8) as “an Instrument of Iron, which being put into a loose hole of a Joyners Bench, and the Beak set upon any piece of Timber, with the Knock of an Hammer or Mallet upon the head of it, will cause the Work to ly fast upon the Bench, till the Work-man either Saw, Tennant, Mortess, or Plain it.” Used primarily for holding stock for planing, bench hooks are small iron implements with a toothed surface on one end and a wooden block at the other (figs. 9, 10). The block drops into the bench, leaving the teeth raised just above the top. The end of the workpiece is shoved against the teeth, which function as a stop for the planing action. Although most joiners worked with stock that was slightly oversized so they could trim away the indentations left by the teeth on the end grain, some period pieces have evidence documenting the use of a bench hook. The toothed marks (fig. 10) on a seventeenth-century English box, for example, are clear enough to indicate the size and shape of the hook used by its maker.[11]

John Thorp’s 1633 inventory is the first in Plymouth Colony that lists planes, one of the main tools that help determine if a tradesman was strictly a carpenter or if he also did joinery. Although carpenters used planes, joiners required a greater variety of sizes, shapes, and types. Thorp’s tools included “inboring planes,” a “joynter plane,” a “foreplane,” a “smoothing plane,” a “halferound plane,” a holdfast, three “broade chisels,” two “gowges & 2 narrow chisels,” three “Augers Inch & 1/2,” a “great auger,” an adze, a “felling Axe,” a handsaw, and “1 short 2 handsaw.” His appraisers also noted that “Will Palmer the [elder]...owes for a servt £2...pt of a fframe of an howse that is neere Wellingsly £2.”[12]

Thorp used the fore plane, smoothing plane, and jointer (fig. 7, b1, b4, and b2 respectively) to flatten rough boards, a critical step in furniture making. Moxon noted that the fore plane is used:

before you come to work either with the Smooth Plane, or with the Joynter. The edge of its Iron is not ground upon the straight, as the Smooth Plane, and the Joynter are, but rises with a Convex-Arch in the middle of it; for its Office being to prepare the Stuff for either the Smoothing Plane, or the Joynter, Workmen set the edge of it Ranker than the edge either of the Smoothing Plane or the Joynter.

As this reference suggests, the iron on a fore plane was typically set to take a thick shaving and remove stock quickly. Marks left by this tool are common on the backs, bottoms, and interior surfaces of period furniture (figs. 11, 12). “The Smoothing-Plane,” Moxon wrote, “must have its Iron set very fine, because its Office is to smoothen the work from those Irregularities the Fore-plane made.” Different styles of each plane were available during the seventeenth century. The “little short Plain” described and illustrated by Randle Holme (fig. 13) resembles Netherlandish gerfschaff and differs significantly from the smoothing plane shown in Mechanick Exercises (fig. 7, b4). Defined as “a plane for superficial planing,” gerfschaff were present in New England at an early date. John Ward (1652–1732) of Salem, Massachusetts, owned the example illustrated in figure 14.[13]

The jointer plane (see fig. 7, b2) is “made somewhat longer than the Fore-plane, and hath its Sole perfectly straight from end to end.” Moxon noted that its “office is to follow the Fore-plane, and to shoot an edge perfectly straight, and not only an edge, but also a Board of any thickness.” Holme described this tool similarly, but added “all the difference is in the Tote or Handle, which every Workman maketh according to his own Fancy, all other parts in the stock agreeing.” This supports the widely held theory that most tradesmen made the bodies, or stocks, of their planes. Merchants’ inventories and shipping records often list plane irons, but not “planes.” Making tools and parts integral to them was part of most apprentices’ training. Indentures often stipulated that the apprentice would receive a set of tools upon completion of his term. Although individual tools are rarely mentioned in period indentures, John Sparke of Bristol, England, agreed to give Humphrey Bryne “a Rule, a compass, a hatchet, a hansawe, a fore plane, a joynter, a smothen plane, two moulden planes, a groven plane, a paren chysell, a mortisse chesell, a wymble, a Rabbet plane,...six graven Tooles, and a Strykinge plane” when the latter signed his indenture in 1594.[14]

Molding planes, like the “inboring” and “halferound” examples noted in John Thorp’s inventory, are often listed in the inventories of seventeenth-century joiners who typically produced a greater range of moldings than carpenters. Holme stated that the terms “round” and “half-round” refer to the same plane. In period documents, round planes typically appear in conjunction with “hollow” planes. When used in tandem, these tools can generate a variety of moldings and architectural details (figs. 15, 16).[15]

Of all the planes listed in New England probate inventories, the plow (fig. 7, b6)—also referred to as a “joiner’s plow,” “wainscot plow,” or “grooving plane”—is most indicative of the joiner’s trade. The 1659 inventory of Plymouth, Massachusetts, joiner William Carpenter, Sr. lists “three Joynters,” “3 hand plaines,” and “one fore plain” valued at ten shillings and “Rabbeting plaines,...hollowing plaines, and one plow” valued at one pound. Plow planes (fig. 17) are used only for cutting grooves to receive panels and are absolutely necessary for performing joinery. They are fitted with a fence that guides the tool along a board as the narrow blade “plows” a groove in the edge of the stock. Moxon illustrated a plow plane in Mechanick Exercises, but the fence is shown on the wrong side of the tool. The engraver responsible for this image copied a plane depicted in Andres Felibien’s Des Principes de l’Architecture (Paris, 1676) but reversed the image (fig. 18). Most of the planes in Moxon’s plate of joiner’s tools are copied from this important French work.[16]

The door of the cabinet illustrated in figure 2 has grooves plowed through the tops of the stiles (fig. 19). This feature was a direct result of the plow plane’s design. The distance from the “toe,” or front, of the plane dictated that the joiner extend each stroke beyond the mortise in order to produce a full-depth groove to accept a panel. The exposed grooves on some period case pieces have been patched, but this invariably represents incorrect restoration.

As the indenture between Sparke and Bryne suggests, the “hansawe,” “mortisse chesell,” and “paren chysell” were principal tools of early joiners. Before cutting their mortises and tenons, most joiners used a marking gauge to inscribe layout lines on the edges of the framing parts. After determining the appropriate size of the joints, the tradesman set the gauge to match the width of his mortise chisel. Moxon described this process and noted that the joiner needed a “piercer,” or brace and bit (fig. 20), to bore the holes for the pins that secure the joint. “Its Office is so well known, that I need say little to it. Only, you must take care to keep the Bitt straight to the hole you pierce, lest you deform the hole, or break the Bitt.” Moxon also recommended that the joiner have several bits of various sizes. Holme’s description of the brace and bit (fig. 21) is similar, but he gives additional names for the tool: “for of some it is termed a Brace, others a Wimble, others a Wimble-Brace, and a Vambrace; in London it is generally termed a Piercer. It is used in Boring of Holes to drive Wooden Pins through Mortesses and Tennants in Joyners work.” In New England inventories, the term “wimble” appears more regularly than the other names for this tool.[17]

Although treatises like those written by Moxon and Holme are invaluable sources of information, they fail to mention many processes and techniques employed by period tradesmen. Consequently, this information must be surmised from evidence on surviving artifacts. The half-columns on the cabinet illustrated in figure 2 have subtle chisel marks indicating that a turner produced them on a pole lathe. Each of these appliqués is less than half-round (fig. 22), which suggests that the turner formed them from two equal size pieces of stock glued together with a thin strip of wood between them (fig. 23). After turning the workpiece, he separated the pieces and discarded the strip. Turners probably developed this process to reduce the chance of damaging the workpiece on the lathe. The center core provided material to engage the points of the lathe—the screw and pin—and protect the primary components of the turning blank.[18]

Evidence of the tools and techniques used for carving also survives on many pieces of seventeenth-century furniture. A joined chest attributed to Dedham and Medfield, Massachusetts, joiner John Thurston has foliate panels that retain many of the original layout lines (figs. 24, 25). Generated with a compass and awl, these marks established the basic pattern for Thurston’s design. The radius of his gouges and width of his chisels determined the precise shapes of each element. Some tradesmen used V-shaped parting tools for outlining, but chisels and gouges were faster and easier to control. Few shops used templates; joiners achieved symmetry through basic geometry and sheer repetition. Most of the carving on seventeenth-century American furniture is in relief rather than applied. Some relief-carved panels (fig. 25) have small square holes on the perimeter (these are usually visible on the outermost edges of panels that have shrunk). Presumably these are from nails used to attach the panel to the bench or to a board secured with a holdfast (fig. 26).

In Sylva, or a Discourse of Forest-Trees, and the Propagation of Timber in His Majesties Dominions (1664), John Evelyn wrote, “the greenest Timber is sometimes desirable for such as Carve and Turn.” Wood with a relatively high moisture content is softer and, in the case of some varieties, easier to cut than drier stuff. The use of green wood in seventeenth-century construction is most apparent in turned work like chair parts, table legs, cupboard pillars (fig. 27), “ball” feet, and other components that have shrunk from round to oval in cross-section.[19]

Joiners also used green timber for structural components. The framing members on many period objects display minor distortion from moisture loss, and the pins securing mortise-and-tenon joints often extend just above the surface. Presumably, joiners trimmed the pins flush originally. As the stiles and rails seasoned and shrank in thickness, the length of the pins remained constant. The resiliency of green wood also facilitated the use of draw-bored, mortise-and-tenon joints—a standard feature in seventeenth-century joinery. Most joiners drove the pegs through holes that were intentionally offset (the hole in the tenon is closer to the shoulder than the hole in the mortise) which made the joints draw together tightly (figs. 28, 29). Moxon recommended a difference “about the thickness of a shilling.”[20]

During the seventeenth century, nailed or “boarded” construction was a relatively inexpensive alternative, and occasionally an accompaniment, to joinery. The artisan who made the cabinet illustrated in figure 2 used nails to secure the bottom, top, and back boards to the sides and fasten the interior dividers in place. All of the nails driven through the top, bottom, and sides into the dividers are visible, and in some instances they disrupt the carving design on the sides (fig. 30). The interior nails securing the dividers are countersunk, so they do not interfere with the drawers as they are opened and closed.

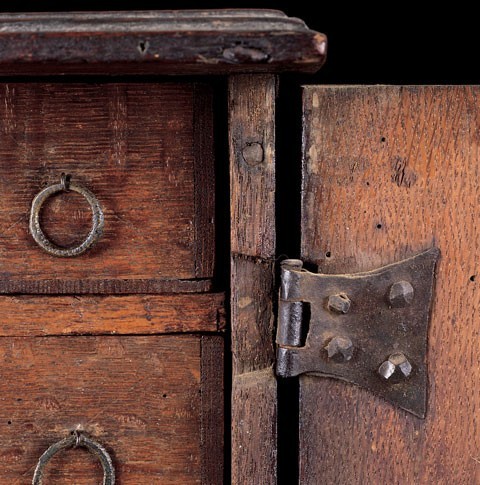

The joiner had to be careful in nailing the partitions, because oak tends to split easily especially when the stock is thin. Many joiners pre-bored nail holes with a tool Holme described as a “Sprig Bitt,...a thing like an Awl; having a four square Blade, with which holes are made in thin and narrow Stuff, to drive in small and slender...sprigs, Nails without heads.” The maker of the cabinet illustrated in figure 2 pre-bored the holes for all the large nails as well as the headless sprigs used to make the drawers (figs. 3, 31). Nevertheless, he split the side when nailing the hinges in place. Each leaf of the “dovetail” hinges was made for four nails, but the upper side leaf only has three nails even though the joiner bored a hole for a fourth (fig. 16). He evidently realized that the side was beginning to split—either from one of the three nails or from a nail driven through the top into the side—and chose not to use a fourth nail to secure the leaf. Instead, the joiner drove a nail into the front edge to repair the split (fig. 32)[21]

The Patron and the Maker

Like many examples of New England joinery, the cabinets attributed to the Symonds shop (see fig. 2) are commissioned objects that reflect the tastes of their owners as much as the style of their makers. Contracts for joiners’ work are rare, and most of the entries in surviving daybooks and other period documents are vague. An invoice from Wethersfield, Connecticut, joiner Peter Blin to Peter Bulkeley is typical. In 1681, Blin charged his patron three shillings for “a leaf of a table,” ten shillings for a chest, and two shillings for twenty-four trenchers. Ironically, one of the most detailed contracts is from the South, a region with very little furniture surviving from the seventeenth-century. On June 6, 1668, Accomack County, Virginia, joiner John Rickards agreed to make Anne Boote fifty-four pieces of furniture.

These presents bindeth mee John Rickards...to pay or cause to be paid unto Mrs. Anne Boote...These followinge works, Eight bedsteads, Nine tables & ten formes, five close Cupboards, five Courth Cupboards, one Courth Cupboard very handsome according to Mrs. Boote her directions, one close Cupboard also, Six Spinne wheeles, five chaire Tables, four chests this worke is to bee done by me Jno. Rickards...or else to forfeit one thousand lb. of Tobacco.

As furniture historian Robert Leath suggests, Mrs. Boote probably intended to sell most of the objects, but the “very handsome” court cupboard and “close” cupboard made to her specifications were almost certainly for personal use. The phrase “according to Mrs. Boote” implies that she contributed to the design of both objects.[22]

A 1681 suit involving Lynn, Massachusetts, joiner John Davis and John Tawley of Salem implies how their arrangement was intended to work. According to the court records, Tawley showed Davis a chest at the former’s house and asked him to make “two or three as good...for 25s.” A witness reported that Tawley said he “would rather Davis have his money than anyone else” and gave him five shillings as a deposit. Another deponent testified that he delivered four chests reputedly worth thirty shillings each from Davis’ shop to Tawley’s house. The transaction evidently had a somewhat violent ending, for Davis subsequently went to Tawley’s house, called him a “cheating knave,” and challenged him to a fight. Davis won the suit even though testimony showed that he took “hold of a wainscot chest in the room” and threw it “up and down...breaking several pieces of the font.”[23]

Several aspects of this suit shed light on the oral contract between the joiner and his client. Tawley made a conscious choice in patronizing Davis even though excellent joiners like Symonds were active in his home town at the same date. The fact that Tawley showed Davis a chest and requested two or three “as good” suggests that the former provided guidelines about the basic design and construction and the latter agreed to respond to his specifications. If the phrase “breaking several pieces of the front” means breaking several pieces off the front,” Davis’ chest probably had applied moldings and turnings similar to those on the cabinet illustrated in figure 2. Given the location of Tawley’s home, it is possible that Davis agreed to make chests more like those from Salem than from northern Essex County.[24]

Order of Work

Once the patron and joiner reached an agreement, the joiner began procuring materials. Although some joiners maintained a stock of logs and boards that could be reduced into parts, others obtained timber as need arose. The town of Ipswich, Massachusetts, granted certain tradesmen access to timber from the commons. In 1670, Freegrace Norton felled “3 trees for joynary worke.” Most towns restricted timbering to protect local resources.[25]

Descriptions of the most rudimentary aspects of seventeenth-century joinery—planing stock, framing, and executing decorative work—are absent in the written record. Similarly, no document specifies the amount of time required to perform any of these tasks, although it is obvious that joiners had to be efficient, or “workmanlike,” to survive in their trade. The repetitive nature of joinery, which revolves around frame and panel construction, and the use of unseasoned wood allowed most artisans to work at a relatively quick pace.

There are numerous records pertaining to the daily wages joiners charged their patrons. A 1640 court record from New Haven, Connecticut, outlines restrictions imposed on several trades:

In callings which require skill and strength, as carpenters, joyners, plasterers, bricklayers, shipcarpenters, coopers and the like [master]...workemen not to take above 2s6d a day in sumr, in wch men may worke 12 howers, butt lesse than 10 howers dilligently improved in worke cannot be accounted nor may be admitted for a full dayes worke, nor in winter above 2s a day, in wch at least 8 howers to be dilligently improved in worke....Butt all workemen in the former and like trades, who are not as yet allowed to passe under the names of [master]...workemen, not to take above 2s a day in sumr and 20d a day in winter as above expressed.

In November 1633, Massachusetts Bay governor John Winthrop complained that, “the scarcetye of workmen had caused [tradesmen]...to rayse their wages to an exessive rate, so as a Carpenter would have 3s the daye a labourer 2s6d &c.” After receiving complaints about “ill disposed [persons]...takeing excessive wages for worke, or unreasonable prizes for...necessary merchandizes or othr commodyties,” the Massachusetts Bay court passed a law that would punish anyone caught overcharging for labor or goods. At the same time, Winthrop remained concerned that excessive regulations would cause workmen to “remove to other places...or live by planting and other employments.”[26]

Regrettably, none of these references indicate how much time it took joiners to make a specific object or how they priced their wares. The 1674 inventory of John Legg of Marblehead listed “one new Chest” valued at twelve shillings, and “one new Box” at five shillings. Using the aforementioned wages, one might conclude that Legg’s chest required six days of labor and his box two. However, the cost of materials and ironwork, not to mention the fact that pay varied significantly depending on an individual workman’s skill, local demand, and myriad other factors, makes such calculations highly problematic.[27]

The number of tradesmen and distribution of labor in a given shop undoubtedly influenced the pace of work. In most instances, large shops probably turned out work faster than smaller ones, especially those of yeomen-artisans who devoted limited time to their trade. Nevertheless, it is possible to speculate on the time required to make certain objects by reproducing them using period tools and techniques. The author required approximately seventy-five hours to make a joined and carved chest similar to those attributed to the Savell shops of Braintree, Massachusetts (fig. 33). Preparing the framing stock required about two days; performing the joinery—cutting the tenons, chopping the mortises, plowing grooves for the panels, and boring pin—required approximately one day; and executing the carving required about six hours. Most of the materials and processes used to make this chest are described in detail in John D. Alexander and the author’s article, “Seventeenth-Century Joinery from Braintree, Massachusetts: The Savell Shop Tradition,” in the 1996 volume of American Furniture. Although both authors have spent a good deal of their lives making furniture using only period tools and methods, it is doubtful that they, or any of their modern contemporaries, are capable of working as quickly as seventeenth-century joiners.[28]

Evidence of mistakes made in constructing period furniture can also provide insights into how errors found in surviving furniture help illustrate how at least one tradesman organized his work. The chair table illustrated in figure 34 has an exposed, rectangular mortise in the turned section of one post (fig. 35). This indicates that the maker chopped his mortises before turning the posts. It would have been virtually impossible to make this error once the posts were turned, but the joiner could have oriented the post improperly ?while it was square in section and chopped the mortise in the wrong place.

A chest attributed to John Norman, Sr., or Jr., from Marblehead, Massachusetts, has evidence of a similar error (fig. 36). The upper rail has a mortise and two plugged pin holes to the right of the muntin separating the left and center panels (fig. 37). This indicates that the joiner chopped the mortise and bored the pin-holes before realizing that he was working on the wrong side of the layout line. He probably bored the pin-holes after chopping each mortise, or after chopping all the mortises in a given piece of stock. In the latter scenario, boring the pin-holes may have marked the piece “finished.” Most likely, the joiner discovered his mistake during a test assembly of the façade, cut a new mortise, and plugged the offending extra holes.[29]

As the documents and objects discussed in this article reveal, joinery was a complex trade requiring both proficiency and creativity. Some tradesmen prospered and established family dynasties that flourished for generations, whereas others enjoyed moderate success. Less fortunate artisans often moved from town to town in search of work or failed entirely. This is not to say that most early artisans suffered a miserable existence or that they despised working in their trade, but that their lives were far more challenging than we imagine today.

ACKNOWLEDGMENTS

For assistance with this article the author thanks John Alexander, Gavin Ashworth, Mark Atchison, Luke Beckerdite, Stuart Bolton, Victor Chinnery, Robert F. Trent, and the museums and individuals who provided photographs and access to their collections.

Wallace Nutting, Furniture of the Pilgrim Century (Boston, Mass.: Marshall Jones, 1924), pp. 53, 54, no. 18. Irving P. Lyon described Ipswich, Massachusetts, joiner Thomas Dennis as a “really great artisan” and suggested that the artisan’s forebears were joiners and “craftsmen of distinction...to judge by the standard of our Thomas.” Lyon also speculated about a theoretical ancestor of Thomas Dennis “plying his trade with integrity and skill.” Irving P. Lyon, “The Oak Furniture of Ipswich, Massachusetts, Part 1, Florid Type,” Antiques 32, no. 5 (November 1937): 230–37; “The Oak Furniture of Ipswich, Massachusetts, Part 2, Florid Type, Miscellaneous Examples,” Antiques 32, no. 6 (December 1937): 298–301; “The Oak Furniture of Ipswich, Massachusetts, Part 3, Florid Type, Scroll Detail,” Antiques 33, no. 2 (February 1938): 73–75; “The Oak Furniture of Ipswich, Massachusetts, Part 4, The Small-Panel Type,” Antiques 33, no. 4 (April 1938): 198–203; “The Oak Furniture of Ipswich, Massachusetts, Part 5, Small-Panel-Type Affiliates,” Antiques 33, no. 6 (June 1938): 322–25; “The Oak Furniture of Ipswich, Massachusetts, Part 6, Other Affiliates: A Group Characterized by Geometrical Panels,” Antiques 34, no. 2 (February 1939): 79–81. All of Lyon’s Antiques articles are reprinted in Pilgrim Century Furniture: An Historical Survey, edited by Robert F. Trent (New York: Main Street/Universe Books, 1976), pp. 55–78. Dennis’ birthplace and the name of his master are still unknown.

Benno M. Forman, American Seating Furniture 1630–1730: An Interpretive Catalogue (New York: W. W. Norton, 1988), p. 60. Forman’s chapter titled “Seventeenth-Century Woodworking Craftsmen and their Crafts” concerns many of the themes contained in this article. Frank L. Horton, founder of the Museum of Early Southern Decorative Arts, reported a phone conversation with a direct descendant of John Vogler who claimed to have the diary and who read Horton the aforementioned entry. Although the diary has never surfaced, Horton was convinced that it existed (Luke Beckerdite to Peter Follansbee, February 2000). As quoted in Paul S. Seaver, Wallington’s World, A Puritan Artisan in Seventeenth-Century London (Stanford, Ca.: Stanford University Press, 1985), p. 113. Nehemiah Wallington’s comments help dispel romantic notions about period tradesmen “painstakingly” laboring over their work in an effort to satisfy an artistic impulse, but his case was extreme. His father, John, Sr., was a warden of the Turner’s Company of London. Recognizing that his son and apprentice was depressed and suicidal, the elder Wallington paid the Turner’s Company to accept Nehemiah as a master after only two years of training.

This article was inspired by Mack Headley, “Eighteenth-Century Cabinet Shops and the Furniture-Making Trades in Newport, Rhode Island” in American Furniture, edited by Luke Beckerdite (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 1999), pp. 17–37. On page 17, Headley notes that “modern perceptions about historic trades often conjure up images of infinitely patient craftsmen working to the highest standards with no thought given to the time invested.” Joseph Moxon, Mechanick Exercises; or the Doctrine of Handy-works Applied to the Arts of Smithing, Joinery, Carpentry, Turning, Bricklaying (3d ed., London, 1703; reprint, Mendham, N.J.: Astragal Press, 1994). The first edition of Moxon’s work appeared in 1677. For more on Moxon and his publishing efforts, see Mechanick Excercises: on the Whole Art of Printing, edited by Herbert Davis and Harry Carter (2d ed., London; reprint, New York: Dover, 1978). Randle Holme, Academie or Store-House of Armory & Blazon (London, 1688; reprint, Menston, Eng.: Scolar Press, 1972). Holme’s work is available as a CD-Rom (Living and Working in the Seventeenth Century: an Encyclopedia of Drawings and Descriptions from Randle Holme’s original manuscripts for the Academy of Armory, edited by N. W. Alcock and Nancy Cox), and all subsequent citations are from the digital version. Holme’s work is divided into chapters, which are described as books. Subsequent references will give the book number followed by the page number. Alcock and Cox’s excellent introduction identifies many of Holme’s sources. Tool historians have traditionally focused more on Moxon than on Holme. See James M. Gaynor, Eighteenth-Century Woodworking Tools (Williamsburg, Va.: Colonial Williamsburg Foundation, 1997), pp. 99–116 .

For the Harding inventory, see Plymouth Colony Records Volume 1: Wills and Inventories 1633–1669, edited by C. H. Simmons (Camden, Me.: Picton Press, 1996), pp. 24, 25. Robert Charles Anderson, The Great Migration Begins: Immigrants to New England, 1620–1633, 3 vols. (Boston, Mass.: New England Historic Genealogical Society, 1995), 2: 854, 855. For the Birdsall and Symonds references, see Probate Records of Essex County, Massachusetts, 1635–1681, edited by George Francis Dow, 3 vols. (Salem, Mass.: Essex Institute, 1916–1920), 1: 143, 144 and 2: 247–50 respectively. The Oxford English Dictionary defines “lare” as a turner’s lathe, citing a 1611 reference from Randle Cotgrave, A dictionarie of the French and English tongues: “Tournoir, a Turne, turning wheele, or Turners wheele, called a Lathe or Lare.” The broadsheet is discussed in David Cressy, Coming Over: Migration and Communication Between England and New England in the Seventeenth Century (Cambridge, Mass.: Cambridge University Press, 1987), pp. 112–14.

For more on the Symonds shops, see Martha H. Willoughby, “Patronage in Early Salem: The Symonds Shops and Their Customers,” in American Furniture, edited by Luke Beckerdite (Hanover, N. H.: University Press of New England for the Chipstone Foundation, 2000), pp. 169–84; Robert F. Trent’s catalogue entry in The Joseph and Bathsheba Pope Valuables Cabinet, Christie’s, New York, January 21, 2000, pp. 18–21; and Robert F. Trent, “The Symonds Shops of Essex County Massachusetts,” in The American Craftsman and the European Tradition 1620–1820, edited by Francis J. Puig and Michael Conforti (Minneapolis, Minn.: Minneapolis Institute of Arts, 1989), pp. 23–41. Little’s inventory is dated April 4, 1672. Plymouth Colony Probate Records 3: 46, 47. Anderson, The Great Migration Begins, 2: 1189–92.

For the Symonds, Pickworth and Wickes inventories, see Dow, ed., Probate Records of Essex County, 2: 247–50; 1: 428, 429 and 1:241–43. Peter Follansbee and John Alexander, “Seventeenth-Century Joinery from Braintree, Massachusetts: the Savell Shop Tradition,” in American Furniture, edited by Luke Beckerdite (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 1996), pp. 81–104.

W. L. Goodman, The History of Woodworking Tools (London: G. Bell and Sons, 1964), pp. 147–48. On page 45 of American Seating Furniture, Forman argues that the panel does not depict a London shop because the joiner’s and turner’s trades were separated by regulation. The “slab” type lathe seen in this panel is not unusual, though Moxon depicts a framed construction for his lathes.

Holme, Academie of Armory & Blazon, 3:317. Holme mentions but does not illustrate an “Iron Frower,” which was used to cleave laths and wood. He considered this tool “necessary for a good farm or dairy.” In his section on joiner’s terms, Holme defines panels as “little cleft boards, about 2 foot high, and 16 or 20 inches broad, of these Wainscot is made.”

For more on the duality of the carpenter’s and joiner’s trades, see Robert F. Trent, Peter Follansbee, and Alan Miller, “First Flowers in the Wilderness: Mannerist Furniture from a Northern Essex County, Massachusetts, Shop” in American Furniture, edited by Luke Beckerdite (Hanover, N. H.: University Press of New England for the Chipstone Foundation, 2001), pp. 3, 4. In the present article, the term “joiner” is used to describe an artisan who made joined furniture while acknowledging that carpenters occasionally produced such goods. Simmons, ed., Plymouth Colony Wills and Inventories, 2: 349.

For the Francis Eaton inventory, see Simmons, ed., Plymouth Colony Wills and Inventories, 1: 41–44.

Holme, Academie of Armory & Blazon, 3:368.

Simmons, ed., Plymouth Colony Wills and Inventories, 1: 37–40. Thorp and his servant are mentioned twice in the colony’s records:

Jan 20 1632 Robt Barker servt of John Thorp, complayned of his mr for want of clothes. The complaint being found to be just, it was ordered, that Thorp should either foorthwith apparrell him or else make over his time to some other that was able to provide for him.

Aug 15 1633 Whereas Robt Barker had bound himself an apprentise to John Thorp in the trade of carpentry, the said Thorp being dead, Alice , his wife, hath turned over his time, wch will be exspired the first of April 1637 to William Palmer, nayler, of Plymouth, by free consent of the said Robert, the said William promising to instruct & teach him his said trade of nayling & at the end of his time to give him onely two sutes of apparell.

Records of the Colony of New Plymouth in New England, edited by Nathaniel Shurtleff and David Pulsifer, 12 vols. (Boston, Mass., Press of William White, 1855–1861), 1: 7, 16.

Moxon, Mechanick Exercises; p. 71. Gerrit van der Sterre, Four Centuries of Dutch Plane Making (Leiden, Netherlands: Primavera Press, 2001). Van der Sterre’s definition of the gerfschaff indicates a fore plane rather than a smoothing plane, putting Randle Holme at odds with some modern tool historians. Holme includes a second version of the tool, one with a convex sole, which he calls a “round” smoothing plane. On pp. 51–53, van der Sterre cites surviving “traditional” examples of these planes with many different sole shapes: “The sole can be straight, hollow, or rounded in cross-section, as well as straight or curved lengthways.” New England Begins: The Seventeenth-Century, edited by Jonathan L. Fairbanks and Robert F. Trent, 3 vols. (Boston, Mass.: Museum of Fine Arts, 1982), 3: 542–43. The sole of this plane is curved along its length, with a short flat section where the iron fits through the mouth. Holme, Academie of Armory & Blazon, 3: 367.

Moxon, Mechanick Exercises, pp. 69–70. Holme, Academie of Armory & Blazon, 3: 352. W. L. Goodman, “Woodworking Apprentices and their Tools in Bristol, Norwich, Great Yarmouth, and Southampton, 1535–1650” in Industrial Archaeology 9, no. 4 (November 1972), 376–411. Research by W. L. Goodman (see British Planemakers from 1700, 3d ed. [Mendham, N.J.: Astragal Press, 1993], pp. 13–16) and Donald and Anne Wing supports Holme’s claim that woodworking craftsmen often made their own plane bodies. Wing and Wing cite Francis Purdew (active 1704–1722) and Thomas Granford (active 1687–1715) as the earliest plane makers on record (Donald Wing and Anne Wing, The Case for Francis Purdew [Marion, Mass.: Privately printed, n.d.], pp. 9–22).

Simmons, ed., Plymouth Colony Wills and Inventories, pp. 37–40. Holme, Academie of Armory & Blazon, 3: 369.

For the February 21, 1685, inventory of William Carpenter, Sr. of Rehoboth, Massachusetts, see Simmons, ed., Plymouth Colony Wills and Inventories, pp. 361–67. Moxon, Mechanick Exercises, pp. 71–73. Moxon borrowed heavily from the French work of Andres Felibien (see Benno M. Forman’s introduction in Joseph Moxon’s Mechanick Exercises: or the Doctrine of Handy Works, edited by Charles F. Montgomery [New York: Praeger Publishers, 1970], pp. ix–xxvi). Felibien’s discussion of wainscotting differs from that of Moxon and Holme: “The strongest are those which are set into a furrow.”

Goodman, “Woodworking Apprentices,” pp. 376–411. Moxon, Mechanick Exercises, p. 94. Holme, Academie of Armory & Blazon, 3: 368.

Modern turners often use brown paper to help separate the glue line when breaking the finished turning apart. Animal hide glues like those used by period tradesmen are easily soluble with warm water or steam unlike modern yellow glues, which can be quite tenacious.

John Evelyn’s Sylva, or a Discourse of Forest-Trees, and the Propagation of Timber in His Majesties Dominions, &c. (1664). The reference cited here is from the text by Guy de la Bédoyère (1995) and cited with permission (www.british-trees.com/bibliography/silv.html).

Moxon, Mechanick Exercises, p. 88.

Holme, Academie of Armory & Blazon, 3: 368.

For the Blin reference, see Patricia E. Kane, “The Joiners of Seventeenth-Century Hartford County,” Connecticut Historical Society Bulletin 35, no. 3 (July 1970): 65–85. Bond of John Rickards to Anne Boote, June 6, 1668, Accomack County, Va., Orders, Wills &c. 1671–1673, fol. 231, as cited in Robert A. Leath, “Dutch Trade and Its Influence on Seventeenth-Century Chesapeake Furniture,” in American Furniture, edited by Luke Beckerdite (Hanover, N. H.: University Press of New England for the Chipstone Foundation, 1997), pp. 35–36.

Records and Files of the Quarterly Court Essex County, Massachusetts, edited by George Francis Dow, 8 vols. (Salem, Mass.: Essex Institute, 1911–1921), 8: 123, 124.

Ibid. Some tradesmen kept account books, as indicated by Ipswich, Massachusetts, wheelwright Richard Kimball, Sr.’s 1675 inventory listing £15.11 “due by Booke,” but none are known today. Kimball’s inventory is in Dow, ed., Probate Records of Essex County, 3: 16–19.

Photocopy in author’s possession with title page reading “Records of the Town of Ipswich volume 1, 1634–1674, copied by the Order of the Town of Ipswich, by Nathaniel Farley, 1890.”

Records of the Colony and Plantation of New Haven, from 1638 to 1649, edited by Charles J. Hoadly (Hartford, Conn.: Case, Tiffany and Co., 1857) pp. 36, 44. The Journal of John Winthrop 1630–1649, edited by Richard S. Dunn, James Savage, and Laetitia Yeandle (Cambridge, Mass.: Belknap Press of Harvard University Press, 1996), p. 102. Part of Winthrop’s concern was that “the evills...were...many spent muche tyme idlely &c: because they could gett as muche in four dayes as would keepe them a weeke...they spent muche in Tobacco & strong waters.” Records of the Governor and Company of the Massachusetts Bay in New England, edited by Nathaniell B. Shurtleff (Boston: Press of William White, 1853), 1: 160. Dunn et al., eds., Journal of John Winthrop 1630–1649, p. 345.

In a 1682 court case, Thomas Dennis reported that “Grace Stout bought a carved box with a drawer in it of him in 1679 and it had two locks.” For this, Dennis was paid 2 shillings 6 pence. Although this may have represented one day’s labor, the value of the locks makes any calculation problematic (Lyon, “The Oak Furniture of Ipswich Massacusetts,” in Trent, ed., Pilgrim Century Furniture, p. 56).

Follansbee and Alexander, “Seventeenth-Century Joinery from Braintree,” pp. 81–104.

For more on Norman, see Robert F. Trent, “The Marblehead Pews,” in New England Meeting House and Church, edited by Peter Benes as volume 4 of the Annual Proceedings of the Dublin Seminar for New England Folklife (Boston: Boston University, 1980), pp. 101–11.