Aryballos, Greek, Attic, late 6th century B.C. Terracotta. H. 2 7/16". (Courtesy, The Metropolitan Museum of Art, New York, Rogers Fund, 1923; image © The Metropolitan Museum of Art.) Molded in the form of three cockle shells, this small bottle held cosmetic oils.

Pitcher, Bernard Palissy and workshop, France, 1556–1590. Earthenware. H. 7 1/2". (Courtesy, Réunion des Musées Nationaux, Musée du Louvre, Paris; photo, J. G. Berizzi/Art Resource, New York.)

Fragment, cast of shells, Bernard Palissy and workshop, France, 1556–1590. Terracotta. L. 16 1/4". (Courtesy, Réunion des Musées Nationaux, Musée de la Renaissance, Écouen, France; photo, R. G. Ojeda/Art Resource, New York.)

Pair of silver shell dishes,

Paul de Lamerie, London, 1732. W. 5". (Courtesy, Christie’s New York; © 2006 Christie’s Images Ltd.) The realistic nature of these shells suggests they were cast from molds taken directly from a Pecten maximus shell.

Pickle stand, Derby porcelain factory, England, ca. 1765. Soft-paste porcelain. H. 14 1/4". (Colonial Williamsburg Foundation.)

Irish scallop (Pecten maximus). H. 5". This example is the deeply cupped right valve of the scallop. Note the rounded ribs in cross section and the large anterior ears or wings at the hinge.

A thick-walled shallow casting vessel is thrown on the wheel. The scallop shell is centered and pushed into the soft clay bottom. A thin coat of oil is applied to the scallop shell as releasing agent to prevent it sticking to the plaster.

Once the clay wall of the casting vessel has dried to leather hard, a mixture of plaster is slowly poured into the form over the shell, trying to avoid trapping air bubbles, and filled to the top.

Once the clay wall of the casting vessel has dried to leather hard, a mixture of plaster is slowly poured into the form over the shell, trying to avoid trapping air bubbles, and filled to the top.

Once the clay wall of the casting vessel has dried to leather hard, a mixture of plaster is slowly poured into the form over the shell, trying to avoid trapping air bubbles, and filled to the top.

After the plaster cures, the clay walls of the casting vessel are peeled away and the scallop shell is removed from the mold. Once dry, the mold is ready for casting.

After the plaster cures, the clay walls of the casting vessel are peeled away and the scallop shell is removed from the mold. Once dry, the mold is ready for casting.

To begin the casting process, the porcelain clay slip is poured into the mold.

To begin the casting process, the porcelain clay slip is poured into the mold.

It is essential that the mold be filled to the edge of the casting. The soft clay wall at the rear of the mold keeps the slip from running out and aids in the “pouring off” of excess slip.

The filled mold is left to stand for several minutes while the plaster body absorbs moisture from the porcelain slip. The thickness of the cast depends on how long the slip remains in the mold before it is carefully poured away.

The filled mold is left to stand for several minutes while the plaster body absorbs moisture from the porcelain slip. The thickness of the cast depends on how long the slip remains in the mold before it is carefully poured away.

After the cast shell hardens, the soft clay retaining wall is peeled away and the shell is carefully removed from the mold.

After the cast shell hardens, the soft clay retaining wall is peeled away and the shell is carefully removed from the mold.

After the cast shell hardens, the soft clay retaining wall is peeled away and the shell is carefully removed from the mold.

Two other plaster molds were needed to create the remaining major components of the pickle stand. A one-piece mold was used to create the top cup for the stand. A two-piece press mold was used to form the central stalk.

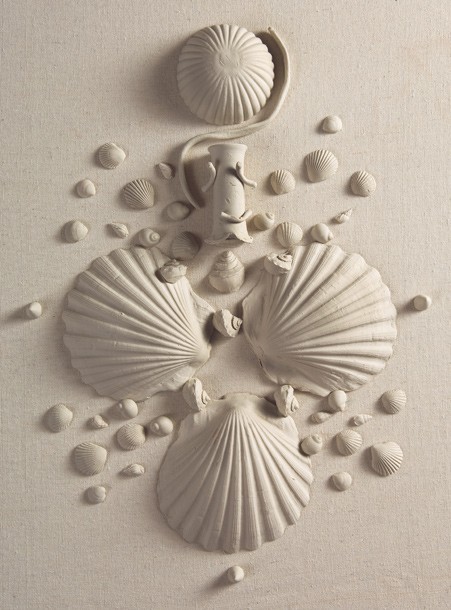

The molded major components of the pickle stand at the leather-hard stage.

The creation of the various smaller shells, which represent an encrusted marine environment, requires a number of small press molds taken directly from natural shell specimens. (The examples shown here were selected for demonstration purposes and do not necessarily correlate with all the smaller shells used on the original Bonnin and Morris pickle stand.) To create the molds, the shells were carefully pressed into prepared slabs of soft porcelain clay.

The porcelain slabs were allowed to dry and subsequently fired to bisque temperature. A small ball of porcelain clay was pushed into the molds and extracted to create the necessary clay shells. The porous nature of the bisque porcelain allowed the casts to be removed from the mold right away.

The porcelain slabs were allowed to dry and subsequently fired to bisque temperature. A small ball of porcelain clay was pushed into the molds and extracted to create the necessary clay shells. The porous nature of the bisque porcelain allowed the casts to be removed from the mold right away.

The porcelain slabs were allowed to dry and subsequently fired to bisque temperature. A small ball of porcelain clay was pushed into the molds and extracted to create the necessary clay shells. The porous nature of the bisque porcelain allowed the casts to be removed from the mold right away.

A variety of working molds were necessary to create the repertoire of smaller shells similar to those used on the Bonnin and Morris pickle stand.

Representations of the small tube worms were hand-modeled as clay coils. The openings were made using a flat metal blade.

Representations of the small tube worms were hand-modeled as clay coils. The openings were made using a flat metal blade.

Michelle Erickson laying out the molded components of the pickle stand before assembly.

A schematic representation of some of the clay components of the pickle stand. Each of these objects would have to be prepared and ready at the time of the assembly. More than seventy separate elements were required to re-create this object.

The assembly of the clay components begins with the orientation of the three large scallop shells. The ears of the scallop shells are cut away before they are fitted together to form the base.

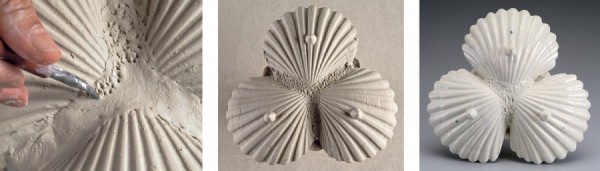

A triangular clay strip acts as a fillet between the shells, providing an integral structural connection. Drops of slip are used to strengthen the adhesion and the strip is worked into the crevices.

A triangular clay strip acts as a fillet between the shells, providing an integral structural connection. Drops of slip are used to strengthen the adhesion and the strip is worked into the crevices.

The clay fillets are stippled to simulate fossil coral. The stippling also helps reinforce the structure of the stand. The base from the original is shown at the far right.

The inside edges of the scallop shells are cleaned with a wet sponge.

The upper crevices between the scallop shells are filled with small clay strips and stippled. The stalk is now adhered to the center of the scallop shells. Note the flange at the bottom of the stalk, which aids in the attachment. The flanges are hand-worked down over the shells to form a secure bond.

The upper crevices between the scallop shells are filled with small clay strips and stippled. The stalk is now adhered to the center of the scallop shells. Note the flange at the bottom of the stalk, which aids in the attachment. The flanges are hand-worked down over the shells to form a secure bond.

The top cup is joined to the stalk using slip. As with the base fillets, the stalk is stippled to simulate fossilized coral, a sample of which is shown.

A strand of seaweed is represented by a flattened coil of clay wrapped around the stalk. This device serves to conceal the joins of the stalk at the base of the top cup and provides a point of attachment for the small snail-like shells as they ascend the column.

A strand of seaweed is represented by a flattened coil of clay wrapped around the stalk. This device serves to conceal the joins of the stalk at the base of the top cup and provides a point of attachment for the small snail-like shells as they ascend the column.

The pickle stand is ready for the attachment of the small shells. Using the originals as a general guide, a group of cockle shells is built up along with a tube worm. Drops of slip are used to help secure these shells.

The pickle stand is ready for the attachment of the small shells. Using the originals as a general guide, a group of cockle shells is built up along with a tube worm. Drops of slip are used to help secure these shells.

The pickle stand is ready for the attachment of the small shells. Using the originals as a general guide, a group of cockle shells is built up along with a tube worm. Drops of slip are used to help secure these shells.

A final cockle shell is placed in position. Note that this shell consists of two separately molded shells that are joined to simulate a live cockle.

After the three major clusters of cockle shells are arranged, the smaller marine shells and additional tube worms are placed on the stalk.

A needle tool facilitates the delicate placement of the smaller shells.

The final stage in the assembly is the placement of the cone-shaped feet, using a photograph of the original pickle stand base as a guide. The stand has to be turned upside down for this final step.

The final stage in the assembly is the placement of the cone-shaped feet, using a photograph of the original pickle stand base as a guide. The stand has to be turned upside down for this final step.

A view of the base of the assembled pickle stand next to a notated photograph of an original. Note the high definition of the rounded ribs and the presence of the circular growth rings.

Overall view of the assembled pickle stand in leather-hard state.

A pair of pickle stands in

biscuit and leather-hard states after the Bonnin and Morris originals juxtaposed next to a ca. 1765 Bow porcelain model. The additional stages of the finishing process include a biscuit firing, followed by the application of blue decoration and a final glaze firing. The unfinished stands would lose approximately 15 percent of their size during the two firings.

This essay illustrates the process of creating a Bonnin and Morris–type pickle stand. Clearly the most ambitious of all the ceramic forms made at the American China Manufactory, these stands have become the icons of the factory’s production. It is perhaps no accident that of the nineteen surviving objects from the factory, six are pickle stands—a relatively high proportion. Although many other vessel forms were produced, these stands must have been especially appreciated for their complexity, delicacy, and intrigue. A cynic might counter that this disproportionate survival rate could reflect the stands’ relative uselessness as functional tableware. Whereas teapots, punch bowls, teabowls, and saucers succumbed quickly to the rigors of daily use, perhaps pickle stands were used only on special occasions, or simply as ornamentation, and thus were relegated to protected shelves for much of their lives.

Analysis of the vessel forms has been deemphasized in the evaluation of products produced by the American China Manufactory in favor of the analytic and scholarly research on the physical and chemical characteristics of the clay bodies used there.[1] Indeed, the identification of a clay body’s constituents is a quick and quantitative way to help determine the origin of newly suspected porcelain examples. However, less attention has been directed toward understanding other identifying attributes of the factory, especially its production technology and the decorative elements and stylistic attributes of its products.

Because of their complexity and idiosyncratic nature, the pickle stands are particularly fertile ground for investigating certain production techniques used in the Philadelphia operation. As this essay will illustrate, more than seventy molded elements went into their construction. Since the form is a direct take on similar English porcelain factory models, our efforts explore what identifies the Bonnin and Morris pickle stands as distinctly Philadelphian and, hence, distinctly American.

Comparatively little has been written about the specific manufacturing techniques used by the different porcelain factories.[2] In contrast, much more has been written about those used by the eighteenth-century pottery industry.[3] Molds were the key technology behind the production of porcelain. Porcelain factories were industrial enterprises—repetition, speed, and consistency were essential and the use of molds maximized all three. Studying the various molding strategies used by eighteenth-century English porcelain factories has been hampered by the fact that very few working molds have survived. Recent excavations at the Bow porcelain factory undertaken by the Museum of London have recovered numerous fragments of plaster molds that one day might add a new chapter to the field’s history.[4] Not a single mold fragment was uncovered during excavations of the American China Manufactory site, however, even though such items were clearly necessary, especially given the numerous marine shells needed for the pickle stands.

Shells have always been an integral part of the human experience—as utensils, cutting tools, and for personal ornamentation. They have been integrated into the symbols and myths of many cultures and occupy a primary place in the aesthetic vocabulary of Western art. Their use in eighteenth-century porcelain compositions was widespread.

The relationship with shells and pottery is as equally interconnected. Shells served as models for early molded forms in Greek and Etruscan ceramics (fig. 1). The very term porcelain is derived from the Italian word porcellana, or cowrie shell.[5] When examples of Chinese porcelain first appeared in Europe, in the fourteenth century, many believed that the substance was made from shells. Such was not the case, but mollusk shells have been ground up and used as a tempering agent in both the New and Old World traditions for thousands of years.

The contributions of French Renaissance potter Bernard Palissy (1509/10–1589/90) played a visible role in the history of molding natural life forms as ceramic expressions.[6] Famed for his innovations in the so-called rustic ceramics, Palissy perfected the process of preparing casts of shellfish and other marine life that he incorporated into his earthenware creations (fig. 2). Making these casts was a direct procedure—the subject shell was partially pressed into a prepared slab of clay, creating a negative mold. The clay slab was then fired and from the resultant mold numerous pressed casts could be taken. Palissy and his followers used this molding technique to create the fabric of his large-scale grottoes (fig. 3). He also used casts of shells in the composition of his varied ceramic vessels.

During the eighteenth century shells continued to inform ceramic design as well as other media. Early English porcelain shares lineage with fashionable silver designs. The incorporation of fanciful marine elements was embraced by many silversmiths working in the rococo style. Paul de Lamerie (1688–1751), one of the leading English silversmiths in the first half of the 1700s, is renowned for his technical proficiency and innovative designs using bold organic forms; a pair of silver scallop shells with attached barnacles, obviously cast from life, foreshadows later porcelain examples (fig. 4).[7]

The connection between silver and porcelain design is manifest by an example offered by London master silversmith Nicholas Sprimont (1716–1771), who in 1744 became manager of the newly founded Chelsea porcelain factory. From a pair of silver gilt crayfish salts he made for Frederick (1707–1751), Prince of Wales, Sprimont executed similar versions in soft-paste porcelain.[8] Another noteworthy marine-inspired composition produced at the Chelsea factory is a tripartite open salt or sweetmeat dish composed of three large clamlike shells encrusted with corals and other, smaller shells.[9]

The widespread adoption of these sweetmeat dishes, especially in this tripartite form, reflects a mid-eighteenth-century change in dining fashion with the interest in pickled fruits and vegetables inspired by French cuisine. To understand—solely from a design perspective—how this form propagated so quickly, it is important to recognize the recurring theme of imitation and plagiarism in the porcelain world. English porcelain factories shamelessly appropriated European and Asian designs, making only minor alterations.

The creation and marketing of domestic-made porcelain was based on the concept of offering an improved version of a foreign competitor’s product at a favorable price. The standard was Chinese porcelain, imported into Europe beginning in earnest in the late sixteenth century. The establishment of the early-eighteenth-century porcelain factories in France, Germany, and Italy revolved around the imitation and replication of this highly prized Asian import. The practice of copying continued in the 1750s and 1760s, when the early English porcelain makers sought out design sources from both Chinese and subsequent European products. By the time Gousse Bonnin and George Anthony Morris’s workforce began producing porcelain at the American China Manufactory in 1770, the tripartite pickle stand had long become de rigueur and was produced in some version by nearly every English porcelain factory.

Despite being a common form in English soft-paste porcelain, the pickle stand was the single most expensive object produced by the Bonnin and Morris factory, appearing in one price list at a cost of fifteen shillings.[10] The vessel form closest in price was the openwork fruit basket, at ten shillings. By way of comparison, a small sauceboat might have sold for as little as one shilling.[11] In addition to sheer cost, a measure of the pickle stand’s significance can be gauged by the fact that it was this form that the wealthy Philadelphia merchant John Cadwalader and his wife, Elizabeth, who had commissioned a pair of them, chose to have decorated with their cipher (the conjoined initials JEC) and the insignia of the arms of their respective families (see Plates 18, 19).

Hilary Young has noted the striking similarities between the shell-encrusted pickle dishes and stands made at Bow, Bristol, Chelsea, Plymouth, and Worcester.[12] The pickle stands, for example, all use a similar vocabulary—a base formed by three open mollusk shells and further adorned with applied smaller shells, corals, and other marine encrustations. The stands range from fairly simple compositions to extremely elaborate, multitiered centerpieces (fig. 5). Few dispute that all the Bonnin and Morris vessel forms were appropriations of firmly established English prototypes, so how were these wares interpreted at the Bonnin and Morris factory? In their 1770 advertisement for workers, Bonnin and Morris acknowledged that their operation depended on those proficient in “throwing-turning, modeling, moulding and pressing, and painting.”[13] The men who filled these positions remain unidentified, but insights into their abilities can be gained by analyzing the physical characteristics of the factory wares.

The analysis is helped by Young’s discussion of the hierarchy of the skilled craftsmen in the eighteenth-century English porcelain industry who were responsible for the production of the various vessel forms and sculptural figures. At the top of this hierarchy were the modelers, whose skills are primarily as artist-sculptor. Beyond the commission of busts and other public sculptures, these individuals would be asked to create specific models for porcelain factories. The second tier is composed of those modelers trained specifically in the European porcelain workshops who subsequently were employed by English firms or who supplied models and molds as independent commissions. The third tier was the London-trained figure makers who provided models to English porcelain works. The fourth tier was the modelers and mold makers whose training was firsthand experience within English porcelain manufactories. The fifth, and lowest, tier was composed of skilled workers, known as “repairers,” whose role was to assemble the various ceramic casts taken from molds into a finished form.

In light of these categories, we chose to replicate the complex Bonnin and Morris pickle stand in order to better understand the expertise necessary to produce it. As with any industrial enterprise, the key to success requires both know-how and the proper materials. The American China Manufactory was short-lived, probably producing porcelain for little more than two years, yet the products that have survived reflect both a high order of expertise and a successful soft-paste porcelain body.

The primary goal of our project was to understand the unique aesthetic design of the pickle stand and to document the basic process of designing and constructing it; an exact reproduction was neither the intent nor even a desired outcome. The process was limited to the methods used in molding, forming, and assembling. No attempts were made to reconstitute an accurate porcelain clay body. A commercially available porcelain clay was selected for the project. The finished models were fired to bisque temperature. Replicating the blue painted brushwork was not part of our effort, although such a study might prove useful to identify an individual decorator or decorators. In addition, we have not yet devised a suitable glaze for a final gloss firing.

Making a Bonnin and Morris Pickle Stand

The first step of this replication process was the visual examination of the existing Bonnin and Morris pickle stands. We were fortunate to be able to physically handle most of them at least once, but due to their fragile and precious condition we subsequently had to rely on detailed photographic images. For convenience, a circa 1765 Bow pickle stand was used as a hands-on study model. The critical dimensions of an original Bonnin and Morris example were noted on working photographs. Archaeological fragments housed at the Philadelphia Museum of Art were also examined.

The tripartite pickle stand, as produced by both the American China Manufactory and Bow, has three major components: the base, consisting of three open shell dishes or cups; a central vertical stalk; and an open top cup. This vocabulary is virtually identical in both the Philadelphia example and the Bow examples. The critical difference lies with the three open shells and, to a lesser extent, the top cup. The Bow and virtually all other English porcelain examples are molded from hand-sculpted models representing generalized bivalve shells. In significant contrast, the Bonnin and Morris shell dishes are taken directly from real scallop shells, a detail that proved to be one of the most diagnostic elements of their pickle stands.[14]

While investigating the potential source of the shell used for the pickle stand, we encountered a fair amount of folklore from various Bonnin and Morris aficionados, including a claim that fossilized examples found in the Philadelphia area were the original inspiration. We also consulted with several natural history specialists, providing photographs of the cast shells in the pickle stand, but the responses were not uniform. As we had the benefit of hands-on examination, we ultimately determined that the most likely candidate for the shell was Pecten maximus (Great Scallop).[15] The range of Pecten maximus includes all of the British coastlines and from Norway to Spain.[16] The species was an important food source for, and clearly available to, eighteenth-century British and European inhabitants and to Americans as an import. Today these shells are marketed as Irish baking dishes and are used widely in the culinary industry to cook and serve seafood.

Once the scallop shell was identified, several samples were obtained from commercial suppliers. Our first examples were not large enough or deep enough but we later acquired a suitable specimen (fig. 6). Scallops are bivalves and have two distinct halves. Each shell valve is fan-shaped, with an “ear” on either side of its apex, and has 15–17 radiating ribs. The right valve is strongly convex, whereas the left valve is flat. The key morphological elements of the shell as it relates to identifying its use in the Bonnin and Morris pickle stand include its large size (4–6 inches) and the radiating ribs, which are rounded.

The next step was to make a plaster cast of this sample shell (fig. 7). A thick-walled casting form was raised on a throwing wheel to create a container for the casting process. The scallop shell was pushed into this form and coated with light oil to help resist the plaster. A plaster mixture was then slowly poured into the form while trying to avoid trapping air bubbles (fig. 8).

When the plaster was cured, the clay walls of the form were removed and the scallop shell was lifted from the plaster, producing the negative mold necessary for the slip casting process (fig. 9). It is essential that the newly cast plaster mold be dry before proceeding.

Once the mold was formed, experiments undertaken to see whether the originals had been press molded or slip cast suggested that the latter was employed by the Bonnin and Morris factory. Before the dry mold could be used for slip casting, however, a soft-clay wall was added to the hinge side of the mold to prevent the slip from running out of the mold; more important, it would provide a clean lip or edge to facilitate pouring off excess slip. The slip was then poured into the mold (fig. 10), filling the cavity (fig. 11). The mold was left undisturbed for several minutes while the porous plaster absorbed the water in the slip. The length of time the slip remains in the mold is critical to determining the final thickness of the resultant cast shell—the longer it sits, the thicker the resultant cast. When the slip is poured away, the very soft cast shell remains (fig. 12). The cast is allowed to dry to a leather-hard state before it is carefully removed from the mold (fig. 13). The mold can be used again, but it is most effective if allowed to dry between castings.

The casting exercise confirmed that this is how the original shells were created. Two characteristics in particular were significant: the telltale sign of how the shell’s interior contours follow the exterior forms, although this is less evident in the deepest part of the shell’s interior; and the ribbonlike shelf created by the casting found at the edge of the shell (see fig. 25). We did attempt press molding some scallop shells, but none of the distinctive attributes displayed by the originals was easily achieved without contrivance; this was not true with slip casting, which produced all of the necessary characteristics seen in the original.

The two other major structural components were prepared using plaster molding techniques (figs. 14, 15). The top cup on the stand is a design artifice but simulates the ribbed nature of a scallop shell. Circular in plan and shaped like a shallow teabowl, the cup provides the most symmetrical element of the entire composition. The Bonnin and Morris top cup is very distinctive and finely proportioned, having thirty-one radiating ribs. The top cup on the Bow example, in contrast, has only seventeen (see fig. 36). The original model for the cup may have been fashioned from a wood block that had been turned on a lathe and subsequently carved. For our purposes it was expedient to use a model that was thrown thickly in porcelain clay, then hand-carved and sculpted to the specifications of the original. This model was used to create a plaster mold. The mold was centered on the wheel and a ball of wet clay was thrown into it to create the cup form. This technique permitted the interior of the cup to be smoothed while the mold rotated on the wheel, as per the original. The plaster mold helped to remove moisture from this thrown cup, causing it to pop out of the mold in a relatively firm state.

Another plaster mold was needed to create the upright stalk, the central pillar of the architectural arrangement. This was best accomplished with a cylindrical, two-piece press mold. Flanges were integrated into the top and bottom to assist in connecting both the three bottom dishes and the cup.

The mass of shell encrustations on the Bonnin and Morris pickle stand and most English models is, at first glance, reminiscent of the chaotic agglomerations found in marine life. Yet close inspection allows some perspective on how the random effect was created.

Both the Bonnin and Morris as well as nearly all English models took molds from naturally occurring mollusks to create these smaller shells. The primary shell used is the Cerastoderma edule (Common Cockle), still widely fished in Great Britain and France, and clusters of these shells are found in shallow bays throughout the region. Another smaller shell used on the Bonnin and Morris stand is that of the Patella vulgate (Common Limpet).[17] A few, even smaller snail-like shells, very broadly classified in the order Mesogastropoda, are interspersed on the stalk.[18] We used shells that had the right shape and proportion, even if they were not an exact species match.

As with the large scallop shell, molds of these smaller shells had to be created (fig. 16), and a more direct technique for taking casts of them was found to be quite effective. A slab of porcelain clay was prepared approximately one inch in thickness; the sample shells were lightly oiled, slowly pressed into the clay, then carefully removed, resulting in clear impressions. An assortment of sizes and shapes can be obtained by pressing into a single slab of clay. The slabs were dried slowly, to avoid cracking and distortion, and then fired to bisque temperature. Once fired, the molds were ready for use.

Taking casts from these simple press molds began with preparing a small ball of clay and pressing it into the cavity, making sure the mold was covered (fig. 17). These molds were very efficient due to the quick absorption of moisture by the bisque mold, and dozens of casts could be made in a matter of minutes (fig. 18). This exercise alone helps clarify how these delicate and realistic shells could be created with a modicum of artistic skill.

Another of the natural components of the Bonnin and Morris stand was the inclusion of tube worms in the composition. These calcareous tube worms, generally identified as belonging to the Serpulida family, are also marine organisms that profusely encrust shell beds, rocks, and pilings.[19] The facsimiles of these tubes were formed by hand, taking a small clay coil and opening both ends (fig. 19).

As demonstrated thus far, preparation of the individual components of the pickle stand appears to have been a straightforward but time-consuming task. All of the elements had to be kept in a damp, leather-hard state for the assembly phase. While the conglomeration of the marine elements appears random, a fairly specific hierarchy of the shell embellishments was used. To better understand this order, the components were laid out in a schematic fashion as a working map of the construction (figs. 20, 21).

The casts of the three scallop shells, which retained the ears or wings seen in the surviving pickle dish from the American China Manufactory, were the first elements to be joined (see Plate 13). For the construction of the stand, the ears of the scallops were first cut away to allow a tight fit to the tripartite arrangement (fig. 22). The shells were then assembled in the proper orientation while upside down on the work surface. Coils of the porcelain clay were rolled and then shaped into triangular strips or fillets, the best shape to fill the expected gap between the aligned shells. The pointed side of the strip was lightly tapped or pounced into the crevices between the shells, following their contours, and bonding them together (fig. 23). These were later stippled with a metal tool to simulate fossil corral, which also aids adhesion (fig. 24).

After the shells were attached (working from the bottom up), the base was righted and the broad ribbonlike edge that develops in the casting process was tapered and smoothed with a wet sponge (fig. 25). The upper crevices between the scallop shells were then filled with clay strips, and the cast stalk was centered in the composition. The flange on the cylindrical stalk facilitated the attachment of this piece to the intersection of three scallop shells (fig. 26). The top cup was placed on the stalk and secured with an application of wet slip. The upper flange of the stalk was molded into the base of the top cup. The stalk was stippled at this stage, simulating fossilized coral (fig. 27). The imitation of fossilized coral is characteristic of a number of other English prototypes, particularly the Bow model we used as a guide. All of the stippling is done when the wet clay has firmed to leather hardness, so that surface resistance prevents the point of the tool from sinking in too deeply; it also helps to prevent distortion of the surface from the repeated jabbing of the tool.

The addition of the marine incrustations begins with wrapping the stalk with a ribbon of clay representing a strand of sea grass or possibly kelp (fig. 28). This strand not only added an aesthetic element but also helped obscure the points of attachment of the top cup and the bottom shells with the stalk. Small cast snails were later attached to this strand, furthering the illusion of an active marine environment.

The complicated task of creating the clusters of cockle and limpet shells began next (fig. 29). These masses of shells have both an aesthetic and structural purpose—to camouflage the joins of the stand and to serve as connective support. The individual shell casts were arranged in three groupings around the stalk, and the shells were laid on in a specific pattern to best approximate the spacing on the originals. Drops of porcelain slip were used to cement the points of attachment. Pairs of cockle shells were assembled to represent living mollusks in the groupings of shells interspersed with tube worms (fig. 30). Small snails and tube worms were placed around the stalk (fig. 31). A needle tool helped with attaching these tiny, delicate components (fig. 32).

The final stage in the assembly was the attachment of the cone-shaped feet to the bottom of the stand (figs. 33, 34). The feet were shaped by hand, although some sort of simple mold may have been used in the original process. Both the stand and the feet had to be fairly dry before the stand could be turned upside down to attach the feet, and, in turn, the feet had to be sturdy enough to support the weight of the finished piece when it was righted (fig. 35).

The exploration of the molding and assembly of a Bonnin and Morris pickle stand was now complete. Three stands had been assembled to leather-hard state and one was bisque fired (fig. 36). While future research may consider the decorating and glazing techniques, the reconstruction of these stands successfully illustrates the basic technologies used by the Bonnin and Morris workforce.

Assessment of the Reconstruction Project

From the outset, although we had some questions about the construction techniques involved in producing a Bonnin and Morris pickle stand, the replication project was largely inductive. In other words, it was hoped that the process itself would raise questions about the technology behind the object’s creation that we might not have otherwise asked.

The step-by-step examination revealed what skills were needed to make the required molds and to obtain the suitable casts for the many components of the pickle stand. It became apparent that the men who arrived in Philadelphia from England and went to work at the American China Manufactory in 1770 had to create the molds for the pickle stand and probably the entire factory’s vessel forms as well. Since both the top cup and the bottom shells do not exist as English prototypes, these workmen did not bring working molds with them. This suggests, using Hilary Young’s hierarchy, that a fourth-tier modeler or mold maker with firsthand training in an English porcelain manufactory could have been among the Bonnin and Morris workmen—or, at the very least, that the fifth tier was represented by one or more skilled repairers.

It is not clear why Bonnin and Morris chose to use naturally occurring scallop shells for the tripartite base. As Young has pointed out, even though the English porcelain industry was characterized by imitation of foreign prototypes, the “very act of copying often imparted the English reproductions with an aesthetic character all their own.”[20] In extending this assertion to the Philadelphia products, the copying of an English prototype—most obviously the Bow example—produced a pickle stand with a new aesthetic standard, particularly with the inclusion of the cast Pecten maximus shells.

Interest in marine shells ran high among the eighteenth-century Anglo-American cognoscenti. Glenn Adamson has suggested that the creation and design of the pickle stand may have been, in part, a response to the Philadelphia scientific community’s excessive fascination with natural history. The use of life casts does lend the Bonnin and Morris examples the appearance of being more of a “scientific-quality model of marine life” than those created by the Bow factory with its imitation of the large bivalve shells.[21] This very fact may supersede the elevated alchemical hype of porcelain manufacture that by 1770 probably did not merit much consideration—making porcelain was no longer a mystery to those in the ceramic industry. Or, as Adamson suggests, perhaps it is the juxtaposition of its realistic composition with the artifice of the porcelain that gives the Bonnin and Morris pickle stands such a curious aura.[22]

So, was the inclusion of the cast scallop shells a design decision or simply the expedient means to an end? Most of the similar English prototypes used hand-sculpted approximations of large bivalves for the open cups. Perhaps the Bonnin and Morris workforce did not have that level of sculpting ability, in which case taking molds from readily available materials would have been the best way to proceed.

The reconstruction of a Bonnin and Morris pickle stand also suggests that much can be learned about the technologies behind the production of their other forms. Most important, a study of this kind should be initiated to investigate the molded sauceboats. Did the workmen take molds directly from existing English examples and rework them, or were the models unique and created at the factory? Many questions remain to be explored through future research.

Regardless of the ultimate answers to these questions, the Bonnin and Morris pickle stand is unquestionably an unmitigated success story in the history of American ceramics. The surviving six examples should be valued for their place not only in American ceramic history but in the general chronicle of eighteenth-century porcelain design. They reflect state-of-the-art craftsmanship, a thorough understanding of porcelain chemistry, and a magnificent aesthetic that is uniquely Philadelphian.

Graham Hood, Bonnin and Morris of Philadelphia: The First American Porcelain Manufactory, 1770–1772 (Chapel Hill: University of North Carolina Press, 1972). See also J. Victor Owen, “Compositional and Mineralogical Distinctions between Bonnin and Morris (Philadelphia, 1770–1772) Phosphatic Porcelain and Its Contemporarily British Counterparts,” Geoarchaeology 16, no. 7 (2001): 785–802.

Hilary Young, English Porcelain, 1745–95: Its Makers, Design, Marketing and Consumption (London: V&A Publications, 1999); Julie Emerson, Jennifer Chen, and Mimi Gardner Gates, Porcelain Stories: From China to Europe (Seattle: Seattle Art Museum, 2000).

Simeon Shaw, History of Staffordshire Potteries (Hanley, 1829). For a recent example, see David Barker, “Bits and Bobs: The Development of Kiln Furniture in the 18th-Century Staffordshire Pottery Industry,” English Ceramic Circle Transactions 16, pt. 3 (1998): 318–40. Michelle Erickson and Robert Hunter, “Dots, Dashes, and Squiggles: Early English Slipware Technology,” in Ceramics in America, edited by Robert Hunter (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 2001), pp. 94–114; Michelle Erickson and Robert Hunter, “Swirls and Whirls: English Agateware Technology,” in Ceramics in America, edited by Robert Hunter (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 2003), pp. 87–110.

An excellent account of the material retrieved from the Bow factory site is provided by David Redstone, “Finds and Excavations on the Bow Factory Site 1867–1969, Part II,” English Ceramic Circle Transactions 16, pt. 3 (1998): 82–108. More recent salvage excavations by the Museum of London have retrieved a vast amount of material, including fragments of plaster molds, that is awaiting analysis; personal communication, Jacqui Pearce, Museum of London, Specialist Services.

Emerson, Chen, and Gates, Porcelain Stories.

Leonard N. Amico, Bernard Palissy: In Search of Earthly Paradise (Paris: Flammarion, 1996).

Beth Carver Wees, “Silver in the Clark Art Institute,” Antiques (October 1, 1997): 536–45.

Howard Coutts, The Art of Ceramics European Ceramic Design, 1500–1830 (New Haven: Yale University Press, 2001), p. 145.

John C. Austin, Chelsea Porcelain at Williamsburg (Williamsburg, Va.: Colonial Williamsburg Foundation, 1977), pp. 28–29.

The bill is reproduced as Appendix 7 of Hood’s book Bonnin and Morris, and appears in this volume on page 58. The original resides in the Cadwalader Collection, Historical Society of Pennsylvania, Philadelphia.

Ibid.

Young, English Porcelain, p. 86.

Alfred Coxe Prime, comp., The Arts and Crafts in Philadelphia, Maryland and South Carolina, 1721–1785: Gleanings from Newspapers ([Topsfield, Mass.]: Walpole Society, 1929), p. 114.

An exception might be a rare shell pickle stand produced at the Vauxhall porcelain factory. The Watney Collection of Fine Early English Porcelains, Part II, sale cat. (New York: Phillips Auction House, May 10, 2000), lot 738, p. 138.

We are indebted to Dr. William DePaul at the Virginia Institute of Marine Science, College of William and Mary, for his comments and assistance.

Peter Hayward, Tony Nelson-Smith, and Chris Shields, Collins Pocket Guide: Sea Shore and Britain & Europe (London: HarperCollins, 1996).

Ibid., p. 180.

Ibid., p. 186.

Ibid., p. 112.

Young, English Porcelain, p. 94.

Glenn Adamson, “The American Arcanum: Porcelain and the Alchemical Tradition,” pp. 94–119 in this volume.

Ibid.