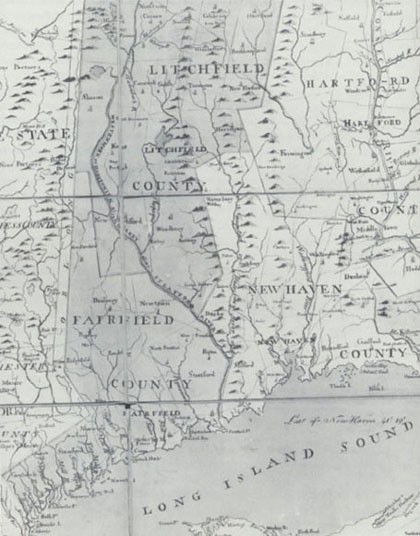

Bernard Romans, map of Connecticut, 1777. (Courtesy, Beinecke Library, Yale University.)

Bottom half of a chest-on-chest attributed to Brewster Dayton, Stratford, Connecticut, 1770-1790. Cherry with yellow poplar and oak. H. 44 1/4", W. 40", D. 20". (Courtesy, Middlesex County Historical Society; photo, Edward S. Cooke Jr.)

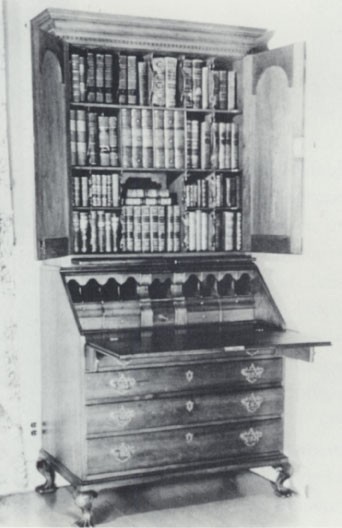

Desk-and-bookcase, probably by Ebenezer Hubbell, Stratford, Connecticut, 1760-1780. Cherry with yellow poplar, white pine, yellow pine, and butternut. H. 93 1/4", W. 40", D. 23 1/4". (Courtesy, The Connecticut Historical Society, Hartford, Connecticut.)

Chest of drawers, Litchfield, Connecticut, 1780–1800. Cherry with white pine. H. 34", W. 35 5/8", D. 19 1/2". (Courtesy, Mattatuck Museum.)

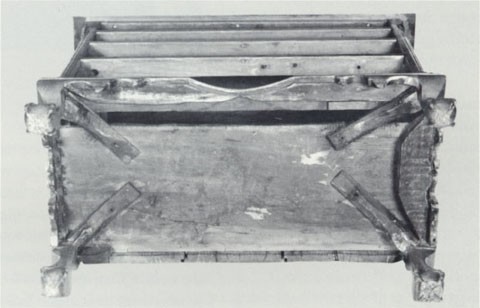

Detail of the bottom of the chest illustrated in fig. 4.

Chest of drawers, Litchfield, Connecticut, 1780–1800. Cherry with white pine and yellow poplar. H. 32 3/8", W. 36 3/8", D. 18 3/4". (Courtesy, Mattatuck Museum.)

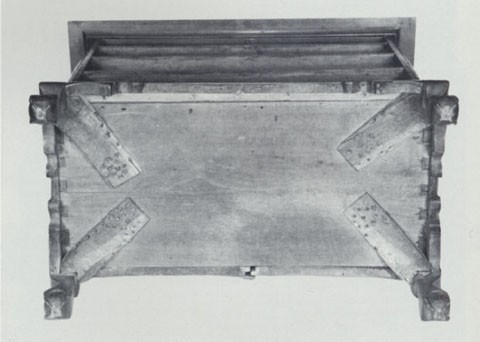

Detail of the bottom of the chest illustrated in fig. 6.

Chest of drawers signed by Bates How, northwestern Connecticut, 1795. Cherry with white pine. H. 38 1/2", W. 39 3/4", D. 17 1/4". (Courtesy, Yale University Art Gallery, Mabel Brady Garvan Collection.)

Chest-on-chest signed by Reuben Beeman, Kent, Connecticut, 1795–1805. Cherry with white pine. H. 88 1/2", W. 43". (Courtesy, Christie’s.)

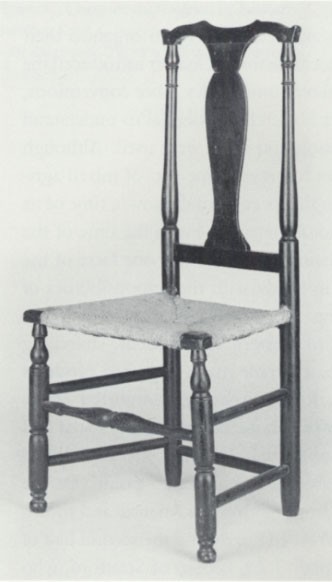

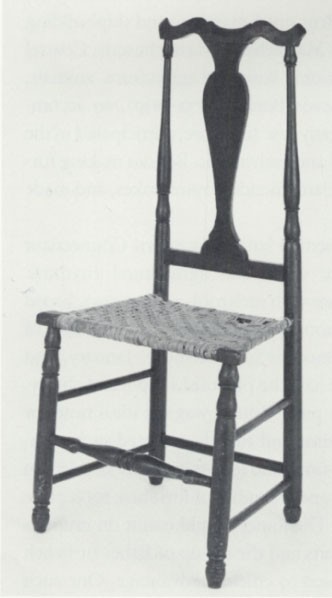

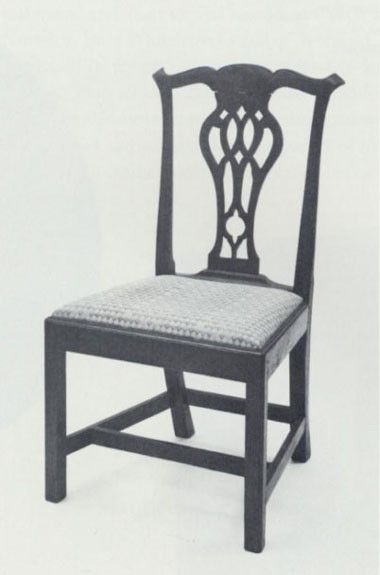

Fiddleback chair, Stratford, Connecticut, 1760–1800. Maple, yellow poplar, and ash. H. 38 5/8", W. 19", D. 14". (Courtesy, Discovery Museum; photo, Gavin Ashworth.)

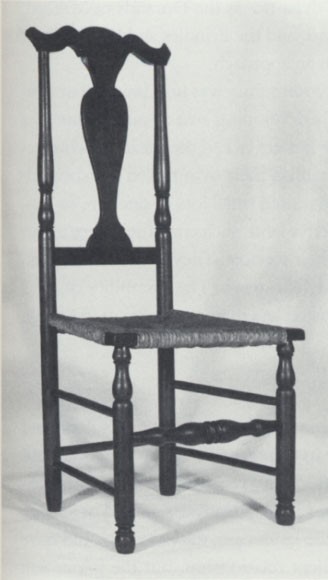

Fiddleback chair, Newtown, Connecticut, 1760–1800. Maple, yellow poplar, and ash. H. 40 1/8", W. 19 1/2", D. 14". (Private collection; photo, Gavin Ashworth.)

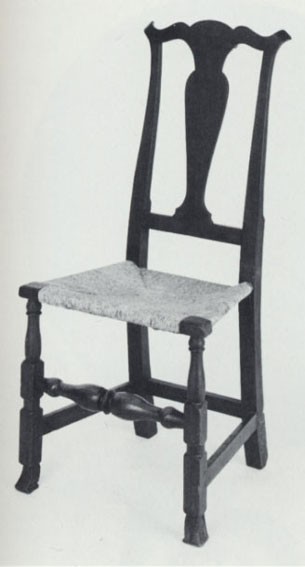

Fiddleback chair, Woodbury, Connecticut, 1760–1800. Maple, yellow poplar, and ash. H. 42 1/8", W. 20 1/2", D. 14". (Courtesy, New Haven Colony Historical Society.)

Chest of drawers signed by Brewster Dayton, Stratford, Connecticut, 1784. Cherry with sycamore, yellow poplar, and white pine. H. 86 1/2", W. 39 3/4", D. 20 3/8". (Courtesy, Winterthur Museum.)

Chest of drawers signed by Brewster Dayton, Stratford, Connecticut, 1784. Cherry with yellow poplar. H. 87", W. 39 3/4", D. 20 1/8". (Private collection; photo, Edward S. Cooke Jr.)

Married chest of drawers (top probably by Brewster Dayton; bottom probably by Ebenezer Hubbell), Stratford, Connecticut, 1770–1790. Top: cherry with yellow poplar and white pine; bottom: walnut with cherry and white pine. H. 72 1/4", W. 40 1/2", D. 20 1/8". (Private collection; photo, Edward S. Cooke Jr.) All of the drawers in the lower section are replacements.

Desk, probably by Ebenezer Hubbell, Stratford, Connecticut, 1760–1780. Cherry with white pine and yellow poplar. H. 42 5/8", W. 36 3/16", D. 21 3/4". (Courtesy, Discovery Museum; photo, Gavin Ashworth.)

Desk, probably by Ebenezer Hubbell, Stratford, Connecticut, 1760–1780. Mahogany with white pine and yellow poplar. H. 49 1/2", W. 39 3/4", D. 20". (Private collection; photo, Di Cambio Studio.)

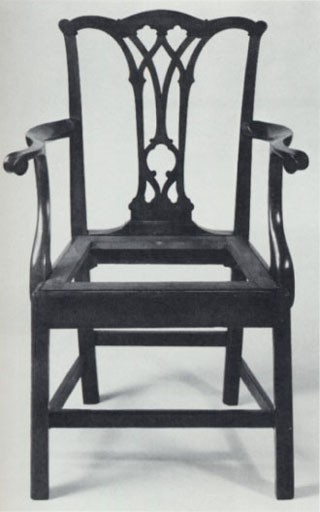

Joiner’s chair, possibly by Ebenezer Hubbell, Stratford, Connecticut, 1770–1790. Cherry, yellow poplar, and ash. H. 39 3/4", W. 22", D. 17 1/8". (Courtesy, Barry G. Freeman.)

Chest of drawers signed by Silas Butler, Woodbury, Connecticut, 1755. Cherry with white pine. H. 86", W. 40", D. 20". (Courtesy, Wadsworth Atheneum.)

Chest of drawers, Woodbury, Connecticut, 1760–1780. Cherry with red oak, white pine, and yellow poplar. H. 80", W. 39 5/8", D. 19 5/8". (Courtesy, The New Haven Colony Historical Society.)

Great round-top chair, Woodbury, Connecticut, 1750–1770. Maple, yellow poplar, and ash. H. 42 1/4", W. 22 1/2", D. 15". (Courtesy, First Congregational Church, Woodbury; photo, Edward S. Cooke Jr.)

Crooked-back chair, Woodbury, Connecticut, 1780–1800. Cherry, yellow poplar, and ash. H. 41 1/2", W. 20 1/8", D. 13 3/4". (Private collection; photo, Gavin Ashworth.)

Joiner’s chair, Woodbury, Connecticut, 1780–1800. Cherry, yellow poplar, and ash. H. 38", W. 19 7/8", D. 15 5/8". (Private collection; photo, Cortes and Company.)

Tea table, Woodbury, Connecticut, 1780–1800. Cherry. H. 27", top diam.: 33". (Private collection, photo, Gavin Ashworth.)

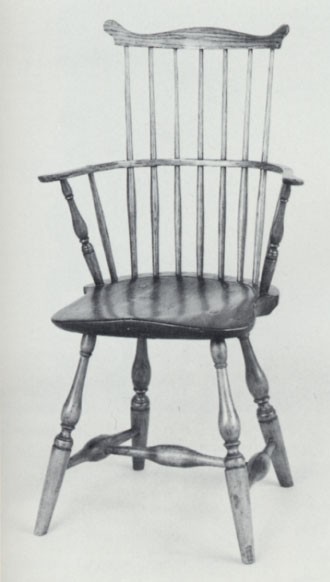

High-back Windsor armchair, probably by Nicholas Jebine, Woodbury, Connecticut, 1790–1810. Maple, white pine, and red oak. H. 36 1/4", W. 16 1/4", D. 16 9/16". (Courtesy, Yale University Art Gallery, Mabel Brady Garvan Collection.)

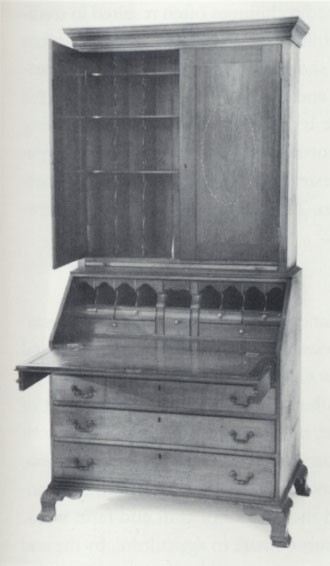

Desk-and-bookcase, Woodbury, Connecticut, 1780–1800. Cherry with white pine and yellow poplar. H. 84", W. 38", D. 20 3/4". (Private collection; photo, Edward S. Cooke Jr.)

Chest of drawers, Woodbury, Connecticut, 1780–1800. Cherry with red oak. H. 33 1/4", W. 34 3/8", D. 20 1/2". (Courtesy, Hartford Steam Boiler Inspection and Insurance Company; photo, Gavin Ashworth.)

Chest of drawers, Woodbury, Connecticut, 1790–1810. Cherry with yellow poplar. H. 37", W. 44", D. 18 3/4". (Private collection; photo, Edward S. Cooke Jr.)

Desk-and-bookcase, Woodbury, Connecticut, 1780–1800. Cherry with yellow poplar and red oak. Dimensions not recorded. (Courtesy, Kenneth Hammit.)

Desk-and-bookcase, Woodbury, Connecticut, 1780–1800. Cherry with yellow poplar, white pine, and ash. H. 85 5/8", W. 39 3/4", D. 22". (Private collection; photo, Cortes and Company.)

Chest of drawers, Woodbury, Connecticut, 1780–1800. Cherry with red oak, yellow poplar, and white pine. H. 90", W. 44", D. 22 3/4". (Courtesy, Colonial Williamsburg Foundation.)

Chest-on-chest, Woodbury, Connecticut, 1780–1800. Cherry with yellow poplar and red oak. H. 82 1/2", W. 40 3/4", D. 19 3/4". (Private collection; photo, Edward S. Cooke Jr.)

Samuel Goodrich, the author of the many Peter Parley stories published in the second quarter of the nineteenth century, grew up in the southwestern Connecticut hill town of Ridgefield during the late-eighteenth and early-nineteenth centuries. Reflecting on his childhood home several decades later, Goodrich commented upon the local agrarian economy, the role of the yeoman-craftsman, and the “simple character” of the domestic furnishings:

Nearly all the inhabitants of Ridgefield were farmers, with the few mechanics that were necessary to carry on society in a somewhat primeval state. Even the person not professionally devoted to agriculture had each his own farm, or at least his garden and home lot, with his pigs, poultry, and cattle. . . . The household, as well as political, economy of those days lay in this,—that every family lived as much as possible within itself.[1]

Among those not professionally devoted to farming were blacksmith David Olmstead and joiner, or cabinetmaker, Elisha Hawley. These craftsmen served both economic and cultural roles. Their “articles of use” were important items of exchange in the specie-poor economy. On a deeper level, the artifacts they produced “expressly” for their fellow townspeople became cherished possessions. Goodrich fondly recalled the identity of the local craftsmen who helped create his family’s domestic environment.[2]

Although Goodrich lamented the primitive material state of his youth, particularly in contrast to the abundant domestic refinement of his later years, his remarks on the local economy point out the importance of artisans within an interdependent network of independent households. In western Connecticut (fig. 1) between 1750 and 1800, a truly mixed agricultural economy incorporated grains, animals, and crafts. It is therefore important to examine craftsmen and the context of their work within this multi-faceted economy. I use the term social economy to describe this context because it refers to a particularized web of relations and activities that preceded a capitalist political economy. The products of local craftsmen emanated from and responded to a specific set of social relationships. The term social economy recognizes the importance of craftwork to the decisions of a household on the allocation of resources for production and exchange. It was a time, as Michael Foucoult suggests, in which the value of work and objects was gauged more by social standards than by monetary ones. In such an integrated community, skill took on meanings far different from today’s notions of quality.[3]

The creation and use of objects are integral parts of a dynamic social process, not just static events or ends unto themselves. Artifacts evolve and gain meaning out of cultural values and social relationships and, in turn, shape and maintain cultural values and social relationships. During a period of limited advertising and uneven, fluctuating exposure to several fashion systems, the local arena was where the meanings of goods were selected, adapted, invested, or divested. Furniture, in particular, serves as a signifier: it can provide functional enjoyment or comfort for a person or household; it can indicate surplus exchange power; it can manifest memories of past experiences and social relationships; it can unify or differentiate peoples; it can embody abstract ideals such as accomplishment or achievement, social power, or stability; and it can serve as an owner’s legacy to be passed on into the future.[4]

Joiners, who lived in every town and whose products combined enduring utility and changing fashion, worked at the interface of traditional household or community values and external market forces. During the last half of the eighteenth century, joiners in western Connecticut were linked by a common technical tradition. The largest shops consisted of two benches in a 300 to 400 square-foot area and a work force of six. Most shops tended to be slightly smaller, with one bench and two or three joiners. Probate inventories from the region also reveal the similarities of joiners’ tools: the major distinction of the larger shops is a greater number of certain tools, like molding planes, rather than the type of tool. A basic and effective chest of tools for preparing, assembling, and finishing furniture seems to have been accessible to most joiners with their own shops. Artifactual evidence from the region’s furniture reveals that joiners could draw upon a number of techniques to construct furniture—mortise-and-tenons, post-and-rungs, dovetails, or nails—or to decorate furniture—sawn profiles, molding, turned ornament, carving, or inlay. Often the craftsman combined a variety of techniques on the same piece of furniture. The size of the shop and workforce, the relative low cost of tools and basic materials, and the variety of techniques gave the preindustrial joiner of the region a great deal of flexibility during this period of “low technology” craft production. Drawing upon a broad technical repertoire and a shop tradition that stressed economical use of human skill, the joiner worked skillfully and efficiently to create a wide range of furniture. He could respond quickly to a client’s demands or to new fashion without drastic retooling.[5]

Despite the joiners’ use of similar tools, technologies, and work spaces, considerable variety prevailed among the furniture made and owned in western Connecticut from 1750 to 1800. Not only are there differences in furniture forms and decoration between towns, but also within towns. We thus need to identify what restricted or encouraged the artisan’s choice of form, technique, or decoration. The specific context in which a joiner worked is crucial to any understanding of these selections and adaptations. His web of social and economic relations determined his composition, tool selection, techniques, work rhythms, levels of production, and the look of the final product. The craftsman’s choices were grounded within a very specific set of learning experiences, economic systems, and social norms and obligations. By focusing attention on how the joiner learned his trade and then refined or expanded his skills and attitudes, we can begin to analyze the workings of the social economy of the region.

Acquisition of Skills

Apprenticeship, a system that clarifies especially well the social basis for the joiner’s trade during the preindustrial period, was the primary method for learning the craft. In the eighteenth century, apprenticeship differed significantly from its modern or contemporary form. Today, a person voluntarily enters into an apprenticeship with a company to learn a specific aspect of the trade. The company pays the apprentice a minimal wage during the learning process and defines all relationships between company and apprentice by wage rates and working hours. The company essentially cares only about the apprentice’s performance on the job and how quickly he will pay back the investment. Room, board, and life outside of work are the apprentice’s own responsibilities.[6]

Preindustrial apprenticeship was fundamentally a social contract in which mutual obligations and expectations bound the two parties. The young lad followed certain prescribed rules of living in return for instruction in a trade. Like the son of a farmer, the apprentice was willing to give up certain personal freedoms and to perform certain tasks for a paternal figure with little direct recompense, because he expected to become a master himself. The master willingly taught the youth and took him into his household, because the apprentice’s commitment permitted the master to increase the variety and scale of operations and to maximize opportunities during his peak years of physical activity. Apprenticeship ensured the availability of extra labor for preparatory tasks such as sawing and dressing stock as well as the ability to undertake larger, more logistically complicated tasks such as fabricating large case furniture, paneling interiors, or hauling boards. In addition, young apprentices even served as a form of human credit. During slack periods in his own shop, the master “rented out” his apprentices to others in the community for simple woodworking tasks or even for agricultural labor. In such a case, the youth was not working on his own time but rather as a member of the master’s household. The apprentice’s labor thus built up indebtedness within the community that the master could draw on as need arose.

Even apprenticeship selection was based upon the social network; a young craftsman in his twenties took on the sons of neighbors or relatives. A joiner in his thirties turned to his own adolescent sons for apprentices. Those with daughters but no sons often arranged for a daughter to marry an apprentice or a member of another shop, thereby consolidating or controlling the trade for the next generation. Once the elder craftsman had set his own children up as independent adults, he had less interest in his production and earning power. At this later point in his career, the joiner became an individual craftsman, helping out in local shops when needed or undertaking light work or repair work.[7]

The apprenticeship agreement between Lazarus Prindle and Joseph Peck Jr., both of Newtown, sheds light upon this training process in a time when life and work were interwoven and work arranged along household lines. On June 5, 1793, Peck, then fifteen years old and with his father as witness, bound himself to Prindle for a two-year training period. In return for instruction, Peck promised to serve faithfully, keep his master’s secrets, waste none of his master’s goods, avoid unexcused absences, and obey his master’s lawful commands. In addition, Peck pledged not to commit fornication, to contract matrimony, to play at dice or other illegal games, to haunt taverns or playhouses, nor to buy or sell anything on his own during the term of his apprenticeship. In short, Peck completely resigned himself to Prindle’s authority.

For his part, Prindle, then thirty years old and without a son ready to apprentice, swore to teach and instruct the apprentice in the trade and mystery of a joiner. Furthermore, Prindle provided Peck with lodging, food, and washing by treating him as a surrogate son within the household. Upon the completion of his training, Peck would receive a good suit of clothes and take his place as a productive, good-standing member of the community.[8]

The “art, trade & mystery” of the joiner’s craft encompassed a wide range of attitudes, responsibilities, and activities. In an era before differentiation and specialization drew lines of distinction between design, workmanship, decoration, and marketing, the rural joiner oversaw and participated in the entire furniture-making process from conception through sale. The apprentice acquired these values and skills through a process that combined observation and imitation. Due to the casual interaction that took place in the small shop, the boy could see the decisions, actions, and results of the master or any other craftsmen who worked in that shop. In this manner, the apprentice internalized his master’s approaches and techniques. Less consciously, the apprentice also adopted certain attitudes about working wood. From a broad range of possibilities, the apprentice therefore learned and practiced the solutions favored and used by his master. In a time of human power and relatively low technology, a reliance on internalized solutions to structural problems, systematic and habitual motions, and familiar sequences helped to ensure efficient, satisfactory work. This workmanship of habit made craftwork economically viable. As a result, reflexive actions acquired and developed during training became an integral part of the joiner’s chest of tools. These conventions serve as diagnostic features that help group surviving furniture and identify it as the work of a particular shop tradition.[9]

A joiner’s later experiences supplemented, but never totally subsumed, the basic technical foundation acquired during his time as an apprentice. His performance, however, was not totally confined to mere replication of his master’s work; rather, he worked within a dynamic tradition of furniture making. He selectively gathered ideas about new techniques or approaches from the products of other shops in the same town or nearby, or from observations made during travel, the challenge of replicating imported furniture, meeting the new demands of a client, or repairing a piece of furniture made in another shop.[10] These new ideas, inevitable within a New England society far more mobile than has been perceived, were grafted onto existing structural habits or filtered through local working conventions.

In Stratford, for example, two shops dominated the local furniture market: that of Brewster Dayton and that of the Hubbell family. Dayton (working in Stratford ca. 1762–1796) was born across Long Island Sound in Brookhaven, New York, and apprenticed with an English-trained immigrant joiner in Stratford. His early experiences exposed him to the Anglo-Dutch work of Long Island and the vernacular Georgian work of his master. Ebenezer Hubbell (1726–1812), the master of the Hubbell shop during the last half of the eighteenth century, probably trained with his father Josiah, a joiner who helped build the side galleries for the town’s meetinghouse in 1715. His training thus took place entirely within Stratford.[11]

Case furniture documented or attributed to the Dayton and Hubbell shops reveals a specific set of Stratford features: carved feet with square pads, central toes flanked by two smaller toes on each side, and a tightly curved crooked leg; deeply carved shells in the lower drawers of desks and chests; blocks of wood nailed to the inside surface of these drawer fronts to provide extra depth for the shell carving; and extensive use of wooden trunnels (pegs) rather than iron nails to secure drawer bottoms, moldings, and drawer supports. However, the work of each shop is distinctive for its individual workmanship and forms. Slight differences in decorative work also distinguish the two shops: Dayton’s carved feet feature a central spade-shaped toe and are blockier than Hubbell’s more modeled feet, Dayton’s legs are slightly taller and therefore less sinuous, his shells are rather flat with simple ribs whereas Hubbell’s are deeper with more undulating ribs, and Dayton’s base moldings tend to be thicker than the thinner, more complex cymas by Hubbell (figs. 2, 3). Dayton also developed certain conventions for his construction: he often smoothed the inside surfaces of a carcass side with a toothing plane, added a butterfly key to strengthen the glued butt joint of a carcass side consisting of two boards, and chamfered the top edges of his drawer sides and backs. None of these features are found on furniture from the Hubbell shop. The similarities and differences suggest the way in which contemporaries in the same town could draw from different training to develop a similar language with distinct dialects.[12]

A similar relationship is evident in the work of two as yet unidentified shops in the Litchfield area (figs. 4-7). Case furniture from these shops is linked by very idiosyncratic base construction whereby diagonal braces are tenoned into the inner surface of the legs and nailed along the bottom of the carcass. Both shops also feature unusually graduated drawers and fashionable decoration such as ball-and-claw feet, fluting or quarter columns on the front corners, or extensive carving. Yet there are distinct differences in the work of the two shops: one features longer braces, drawer sides dovetailed to the drawer fronts and drawer backs dovetailed to the drawer sides, and more crisply executed carving (figs. 4, 5); the other features shorter braces, drawer sides dovetailed to the drawer fronts and backs, softer carving, and drawer bottoms with a rabbeted edge rather than a chamfered edge (figs. 6, 7). More finished joinery and the use of wooden pegs to secure the drawer bottoms to the drawer backs also distinguishes the latter shop. The differences cannot be explained by the role of a shared specialist but, rather, suggest the development of a shop tradition in the hands of an apprentice or the work of contemporaries who had similar training but employed different types of joiners in their respective shops.[13]

A similar relationship can be seen in the work of Bates How of Canaan (fig. 8) and Reuben Beeman of Kent (fig. 9). Signed work by these joiners reveals many similarities: squat, carved ball-and-claw feet, extensive reliance on rope carving along base moldings and quarter columns, similar dovetailing of drawers, and backboards dovetailed to the back edges of the carcass sides. In spite of these shared idiosyncracies, there are noticeable differences between the shops. How’s signed chest features extensive use of screws to attach the moldings and quarter columns and an abundance of knotty, second-grade white pine boards. Beeman’s work lacks the reliance on screws and scrap pine and has a distinctive drawer detail: the sides taper toward the upper edge, thereby providing more material where the groove for the drawer bottoms is run. The differences between the How and Beeman shops suggest that craftsmen with different training responded in similar ways to the market in the hill towns of northwestern Connecticut.[14]

Rhythms of Work

Under apprenticeship, young joiners also learned how to organize their tasks and rhythms in accordance with local custom. A master introduced the boy to and subtly schooled him in local economic cycles, labor conventions, and sources of materials and credit. It is therefore essential to understand the particular context in which the tools and skills were used. Although most rural New England communities followed some sort of mixed agriculture, each economy varied based on the location of the town, time of its founding, size, social structure, and local materials. From the time of the earliest settlements, making chests, chairs, and tables was one facet of the agricultural cycle, and such work fit in neatly with the responsibilities of animal and grain husbandry and fishing.

In the older coastal communities of western Connecticut, stretching from Milford to Norwalk, limited coastal trade made imported products and materials available. Several Stratford storekeepers imported chairs made by Edward Larkin of Charlestown, Massachusetts, in the 1740s and 1750s, and the 1763 probate inventory of Captain Joseph Squier of Fairfield lists “6 Chairs boston make.” Inventory references also point out the increased availability of black walnut from the Middle Atlantic and southern regions and mahogany from the West Indies during the second half of the eighteenth century. Although Captain John Brooks of Stratford, who conducted trade with the Caribbean in the 1770s and 1780s, shipped six chairs made by Henry Beardslee to St. Croix in 1785, joiners’ work along the Long Island Sound was not as dependent upon maritime and shipbuilding rhythms as in maritime centers such as Marblehead, Massachusetts. Coastal trade was only a small part of an economy based on agriculture, animals, fishing, and small shop craftwork. Lewis Burritt (1772–1839), an accomplished joiner who made inlaid mahogany case furniture, participated in the varied Stratford economy of the 1790s and early 1800s. Besides making furniture, he hayed and pulled flax, made and mended oyster rakes, and made hat blocks and farming tools.[15]

Shop joiners in the more recently settled lands of western Connecticut organized their work in accordance with local agricultural rhythms. Widespread ownership of and experience with such tools as axes, saws, broad axes, and the like enabled the professional joiner to draw on a number of neighbors during the slack farming months of December, January, and February to fell, score, sled, split, and saw the plentiful supplies of cherry, maple, yellow poplar, oak, and white pine. Winter was the ideal time for such activity: farmers had more free time and eagerly accepted such occasional work, the wood cut best at that time, and logs were easily sledded on the snowy ground. Most preparation and assembly of furniture took place between harvest and spring planting. The joiners could count on uninterrupted time so that workmanship habits and the set-up of lathes or bench clamps in the small shops could be used to efficient advantage. One such discrete task was the production of great quantities of turned chair parts when the lathe was set up and slightly green wood was available. Case furniture could be produced throughout the year, but the work seems to have been concentrated between February and April and August and November. The first period followed the cutting of new wood and allowed the joiner to work the wood while slightly green, an advantage in turning and in some types of carving. The second period was when the clientele of farmers could calculate their harvest yield and therefore could gauge what they could afford to spend on furniture.[16]

The seasonal rhythms and local economies affected the types of furniture produced. Turned chairs were often produced and exported by urban craftsmen such as Edward Larkin but were also the ideal chair type to be produced in a rural-based, mixed agricultural community. There was always a market for chairs: they tended to suffer from abuse, were more affordable than more complicated furniture forms, possessed a fair amount of visual flair, and enjoyed greater demand due to changing social customs. In addition, they were easier to compose and make than case furniture. Due to practical considerations such as seat height and dimensions, the maker worked in a more circumscribed habitual manner when making chairs and tables than when making storage furniture. Standard dimensions provided the general parameters of design. Variations tended to be more in degree than kind, often concentrated in the appearance of the legs and back.

Rural joiners, who had the winter months free, could produce considerable quantities of turned chairs (figs. 10-12). They set up their lathes and turned parts efficiently and quickly by using a strike pole or marking stick to lay out the sections of turned elements and by maximizing the rhythm of their turning tools and lathe. They could also rive out quantities of wood for the slats or use a template to cut out the banisters and crest rails. It was thus possible and advantageous to stockpile certain parts such as stretchers, posts, and slats. Several jobs, such as bottoming and painting, could be subcontracted to others within the community. Joiners in western Connecticut often delegated such irregular work to young joiners just establishing themselves, older joiners in the twilight of their careers, or other members of the community. This subcontracting was not simply a means of reducing price but also of distributing work during the slack months, providing work for aging craftsmen, tightening the web of local exchange, and allowing the craftsman to organize his work and focus on furniture making during the winter months and other opportune times.[17]

Turned chair production was not a specialized task but rather standard output for a largely local market. Its production speed and the use of local labor and materials also enabled craftsmen to make case furniture in the winter months. Unlike chairs, case furniture was a more complex, open-ended product. Per capita ownership of such forms in comparison with the sets of chairs listed in accounts and inventories indicates there was relatively limited demand for large storage forms. Most households had several pieces of storage furniture, but there were consistently many more chairs and tables. There were also a number of options regarding form, size, and configuration of drawers and compartments. Finally, large drawered or doored furniture required more material and labor. Limited demand and the high cost of labor contributed to certain patterns of production in rural shops. A plentiful supply of butted and nailed chests—easily assembled from boards sawed at the local sawmill—has survived but so has a variety of joined case furniture such as high chests, dressing tables, and chests of drawers.[18]

The number of complex storage forms listed in the written documents and the evidence of the many surviving examples suggest that western Connecticut joiners employed a number of strategies to produce case furniture efficiently. Foremost was their reliance on local sawmills to provide boards in desired dimensions, thereby precluding the need to resaw or plane the lumber to usable thicknesses. In Newtown and Woodbury, surviving artifacts reveal the joiners’ use of blanks that required only slight planing before use. Some boards used for drawer linings or backboards still retain their water-powered saw marks. In Newtown, most cherry boards were sawn 3/4" thick, and yellow poplar and oak, 1/2" thick; in Woodbury, cherry tended to be 7/8" thick, yellow poplar, 1/2 or 7/8" thick, oak, 1/2" thick, and white pine, 3/8" thick. With boards delivered in proper thickness, the joiner could more easily lay out and cut his joints. Jigs such as a marking gauge to mark mortise-and-tenon joints and a bevel gauge to lay out consistent pins and tails for dovetails made preparations easy. Workmanship habits made the cutting of tenons or dovetails proceed quickly. We tend to romanticize about the construction process, but the joiners of this period could perform like human machines.[19]

The probate inventories also indicate widespread ownership of templates and patterns. Although many scholars have believed that template use was an urban phenomenon typical of large-scale production, patterns also proved worthwhile in a rural shop with infrequent or seasonal production. Using templates to lay out crooked legs, bracket feet, and skirt profiles saved considerable time within a small shop, and, combined with the mental templates of rote structural work, enabled the small-shop joiner to make a desk in about a week and a half and a case of drawers in about three weeks.[20]

The organizational structure of the joiner’s shop was also critical to its successful operation. The written records identify two basic coexisting approaches to furniture production in western Connecticut: the family-based shop and the individual shop. In the family shop, a master craftsman took on neighbors or kin and then sons, as they matured, to staff their shops. Such shops were part of a household economy that also included improved land for crops and pasturage for animals. Acreage varied but usually included one to five acres of improved land and five to thirty acres of unimproved land. The historical evidence of such family dynasties as the Durands of Milford, the Hubbells and Beardslees of Stratford, and the Prindles and Fabriques of Newtown attests to the success of such an approach.

For other joiners, continuing in the community was not desirable or possible. Drawn by the promise of a newly developing area or pushed out of a stagnant or overcrowded center, some joiners lacked the means or connections to purchase sufficient land to establish their own mixed agricultural/craft household. Many bought or even rented small lots of one acre or less. To compensate for their lack of productive land, such craftsmen were under more pressure to make a living from their services. They thus concentrated more on craftwork and irregular handyman work. The instability of their lifestyles meant that the family often lasted less than a generation in a town and continued to move along.

Social Aspects of Composition

With the exception of shops in the commercial centers such as Boston and Newport, the production of furniture in eighteenth-century New England was essentially a face-to-face negotiation between the joiner and his customers. The customer would purchase a piece already assembled or specify a certain combination of features. In the latter case, the patron would have a more active role in the craftsman-client relationship, but the joiner still determined the form, decoration, and trim from his repertoire or through his own understanding of the desired style. The artisan controlled the “nature of work”—the physical knowledge of materials and techniques and its application—whereas the community controlled the “context of work.” The joiner allocated his time and skills among the members of the community as he saw fit, while the community constantly judged his performance and bestowed him with a reputation. It was therefore important for the craftsman to understand and respond to his community. After all, the local clientele ultimately determined the need for and success of a single joiner or the viability of several joiners.[21]

Apprenticeship introduced boys to the role of the joiner within that particular community and exposed them directly to the opinions and expectations of the town. Schooled in socialization as well as technical skills and conventions, the young artisan developed a personal expression that blended empirical craft techniques and local aesthetics. It is essential to gain an understanding of the local context—the existing views of material life, local notions of appropriateness, and limits of variability. A joiner’s cultural acumen and judgment of the market allowed him to practice a dynamic craft, but this dynamism was dependent on his patrons. Just as a kit of tools and learned techniques shaped the craftsman’s range of possibilities, so did the needs, aspirations, and expectations of his clientele.[22]

Due to the social context of the craft, most joiners found it easiest to remain in the town in which they were trained. Knowledge of local preferences, established accounts with neighbors or relatives, and familiarity with local labor and materials certainly gave local joiners an edge. A less tangible advantage was his internalization of local aesthetics. Within a familiar environment, he continued to learn attitudes and techniques for design and fabrication. His training conditioned him to recognize that particular community’s needs and provided him with the skills currently in demand. If new techniques were observed or introduced by a newly arrived craftsman, the locally trained joiner perceived these changes from a viewpoint similar to the majority of his customers. Work performed in such a context tended to be traditionally based, but not unchanging.

On the other hand, a joiner trained in one community but active in another often had different experiences. His learned techniques and the customers’ demands may not have aligned so neatly. To continue his trade, such a joiner had to be more willing to alter his internalized approaches, especially those concerned with decoration and forms. To survive he incorporated different techniques seen in work by other craftsmen, paid more attention to new forms produced elsewhere, or gave greater weight to his customers’ requests. If he worked in a community with joiners trained in a number of different traditions, he had many techniques from which to draw.[23]

To understand the social context of furniture making, it is essential to reconstruct the social and economic structure of the community over time and to identify the backgrounds of the joiners. Particular attention should be paid to periods of dynamic growth or internal stasis and to turning points in these trends. For example, the prosperous coastal town of Stratford experienced considerable cultural flux during the 1710s and 1720s: the Anglican church established its first Connecticut parish there, several teachers at Yale College who converted to Anglicanism in 1722 had close ties with the community, there was trade with Boston merchants and with Anglo-Dutch traders on Long Island, and two immigrant English joiners, Thomas Salmon and Samuel French, settled in the town. French and Salmon introduced a British vernacular tradition that blended with Boston and New York work to become a distinctive Stratford Georgian style. This style became the standard for much of the century as an Anglican–Old Light coalition established a cultural hegemony in the 1740s.[24] Stratford’s selective conservatism affected clients and makers alike. Inventory references after 1750 were sprinkled with evidence of new fashionable and expensive furniture forms such as sideboards, breakfast tables, and easy chairs, signifying the availability of these products and an awareness of them. These forms appeared infrequently, however. People of all income levels owned substantial quantities of furniture, but they favored traditional forms. They purchased expensive case furniture, particularly cases of drawers, dressing tables, and desks, and large quantities of chairs, especially turned and crooked-back chairs. For much of the last half of the century, the conservatism even influenced younger households, who acquired traditional furniture. During the first decade of the nineteenth century, joiner Lewis Burritt made several inlaid mahogany tables, but he still satisfied the traditional demands. He made chests, cherry chests of drawers or desks, and even fiddleback and york chairs. The latter had been fashionable chair forms in the 1740s.[25]

Brewster Dayton, who trained with an English joiner and had access to many sophisticated forms and techniques, restricted his performance in Stratford. Much of his work was rooted in a vocabulary established before 1750. The proportions, tympanums, and crowns of his two signed cases of drawers from 1784 (figs. 13, 14) closely resemble those features on Long Island furniture of the 1740s. To this Anglo-Dutch work he blended the carved feet and scrolled knees introduced by his master. Dayton’s probate inventory and various account book references also indicate that he made slat-back, fiddleback, and crooked-back chairs, all of which are based on traditional turned chair forms. Even the primary woods of his furniture—particularly sycamore and subgrade cherry—reflect his reliance on local networks. The artifactual evidence points out the limitation of the local clientele.[26]

The Hubbell shop of Stratford evidently enjoyed slightly greater latitude. Whereas the surviving Dayton work features only pad or carved feet, the Hubbells offered a variety of feet for their case furniture: pad feet, bracket feet, carved feet, and ball-and-claw (figs. 3, 15–17). Furniture attributed to that shop is also distinguished by a greater variety of primary woods. Of all the identifiable Stratford shops, it is the only one to use walnut and mahogany during the last half of the century. Ebenezer’s brother-in-law, Captain John Brooks, a merchant who was the “principal inhabitant of Stratford,” provided the Hubbell shop with these imported woods. The handling of the ball-and-claw feet also suggests an external influence. The Hubbell feet closely resemble Philadelphia work, as does a set of joiners’ chairs that might have been made in the Hubbell shop (fig. 18). Chairs of this type are listed in John Brooks’s probate inventory of 1777, which included “New furniture at Hubbells”—“1 Case Black Walnut Draws £8:10:0, 6 Cringle Back do Chairs @ 20/ £6, 1 great Chair £1:5:0.” Although the Hubbell shop could make high-style case furniture and joiners’ chairs, the bulk of their work was executed in a simpler fashion. Most surviving chairs that relate to the single set of joiners’ chairs are fiddleback and crooked-back versions.[27]

In contrast to the stylistic cohesion of Stratford was the stylistic frenzy of the Woodbury area between 1750 and 1800. In the middle of the century, Woodbury experienced considerable growth because it served as a gateway and center for the newly settled and developing Litchfield County. Established proprietors controlled land distribution, but new inhabitants, including craftsmen, arrived from all parts of Connecticut. Much of the surviving furniture from the middle of the century reveals the varied origins of the population. A case of drawers made in March 1755 by Silas Butler (fig. 19) blends Connecticut Valley (the legs and skirt in particular) and coastal Connecticut (the architectonic crown molding and carved shells) traditions. The work of another shop (fig. 20) and chairs (fig. 21) belonging to some of the leading citizens manifest a similar synthesis of traditions. The coherent look of the case furniture and the traditional character of the chairs mirror the evidence in the probate inventories of the 1750s and 1760s. Furniture listed in these estates resemble those of the surrounding communities and include painted turned chairs, chests, chests with drawers, simple tables, and cases of drawers.[28]

In the 1760s an entrepreneurial class of proprietors in Woodbury began to organize the export of beef and pork for the New York market during the Seven Years War. After hostilities ceased, the merchants continued to ship meat to New York for local consumption and for export to the West Indies. During and after the Revolution, these Woodbury merchants expanded their business, providing food and blankets for the war effort and shipping dairy products such as cheese and butter, as well as meat, to New Haven and New York from the 1780s through the first quarter of the nineteenth century. Woodbury’s stratified social structure, a development of the mid-eighteenth century, was ideally suited for the export trade. Proprietary families such as the Hinmans, Stiles, Osborns, Tomlinsons, and Bacons controlled the disposition and rental of lands to the new immigrants and orchestrated the gathering of surplus agricultural products. These merchants did, however, suffer from local and extralocal pressures. Due to weather fluctuations and family allocations, the merchants could not count on consistent quantities of surpluses. Elaborate credit relationships with New York and New Haven merchants and the changing needs of a distant market also provided an element of vulnerability.[29]

The tenuous socioeconomic status of the proprietary merchants gave rise to a certain status anxiety that affected furniture taste in Woodbury. As the proprietary class became competitive, they exerted an influence upon the context of craftwork. They sought expensive furniture, distinguished by elaborate decoration, time-consuming workmanship, and an expansive variety of forms. Many of the local elite began to purchase crooked-back (fig. 22) and joiners’ chairs (fig. 23), tea tables (fig. 24), and a variety of large case furniture including desk-and-bookcases. Jabez Bacon, who reportedly controlled the New York pork market, may have even sought to control fashion in town by sponsoring Windsor chairmaker Nicholas Jebine, who emigrated from New Haven in 1794. Jebine rented a house and shop on land that had been leased to Bacon. Documentation that Jebine provided Bacon with Windsor chairs and the inclusion of sixty Windsors in Bacon’s store inventory of 1807 provides additional evidence that Bacon had close ties with Jebine. Several surviving Windsors owned in Woodbury resemble New Haven work (fig. 25).[30]

The stratified social structure not only stimulated the demand for a wide variety of work and styles but also helped to ensure the presence of joiners who were willing partners in the competitive furniture trade. The proprietary system did not allow many yeomen craftsmen to prosper in Woodbury. The biographies of joiners active in Woodbury reveal considerable turnover in the trade; few were trained locally or remained in town. Craftsmen immigrated from various parts of Connecticut, worked for several years, and then moved on. Joiners such as William H. Peabody of Norwich, John Whitehead Gould of Branford, or Billious Hill of Goshen purchased or rented only an acre of land or less and therefore could not establish themselves within the mixed agricultural economy. As a result, they depended almost entirely upon their craftwork and allocated their time and energies accordingly. It was a period of intensified industry and specialization in cabinetmaking. With varied backgrounds and constant mobility among joiners working in an increasingly competitive trade, Woodbury’s furniture trade was unusually complex and dynamic, a good match for its entrepreneurial, image-conscious, outward-oriented proprietors. One shop worked in a Philadelphia-inspired manner (fig. 26), while another shop distinguished itself by offering a wide variety of goods that reflected familiarity with many different regional traditions (figs. 27-32).[31]

Even though permanence and learned techniques often resulted in traditional but evolving styles, and mobility and chosen techniques often resulted in rapid stylistic change, we should avoid drawing simple polarities. All furniture blends the familiar and the new; what is different is the proportion of each and where change is permitted. Similarly, in studying Connecticut furniture, we should not automatically draw a distinction between the traditional, Old Light western part of the colony and the cosmopolitan, New Light eastern section. The analysis of specific craftsmen-community relationships is essential.

The Cultural Significance of Joiners

In eighteenth-century rural New England, a world characterized by increasing population density, flourishing coastal trade, and chronic agricultural underemployment, a craft skill such as furniture making served an increasingly important function. Craft skills had always been an integral part of families’ strategies for estate settlement, but certain trends in the eighteenth century endowed it with new importance. The expanding population, shrinking supply of unsettled land, and increased accumulation and consumption of household goods shifted the balance of craft and farm work. Whereas craft employment had been subordinate to agriculture, by the end of the eighteenth century craft activity advanced to the lead. As many household farms became smaller and the increased population demanded more goods, craft skills gained stature. Whether in a stagnant or a dynamic rural area, furniture makers personified the adaptive resiliency that became a celebrated trait of the New England character in the eighteenth century. Furniture making reflected and embodied the prevalent values of the period: the familial priority of permanence and stability and the pragmatic need to conduct some entrepreneurial activity with the external market.[32]

Many New Englanders placed particular emphasis on permanence and stability. By the mid-eighteenth century, the subdivision of family lands throughout several generations had taxed the limited land resources and was creating impractically sized farms. To preserve stability, agrarian families adopted various strategies to keep their children on the family land or within a community of kin. Fathers provided sons with craft training and thereby enabled them to earn a living with a smaller plot of arable land. Part-time artisan work thus provided the means to subdivide family lands further while maintaining economic viability and preserving the family identity in town. Combining craftwork and farming allowed a particular family to balance numbers and resources and to strengthen ties within the community. Craft shops produced needed goods for the expanding population and drew on the services of other community members.[33]

In families with several generations of woodworkers, joiner’s skills provided both a livelihood and a legacy. Craft skills and tools—like land for sons of farmers and furnishings for daughters—became another form of “property” that could be transmitted through the family network. Like real and personal estate, skills and tools allowed the succeeding generation to establish its own productive household unit while maintaining cross-generational rights and responsibilities. The success of this artisan strategy can be seen in the several families who produced several generations of joiners within each town: the Durands in Milford, Hubbells in Stratford, and Prindles in Newtown.[34]

Other New Englanders placed slightly less emphasis on geographic permanence. If pressure for land continued unabated, the father could acquire land in a nearby town or on the frontier. Then the father assisted his son’s migration by deeding him the land. Sons with joiner’s skills probably found such relocation easier. Demand for joiner’s work permitted some sons to establish themselves in a nearby community, close to kin support. For instance, John Fabrique, a Newtown cordwainer, provided two sons with woodworking skills. David and Bartimeus Fabrique were then able to practice the house joiner’s trade in Newtown and the adjacent communities of Derby, Southbury, Woodbury, Roxbury, and New Milford. Other families developed multi-generational dynasties of house and shop joiners who formed regional networks. Among the many examples of such families in western Connecticut were the Beardslees, Prindles, and Booths.[35]

Those who moved further away often moved with other kin or people from the same town. Joiners in such a group preserved the group’s cultural identity by providing familiar products. Like the English joiner who emigrated to New England in the 1630s, the rural Connecticut joiner who moved north or west in the early-nineteenth century created physical and psychological comfort for others in a new environment. Lemuel Porter, a Waterbury joiner, moved west to Tallmedge in the Western Reserve in 1818 and built a church and several houses that recreated the feel of Litchfield, Connecticut.[36]

Craft skills could also be used in more innovative ways. Instead of being pushed into the joiner’s trade by familial pressures, some sons were pulled into it. The growing population fostered a growing need for furniture, and such structural shifts gradually and unevenly affected cultural values. Some sons of farmers took advantage of the available opportunities. Lacking the strength of family tradition, farmers’ sons like Arcillus Hamlin may have been less tied to tradition and therefore more innovative in their work. Hamlin, the son of a Sharon farmer, worked as a joiner in Newtown. His 1827 inventory listed many items that were unique or rare for Newtown joiners such as trunks, sheets of veneer, and bureaus. Such free agent joiners were also more willing to migrate as individuals. William H. Peabody, born in Norwich, worked for a few years in Stratford, sold his shop in Stratford and moved to Woodbury, worked in Woodbury for twelve years, and then returned to Stratford. Joiners like Hamlin and Peabody may have perceived their skills as a marketable commodity for an individual rather than as an adaptive strategy for family continuity and identity.[37]

Woodworkers’ sons who inherited skills and tools sometimes made different uses of these inherited traditions as economic patterns changed and altered their attitudes. Justin Hobart Jr., the son of a Fairfield shop joiner, received his father’s home and shop in 1797 but preferred to seek his fortune as a journeyman cabinetmaker in New York City. His entrepreneurial attitude was expressed in several letters to his sister Mary. In some of the early letters from 1797, Hobart reported of constant work and good earnings, however, within three years he lamented:

I dont think that I shall work Journey work any longer their is no profit in it I dont Earn but Just Enough to pay my Expenses and I believe I can doe that in the Country . . . I have work on hand that will take me about 6 weeks to finish and then I intend to quit working Journey work for a Spell . . . if their is going to Bee so many traders in Fairfield it will Doe for me to Carry on the Cabinet Business their they Cant get that away from me.

Nevertheless, Hobart remained in New York a while longer, for in 1804 he took on John Jackson as an apprentice.[38]

Silas Cheney, a member of another woodworking family from Manchester, Connecticut, moved to Litchfield in 1799, probably with the intent to exploit the growing economy in northwestern Connecticut. Such awareness was fully revealed by his establishment of a rural manufactory for the production of furniture. He employed several journeymen and apprentices at one time and for outwork drew on woodworkers in nearby Connecticut and Massachusetts towns. A Lenox, Massachusetts, woodworking shop, West & Hatch, provided Cheney with parts for kitchen and Windsor chairs. One of Cheney’s journeymen, Lambert Hitchcock, went on to refine some of these practices in the large-scale production of turned, flag-seated fancy chairs.[39]

In the eighteenth century, similarities in technical repertoires, tool ownership, and shop layout linked the joiners of western Connecticut. However, these artisans made different uses of the same processes and equipment according to traditions in which they were trained and the context of their mature work. By identifying the diagnostic details of craft traditions, it is possible to follow the flow and confluence of ideas and people over the New England landscape. Changes in consumption patterns or production rhythms often coincided with shifting commercial relations and increased involvement with external markets. Documentary evidence of craftsmen and communities, used in conjunction with artifactual evidence, offers explanations about why different towns supported different types of joiners and contrasting tastes in furniture during the eighteenth century.

Ibid., pp. 18, 320–45. Goodrich’s phrase “articles of use” is noteworthy, for it resembles the Marxist concept of use value. For a historiographical review that characterizes the intense non-market exchanges of rural New England households, see Alan Kulikoff, “The Transition to Capitalism in Rural America,” William and Mary Quarterly 46, no. 1 (January 1989): 122–26.

Robert Seybolt, Apprenticeship & Apprenticeship Education in Colonial New England & New York (New York: Columbia University Teachers College, 1917); Paul Douglas, American Apprenticeship and Industrial Education (New York: Columbia University Press, 1921); and Ian Quimby, Apprenticeship in Colonial Philadelphia (New York: Garland Publishing, 1985).

Account Book of Joseph Shelton of Stratford, 1728–1789, pp. 22, 30 (Yale University Library, New Haven, Conn.); Account Book of Ephraim Curtis of Stratford, 1743–1775, p. 264 (Connecticut Historical Society, Hartford, Conn.); and Fairfield District Probate Records, vol. 14, p. 520 (Fairfield Town Hall, Fairfield, Conn.). Information on woods drawn from a survey of Fairfield District Probate Records, vols. 4–20. On local economic activities, see Connecticut Archives: Industry and Connecticut Archives: Trade Maritime Affairs (Connecticut State Library, Hartford, Conn.). On the Stratford examples, see Account Book of John Brooks Jr. of Stratford, 1784–1824 (Discovery Museum, Bridgeport, Conn.) and Account Book of Lewis Burritt of Stratford, 1794–1838 (Stratford Historical Society, Stratford, Conn.). For comparative insights on Marblehead joiners who worked according to maritime rhythms, see Account Book of Joseph Lindsey of Marblehead, 1739–1764 (Winterthur Museum Library, Winterthur, Del.); Jobe, “Urban Craftsmen and Design,” pp. 12–13; Account Book of Nathan Bowen of Marblehead, 1775–1779 (Winterthur Museum Library, Winterthur, Del.); Philip Chadwick Smith, ed., The Journals of Ashley Brown (1728–1813) of Marblehead (Boston: Colonial Society of Massachusetts, 1973), 2: 646; and Richard Randall Jr., “An Eighteenth Century Partnership,” Art Quarterly 23, no. 2 (Summer 1960): 152–161.

Cooke, Making Furniture in Preindustrial America.

Ibid. For a similar response in eastern Connecticut, see Robert F. Trent, “The Colchester School of Cabinetmaking, 1750–1800,” in The American Craftsman and the European Tradition 1620–1820, edited by Francis Puig and Michael Conforti (Minneapolis; Minneapolis Institute of Arts, 1989), pp. 112–35; and Robert F. Trent, “New London County Joined Chairs: Legacy of a Provincial Elite,” The Connecticut Historical Society Bulletin 50, no. 4 (Fall 1985): 15–186.

Cooke, Making Furniture in Preindustrial America.

Ibid.

The traditional emphasis on the lineal family and its influence upon adaptive strategies is discussed in Jedrey, The World of John Cleveland; Jones, Village and Seaport; Robert Gross, The Minutemen and Their World (New York: Hill and Wang, 1976); and Henretta, “Families and Farms,” pp. 3–32.

Benno Forman, “The Crown and York Chairs of Coastal Connecticut and the Work of the Durands of Milford,” Antiques 105, no. 5 (May 1974): 1147–54; Edward Cooke Jr., “Selective Conservative Taste,” p. 44; Account Book of John Brooks, Jr. of Stratford, 1784–1824, pp. 20, 81; and Bridgeport Probate District, Docket 2232 (Connecticut State Library). For information on the Prindle family, see Edward S. Cooke Jr., Fiddlebacks & Crooked-backs: Elijah Booth and Other Joiners in Newtown and Woodbury, 1750–1820 (Waterbury, Conn.: Mattatuck Museum, 1982), p. 90. A similar pattern of craft families and traditionalism existed on eighteenth-century Long Island (Failey, Long Island is My Nation, pp. 191–200).