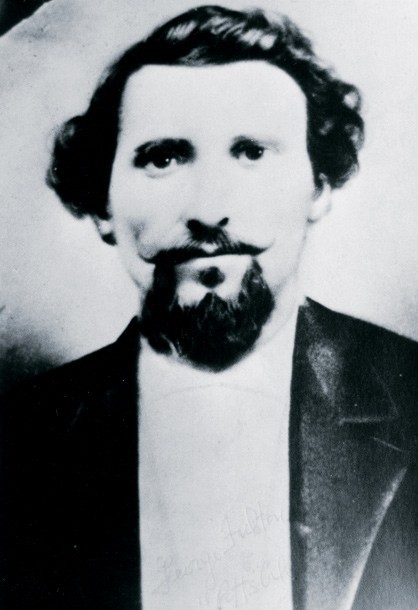

hotograph of George N. Fulton, ca. 1867–1875. (Courtesy, Alleghany County Historical Society, Virginia.)

Storage jar, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 10". (Unless otherwise noted, all objects are from the author’s collection and photos are by Gavin Ashworth.) A one-gallon straight-sided storage jar with elaborate brushed manganese floral or tree decorative motif and signature

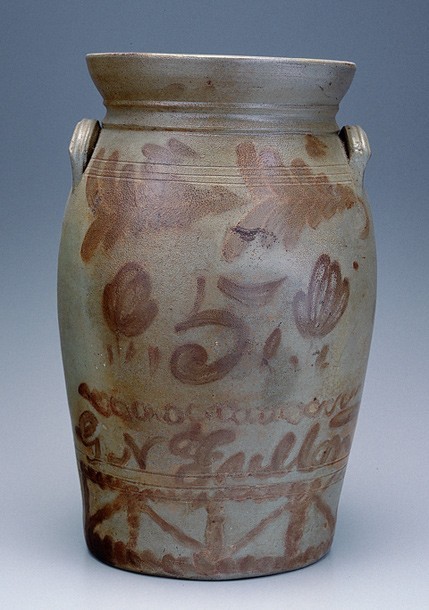

Churn, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 14 3/4". This cobalt decorated churn is embellished with a large floral element with two upright leaves highlighted with dots, two “3” indications of vessel capacity, and a “G. N. Fulton” signature highlighted by two wavy bands. Note the similarity of this decoration and that on the jar depicted on the left in fig. 16.

Churn, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 17 1/2". (Private collection; photo, Kurt Russ.) A five-gallon churn with elaborate brushed manganese dioxide floral decoration highlighted (or overpainted) with cobalt oxide, including a centrally placed floral spray surrounded by leaves, a “5” indicating vessel capacity, and a large signature.

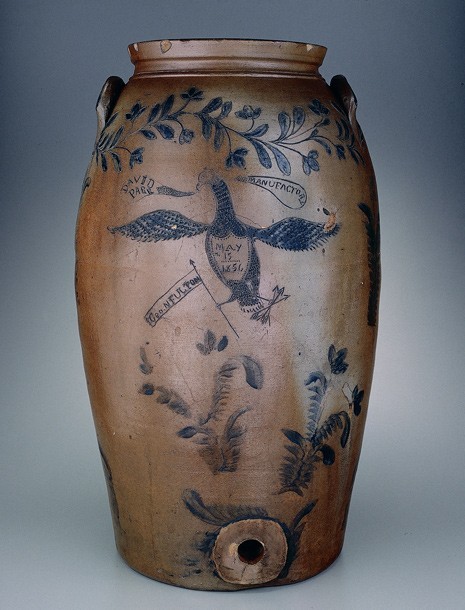

Beer or water cooler, George N. Fulton, David Parr’s Pottery, Richmond, Virginia, 1856. Salt-glazed stoneware. H. 29 1/4". (Courtesy, The Greenbrier; photo, Gavin Ashworth.) A monumental twenty-gallon beer or water cooler. The incised word “Painted” appears on the vessel to the right of the arrows in the eagle’s talons and strongly suggests that Fulton was involved with the vessel’s decoration, if not manufacture.

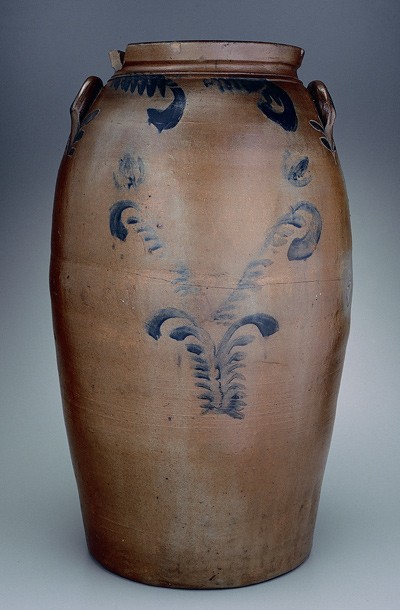

Reverse of the stoneware cooler illustrated in fig. 5, showing brushed blue cobalt floral decoration at the shoulder and horizontal flowers on either side. These long multipetaled, single-bloom horizontal flowers seem to characterize vessels from Parr’s pottery, often appearing below the maker’s stamp on the reverse of the vessel and/or beneath its handles.

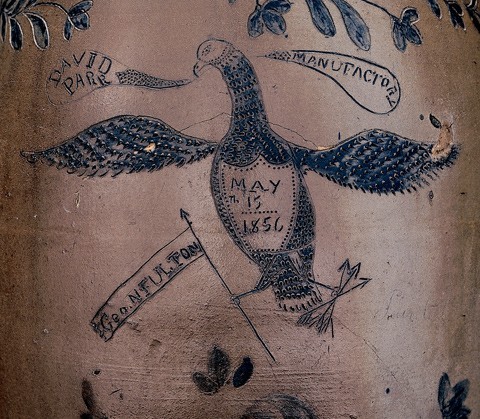

Detail of the cooler illustrated in fig. 5, showing an incised and cobalt-decorated eagle with spread wings and opposing banners extending from the beak reading, “DAVID PARR” and “MANUFACTORY.” The shielded chest contains the date “may 15 1856,” and the banner in its left talon reads “GEO. N FULTON.”

Detail of the stoneware cooler illustrated in fig. 5, showing the extruded crescent-shaped applied handle brushed with blue cobalt, well-formed rim, and treatment at the shoulder, as well as incised and cobalt-filled floral vines at handle terminations and an incised “20” (indicating vessel capacity) above two opposing incised leaves.

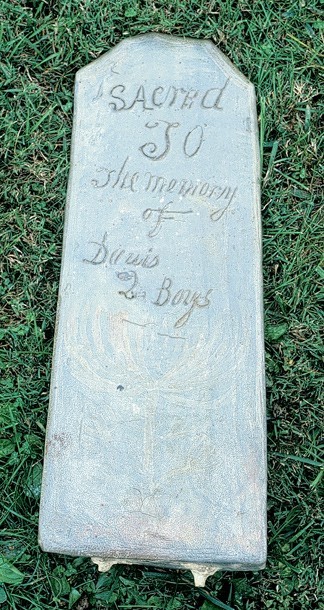

Grave marker or tombstone, Fulton Pottery, Alleghany County, Virginia, ca. 1874. Salt-glazed stoneware H. 42 1/2". (Photo, Kurt Russ.) The hand-modeled stoneware tombstone contains a tree-of-life motif in relief.

Reverse of the grave marker illustrated in fig. 9, showing incised inscription, “Sacred to the Memory of Davis 2 Boys” and brushed manganese decoration, which is barely visible because of poor contrast with the tombstone color.

Miniature jar, Fulton Pottery, Alleghany County, Virginia, 1881. Salt-glazed stoneware. H. 3 1/4". Incised “G. N. Fulton 1881.”

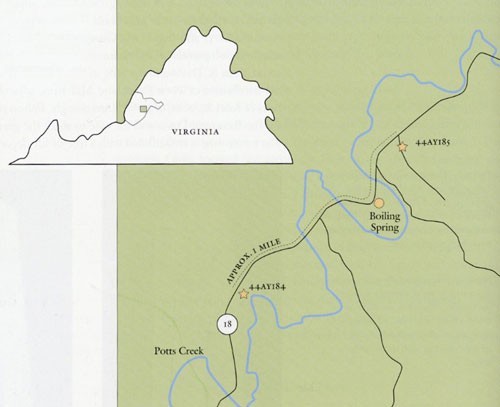

Map showing the location of Fulton’s Pottery (44ay184) and Waddell’s Pottery (44ay185) near Boiling Spring in Alleghany County, Virginia (from 7.5 minute U.S.G.S. Jordan Mines Quadrangle Map).

Examples of Alleghany County pottery. Left: Jar, T. R. Waddell, 1850– 1870. Salt-glazed stoneware. H. 13 1/4". Right: Jar, G. A. Brown, 1850–1860. Earthenware. H. 8 1/2". Both of these examples bear the impressed marks of their makers.

Fragment of a cake crock, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. (Courtesy, Laboratory of Archaeology, Washington and Lee University, Lexington, Virginia.) Partially reconstructed from sherds excavated at Fulton’s Pottery Site (44ay184), Alleghany County, this vessel exhibits brushed manganese floral decoration and the capacity designation “2.”

Canning crocks or jars (also known as wax sealers), Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 9" and 10". The quart-size jar at left is brushed with manganese floral or tree decoration and the signature “G. N. Fulton” near the base. The slightly larger jar at right is brushed with blue cobalt floral decorative motifs, including flowers, leaves, and horizontal bands enclosing the centrally placed signature.

Storage jars, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware with cobalt decoration. H. 9 1/4" and 9 1/2".

Storage jars, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware with manganese brushed decoration. H. 10" and 7 1/4".

Jug, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 12 1/2". A semi-ovoid jug with brushed blue cobalt decoration, including a drooping flower, the initials “G.N.F.,” and a “1 1/2”-gallon capacity designation.

Bowl, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 5 7/8". A bowl with approximately one-half-gallon capacity embellished with brushed blue cobalt floral decoration, horizontal squiggly bands, and a full signature.

Milk pan or shallow bowl, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 6 1/8". This robust, wide-mouthed vessel has brushed manganese floral decoration and the signature “G. N. Fulton” above its base.

Cake crock, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 9 3/4". This straight-sided vessel is decorated in cobalt blue with a horizontally oriented floral spray, a centrally placed signature, and, near the base, double crosshatched marks enclosed by two horizontal wavy lines with a “3”-gallon capacity designation in the center. Compare the decorative embellishment at the base with that executed in manganese on the churn illustrated in fig. 26.

Pitchers, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. (a) H. 10 1/2". A one-gallon pitcher with a well-defined beaded rim, horizontal blue lines at the spout flanked on either side by blue flowers, and the signature “G. N. Fulton” above brushed cobalt floral motifs. (b) H. 10". A one-gallon pitcher with a well-defined shoulder above three concentric incised bands, blue vertical lines on either side of the spout flanked by additional floral motifs, and wavy lines and floral motifs across the front of the vessel, the initials “g.n.f.,” and horizontal lines on the handle. (c) H. 8 1/2". A pitcher with a prominent banded or incised rim, pronounced shoulder above two incised rings with two similar incised lines near base, and a well-defined base; cobalt decoration includes vertical stripes at spout, floral leaves, dots, and the initials “g.n.f.” (d) H. 8 1/4". A half-gallon pitcher with a prominent rim, well-defined shoulder, two incised concentric rings around the upper mid-section and at 1/2" above the base, elaborate brushed cobalt floral decoration including dots, squiggly lines, and floral motifs around the rim, with lines and the initials “g.n.f.” above the floral motif.

Pitchers, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. Left: H. 9". The thinly glazed well-potted dark gray pitcher exhibits simple curvilinear floral motifs. Right: H. 7 7/8".The smaller, light-gray pitcher has textured salt-glaze and stylized floral motifs.

Churn, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 16". This four-gallon churn is decorated with a brushed blue cobalt floral design and includes a centrally placed “palm” tree and signature.

Churn, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 15 1/4". This three-gallon churn has a flaring rim and applied extruded crescent handles and exhibits a prominent brushed blue cobalt floral motif with blossom, “3,” and signature.

Churn, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 17 1/8". A five-gallon churn with a flaring rim, well-defined collar, and applied crescent-shaped extruded handles exhibiting elaborate brushed manganese dioxide decoration, including both horizontally and vertically oriented floral motifs, a centrally placed “5” indicating vessel capacity, and the signature “G. N. Fulton” enclosed by horizontal wavy lines. At the base a series of squares with intersecting diagonal (or 45°) lines appear to form an artificial base, or platform, for the decorative embellishment above.

Jar, bowl, and pitcher, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. Jar: H. 8". A quart-size, straight-sided jar with folky manganese floral decoration, including a prominent blooming tulip resembling a musical lyre flanked by vertical floral vines on both sides. Bowl: H. 7 1/8". An approximately one- half-gallon bowl with a flat, flaring rim, three incised concentric rings, and rather detailed floral motifs, including flowers with dotted leaves and the signature “G. N. Fulton” at the base. Pitcher: H. 8". A quart-size pitcher with profuse manganese floral decoration and the signature “G. N. Fulton” at the base. The color of the manganese decoration, manner of execution of the decorative motifs with small fine-line, detailed brushstrokes, and the color of the vessels with a fine, well-processed clay paste suggest that these vessels may have been made and decorated by the same hand.

Jug, storage jar, and bowl, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 14 3/4", 9 3/4", and 10". These Fulton stoneware vessels are embellished with brushed blue cobalt oxide and manganese dioxide floral decoration, and include the signature “G. N. Fulton.”

Sugar bowl, Fulton Pottery, Alleghany County, Virginia, ca. 1880–1885. Salt-glazed stoneware. H. 3 3/4". This diminutive, well-potted, thin-walled sugar bowl with brushed manganese floral decoration below the rim was found in Alleghany County. It was probably produced during Fulton’s last few years of production in Alleghany, when he was experimenting with some nonstandard forms, this piece being similar to art pottery pieces produced by his family in Ohio.

Jar, Fulton Pottery, Alleghany County, Virginia, 1867–1885. Salt-glazed stoneware. H. 8". Manganese floral decoration of Germanic tulip and associated leaves and vines.

Having acquired traditional pottery-making skills at his family's pottery business in Ohio, George N. Fulton brought meaningful training, enthusiasm, and youth to his chosen profession, qualities that were to serve him well as he made his way to Virginia for employment (fig. 1). First working in the Richmond Pottery of David Parr, then establishing a significant and long-lived operation in Alleghany County, and finally ending his career in nearby Botetourt County, Fulton's mark on the Virginia craft industry is well established.[1] As a result of his extensive output, variety of forms produced, and frequency of elaborate and unique decoration—involving brushed and slipped blue cobalt and manganese floral motifs often accompanied by either initials or a full signature—his significant and enduring contribution to Virginia's pottery tradition can now be more fully documented and explored (figs. 2-4).

The success of Fulton's quarter-of-a-century endeavor in rural Virginia must be viewed in the context of industry trends elsewhere in the state, where potters were faced with the difficult choice of either closing their operations entirely or significantly altering their character in the face of advancing industrialization.[2] It appears that Fulton embraced few, if any, of the new technologies or changing trends and yet did not have to close his business. Was it the rural nature of his operation that allowed him to avoid these dilemmas? While the location of his shop undoubtedly was relevant, his keen sense of craft, understanding of local need and demand, utilization of decoration reflecting cultural symbols shared with his customers, effective basic marketing strategies, and hands-on participation in and ultimate control over all aspects of his business were factors that combined to allow him to escape the crushing fate industrialization brought to others.

Historical Overview

James Fulton, born in 1794 in Loundon County, Virginia, married his second wife, Mary Ellen Newman (from Prince Edward County, Virginia), in 1833. George W[illiam] N[ewman], their first child, was born in 1834, and by 1835 his family had moved to Fultonham in Muskingham County, Ohio. At this time the family included a stepbrother, William Henry (b. 1823), and a stepsister, Mary (b. 1823), both the product of James's first marriage (ca. 1823) to Elizabeth McGeorge, who died in 1829 in Farquier County, Virginia. By 1836 Mary gave birth to another son, Robert James Fulton, in Fultonham.[3]

Although unconfirmed, it is likely that James was a potter while in Virginia and moved to Ohio to capitalize on the industry's growth there. Not surprisingly, James's venture was successful, and he and his sons became deeply immersed in the area's thriving pottery industry. Identified historically as potters operating kilns in Marietta and Zanesville, James and his sons had a continuing impact on the industry in Ohio during its transition from a traditional craft technology to an evolving industrialized art pottery concern. Apparently Robert James operated a kiln in Marietta and later worked at the Weller pottery, while William Henry worked in Zanesville with his father.

Late in 1855 George's mastery of traditional potting skills and his intimate involvement in the Ohio pottery industry enabled him, at the age of twenty-one, to travel east to Virginia and gain employment with David Parr's thriving Richmond stoneware factory. After some six years of employment, Fulton enlisted with the Union army on July 23, 1862, at Meadowbluff, Virginia, as a private in Company E, 9th Regiment, Virginia - West Virginia Infantry. In November 1864 he was transferred to Company B, 1st Regiment, Virginia - West Virginia Infantry, with his final discharge as a private on June 14, 1865, at Parkersburg, West Virginia.[4] Although not well documented, his participation at the Parkersburg Stoneware Factory is evidenced by extant wares showing his decorative influence and, in a few cases, his signature on the otherwise standard West Virginia, and later Donaghho, forms.

After his service in the Civil War, brief employment in Parkersburg, and marriage, Fulton moved to the Potts Creek area of Alleghany County, Virginia, and established a thriving pottery business, marketing his wares locally as well as in Fincastle, Blacksburg, and as far away as Richmond. Family tradition holds that Fulton escaped to Alleghany County after being captured and taken prisoner by the Confederate army near White Sulfur Springs, West Virginia, and, while making his way back to his regiment, discovered large deposits of valuable clay in a cave in the Potts Creek area.[5] Recognizing its quality, he laid out plans to return to the area, apply his pottery-making skills, and establish his own business to support his family and furnish the community with needed utilitarian vessels of "good stone body."

Fulton's Tenure at Parr's Richmond Pottery

Little is known of Fulton's role in the industry in Richmond save for family tradition—which holds that he traveled to Richmond for employment with David Parr in late 1855 and that he later established a pottery in Westmoreland County—and the survival of a spectacular piece of Virginia stoneware bearing his name.

The earliest extant piece of stoneware associated with Fulton's potting activity in Virginia is a massive twenty-gallon, salt-glazed beer or water cooler (fig. 5). It is tall, well potted, semi-ovoid, somewhat overfired, and profusely decorated, with a prominent rim, applied extruded crescent-shaped handles, and characteristic spigot receptacle. Decorative treatments (fig. 6) include an incised meandering flowering vine filled with cobalt blue draping the vessel's shoulders and an oddly shaped, incised, and blue-decorated eagle with open wings (fig. 7). Extending from the left and right of the eagle's head are banners that read, respectively, "DAVID PARR" and "MANUFACTORY." The eagle's shielded chest bears the incised date "MAY 15 1856," and in its talons are a flaglike banner displaying the name "GEO. N FULTON" and a cluster of arrows. Brushed blue cobalt tuliplike floral sprays adorn the areas below the eagle and above the spout opening, as well as the areas below both handles (fig. 8).

Although the form and decoration of this cooler bear little resemblance to Fulton's wares produced in Alleghany County, this does not necessarily mean he was not responsible for its production. A large, ten-gallon, straight-sided vessel produced by Fulton at the Parkersburg Stoneware Factory bears little resemblance to his later Alleghany wares, despite bearing his signature. It is clear that potters employed by a pottery, especially journeyman potters, conformed their production to the factory's established forms and ware types. The incised decoration seen here is rare on Virginia pottery and even more unusual for this mid-nineteenth-century period. It is likely this special piece was commissioned by Old Crow's Tavern, Crows, Virginia, and that Fulton, eager to exhibit his mastery of the trade, responded by creating a breathtaking cooler exhibiting a full range of decorative embellishments. It is said that after the tavern closed, the piece was sold at auction for $100. It was later offered by the purchaser for the same amount to the Greenbrier, where it has remained since 1963. Now displayed in the President's Cottage at the Greenbrier Hotel in White Sulphur Springs, West Virginia, this piece can be appreciated not only by Fulton's many descendants, interested Virginia ceramic researchers and historians, but by the public as well.

Both Fulton's 1855 departure from Ohio and the 1856 date incised on this vessel establish a terminus post quem (earliest possible date) for Fulton's association with Parr's Richmond manufactory, while Fulton's enlistment with the Union forces in 1862 pinpoints a terminus ante quem (latest possible date) for his involvement with Parr. A Richmond Whig publication dated April 15, 1865, lists the "D. Parr earthenware manufacturer" on Carey Street as suffering from "the recent great fire," although Ketchum's indication that Parr's operation continued until 1870 suggests post - fire revitalization and successful continuation for some five years.[6]

Fulton's Return to the Parkersburg, West Virginia, Area

Fulton's discharge from the Union army places him at Parkersburg, West Virginia, on June 14, 1865. This adds credence to the family history, which indicates that about 1866 Fulton returned to his father's hometown, Fultonham, Ohio, located just across the Ohio River from Parkersburg, and worked as the captain of the Ohio riverboat Ida, a cargo vessel.[7] His involvement with the Parkersburg Stoneware Factory is corroborated by the identification of a few extant wares manufactured at the Donaghho Factory that were embellished with Fulton's characteristic decorations and, on one ten-gallon example, his signature in brushed blue cobalt oxide.

In addition to providing reconnection with his family and interesting employment opportunities, Parkersburg also proved to be the home of his fiancée and, hence, the perfect site for their forthcoming marriage. Family history indicates that after their union both Fulton and his wife worked aboard the Ida, perhaps intermittently, during 1867 - 1869, while preparing their move to Alleghany County.

Fulton and Waddell in Westmoreland County

Family history is unequivocal with regard to Fulton's association with a potter named Waddell (or Wadill). It is suggested that they worked together both in Westmoreland County and in Richmond, Virginia, and that they both moved to Alleghany County to work as potters after the Civil War. While it has been impossible to find historical documentation placing Fulton or Waddell in Westmoreland County as potters or establishing Waddell's association with Fulton in Richmond, it is clear that they were closely associated as potters in Alleghany County.

Fulton Pottery at Potts Creek in Alleghany County

Fulton's serendipitous discovery of that valuable clay deposit during his service with the Union army paved the way for his return to Alleghany County and the establishment of his pottery in 1867 at Arritt's near Potts Creek. Shortly before his move, Fulton married Sarah Ellen Schaffer (Shaver) in Parkersburg, West Virginia, on September 30, 1867.[8] Apparently he leased the land on which the remains of his kiln still stand from D. M. Davis, the grandfather of the land's current owner. Documentary research confirms Fulton's continuing potting activities in 1870, when Fulton recorded a homestead exemption as follows:

I . . . hereby declare exempt . . . the following named property to wit: All of my household and kitchen furniture worth $175. All of the provisions laid in for the use of my family worth $25. All of the crockery or stoneware that I now have or may hereafter have on hand, that I have on hand being worth $175 {and $90 debts}. Signed, Dec. 7, 1870.[9]

Both his business and family grew over the next decade, so that by 1880 he had six children—four girls (Lola May, 11; Mary A., 6; Elizabeth, 2; and Amanda E., 1) and two boys (George R., 9; and John W., 4)—and had acquired two parcels of real estate: one acre on Potts Creek from the Reverend John B. Davis and his wife in 1876; and a six-acre parcel located at the confluence of Potts Creek and Mill Run, adjacent to the land of the heirs of John S. Arritt, in 1877.[10] Interestingly, Fulton produced a tombstone for the Reverend Davis and his wife to mark the grave of their two boys. The tombstone is embellished with a tree-of-life decoration in relief (fig. 9) as well as brushed manganese floral decoration and, on the reverse, is inscribed "sacred to the Memory of Davis 2 boys" (fig. 10). It was on the Davis tract of land that Fulton built a log home for his family residence. At the same time he constructed a log building for making and storing his wares. As early as 1875 Fulton began utilizing another nearby clay source on land owned by Moses G. Wright located some one-and-one-half miles distant from his pottery.[11]

His post-1880 activity is evidenced by a miniature stoneware jar incised "G. N. Fulton 1881" (fig. 11) and his listing as "Geo. N. Fulton, potter located at Arritts, Alleghany County," in the 1884 - 1885 Virginia Gazetteer (Richmond).[12]

The Fulton pottery kiln is located approximately one mile south of Boiling Spring, Virginia, being situated about thirty-five yards southeast of Route 18 in a relatively flat agricultural field (fig. 12). Recorded in 1936 in conjunction with a WPA project, the pottery site was tested archaeologically in 1987 by Washington and Lee University. The site consists of the remains of a circular stoneware pottery kiln forming a mound approximately twenty feet in diameter and rising some six feet above the ground surface, as well as an associated waster pile exhibiting heavy surface concentrations of salt-glazed stoneware waster sherds and various kiln furniture fragments located roughly six yards northwest of the mounded kiln remains. This site is identified by the Virginia Department of Historic Resources as 44AY184, Fulton Kiln A.

In close proximity and also situated along Pott's Creek is another pottery kiln site, 44AY185, originally identified as belonging to Fulton. Documentary and archaeological research determined this was the Waddell pottery, the second of three potteries involving some five potters identified in Alleghany County during the nineteenth century. Thomas Waddell appears on the 1850, 1860, and 1870 Alleghany County census records as a potter with birthplaces listed as New York, Pennsylvania, and Virginia, respectively.[13] A land deed dated August 15, 1857, shows Waddell being granted an interest in ninety-eight acres on Christley's Run.[14] Recovered stoneware sherds from the Christley's Run site bear the stamp "T. R. Waddell, Va" and extant vessels with the same stamp are quite distinct from those produced by Fulton. The proximity of the two sites provides further evidence of the Fulton-Waddell association recorded in family history as beginning in Westmoreland County, continuing in Richmond, and ending in Alleghany County. Although dissimilar from Fulton's ware, the Waddell wares are remarkably similar to extant vessels stamped "G. A. Brown, Va" (fig. 13), attributed to a contemporaneous kiln located on the top of Potts Mountain.[15] Although no documentary evidence of the Brown pottery has been identified, the similarities of the Brown and Waddell wares suggest the likelihood that John Brown and two of his sons, Gustavus and John W., were associated with Waddell circa 1850[16]

Limited archaeological excavations of Fulton's kiln suggest the presence of the remains of a relatively well-preserved, nineteenth-century circular updraft kiln and recovered salt-glazed stoneware pottery sherds from a variety of vessel forms (fig. 14), some decorated with either cobalt blue or manganese dioxide floral embellishments, capacity numerals, and the signature "G. N. Fulton" or initials "G. N. F.," and numerous kiln furniture fragments, including several draw trials.

In 1938 Marion Rawson conducted oral history research, which recorded traditional Appalachian lifeways. Among her documentation is a remarkable interview with Daniel Arritt, who as a young man lived next door to and worked in Fulton's pottery shop. The fascinating details provide insight into not only Fulton's operation but the very nature of this traditional craft industry in Virginia during the third quarter of the nineteenth century:

You see yonder out that door where the grass looks brown just over the knoll? That's where I dug the mud and carted it a mile and a half down to Fulton's shop. He had what you call a mill standing up two feet or so from the ground and about as big as a hogshead, that was worked by an old horse at the end of a sweep; I'd throw the mud or clay in there and the knives revolving would cut it up. When it was cut up enough we took it out in blocks about a foot square—it would be about as stiff as wheat dough—and carried it to the lathe, and old man Fulton would work it round and round so, running the treadle with his foot to make the platform revolve. He'd draw it up so and so and make it like the shape he wanted it to be, sometimes using a little piece of wood to fix it right, and when it suited him he'd take a piece of wire and cut under it to loosen it so he could pick it up and carry it into the dry room. It took five days to dry and when it was dry enough he'd take his bresh and paint his name in blue across it, the full name on the big crocks, and then put some of them fancy patterns out of his head on it. He got the blue indigo at the store in a chunk and softened it with a little turpentine—yes marm. When he had enough ware—a thousand gallons—we'd set it up in the kiln.[17]

At this point Arritt stopped his narrative and explained that the kiln was about eighteen feet in diameter and approximately the same height. It was shaped like an egg, with the fire door close to the ground on one side and the only other opening being the central chimney where the smoke and flames escaped. It is inferred from his description that the kiln was of the circular updraft variety, a common nineteenth-century kiln type. He also indicated that there were four iron bars stretching across the kiln above the flues, upon which rested stones placed about eight inches apart and arranged so that the crocks and pots could be set up on them and stacked on one another, separated by little crockery plates or kiln furniture. This arrangement allowed the vessels to be exposed to equal heat on all sides. The kiln held one thousand gallons of ware, with pot quantities being computed by adding together half-pints, quarts, and gallons, represented by the various vessels to be fired.[18] Arritt continued:

We burnt the ware for three days and three nights and I've set up and watched many a batch and tended fire. When the ware was burnt just enough I'd go up on top of the kiln, and looking in it would seem just like a raging iron furnace, and I'd take a right smart of salt and throw it down over the ware, inside and out. You had to leave the ware where it stood for two days to cool off before you could draw it. Then it was my job to load it onto a wagon—350 gallons would make a good two-horse load—all sizes, and it brought fifty cents for a gallon and seventy-five for the bigger ones, wine crocks and water coolers.

You know, marm, this was good stoneware, not that no 'count red earthen ware. You could bile in our stoneware. I've driv the wagon many a time to Blacksburg, and there that old Waddel that sold the redware would see me coming and shout, "What you bringing that no 'count stuff to this town for?" And I'd shout back, "Yours is the no 'count stuff, aint burnt to a body. Mine's burnt to a stone body. Give me a piece of your old no 'count ware, I want to pitch it and one of mine down the road a little piece." So I pitched one of my crocks down the road twenty feet and it never broke none. His'n? He daren't give me any. He went out of business afore long. Fulton's ware was good stone body.[19]

Wares of "Good Stone Body"

A fascinating variety of wares, some unique to Virginia stoneware, characterize Fulton's production. Fulton's application of "those fancy patterns out of his head," as Arritt described his elaborate brushed and slipped blue cobalt and manganese floral trees, sprays, hearts, lines, squiggles, capacity designations, signatures, and initials, set his wares apart from those produced elsewhere in the valley during this period. Recognized forms include but are not limited to canning crocks (fig. 15), storage jars (figs. 16, 17), jugs (fig. 18), bowls (fig. 19), milk pans (fig. 20), cake crocks (fig. 21), pitchers (figs. 22, 23), churns of various sizes (figs. 24-26), miniatures, and tombstones. Family tradition holds that he was the first potter in the region to design the small-mouth crock with flaring rim and recessed interior rim/shelf that easily accommodates a wax seal (see fig. 15).[20]

The frequency of decoration on his wares is high. A conservative estimate is that 75 percent of his wares were either decorated, signed, or both decorated and signed. His frequently used elaborate brushed cobalt or manganese trees covering the majority of the front of the vessel's surface contained leaves and flowers often interpreted as representing hearts. Whether the hearts were intentional is unclear, but that the decoration most commonly used by Fulton is related specifically to the Germanic-influenced tree-of-life motif, best exemplified on the tombstone discussed previously (fig. 9), is unquestionable.

Many of Fulton's surviving wares and archaeologically recovered sherds illustrate problems he faced in controlling the variables (i.e., maintaining and controlling adequate firing temperatures, application of glaze, and monitoring kiln oxygen/reduction atmospheric conditions) necessary to produce quality stoneware. The frequency of draw trials recovered from test excavations speak to this problem and show Fulton's continuing attention and attempts to both monitor and adjust the variables necessary for a successful firing, which would ensure proper vessel vitrification, even glaze application, and contrast of decoration against the vessel body.

Arritt's comparison of Fulton's stone crocks with those produced by Waddell is probably in error in this descriptive account. Given Fulton's close though not well-documented association with Waddell prior to their arrival in Alleghany County, and the proximity of their stoneware kilns along Pott's Creek, it is much more likely that Arritt was referring to the redware production of Bodell's Pottery in the vicinity of Blacksburg, which is, unfortunately, even more poorly documented.

Also of particular interest is Arritt's statement that Fulton himself was responsible for decorating his wares. It is clear from comparisons of the signature on his crocks with those from surviving historical documents that the same hand was responsible for both. Variation in selected decorative motifs and the manner and detail with which they are executed is noted within the extant assemblage examined during this research, suggesting that someone else may have had a hand in decorating (fig. 27). With the exception of the cooler discussed previously (figs. 5-8), perhaps the most impressive of his decorated wares are those embellished with both cobalt and manganese decoration (fig. 28).[21]

Fulton's Final Move to Botetourt County and Retirement

Although family tradition states that Fulton moved to Botetourt County about 1875, he appears as a potter in the 1880 Alleghany County census, and, as mentioned previously, advertised himself as a potter located at "Arritts, Alleghany County" in an 1884 - 1885 Richmond newspaper.[22] The date ascribed to his move may relate to the assertion that he had established or was associated with a retail outlet for his pottery in Fincastle, Virginia, during this time.[23] A document indicating that Fulton assigned a judgment against a Joseph(?) for $62 with interest from June 1, 1879—plus $8.92 in court costs previously granted to him by the Botetourt Circuit Court on May 29, 1880—to a T. M. Allen is dated September 21, 1888, and bears a signature matching that which is so frequently seen on his wares: "George N. Fulton."[24] This would suggest that as early as 1879 and certainly no later than 1888 Fulton was residing in Botetourt, although it is clear that his ties there, both in terms of family and business associations, were well established before this time.

In fact, family tradition points to an 1876 birthdate of one of Fulton's daughters in Botetourt as evidence of his even earlier residence there.[25] The historical record, however, shows that three of his daughters, Mary, Elizabeth, and Amanda, were born in Alleghany County in 1874, 1878, and 1879, respectively. Whatever the case, that he eventually made the final move to Botetourt is incontrovertible, as both he and his wife are buried in the Noftzinger family cemetery near Fincastle, Virginia.[26]

While evidence of Fulton's pottery manufacturing in Botetourt County is limited, oral history is replete with wide-ranging theories relative to his late-nineteenth-century Fincastle-area activities. These include but are not limited to the following:

1. Fulton decorated wares produced in Botetourt with blue cobalt, whereas wares produced in Alleghany County were embellished with brown or manganese dioxide. (Sherds recovered from his Alleghany pottery exhibit both cobalt and manganese decoration. No cobalt-decorated wares produced by Fulton in Botetourt have been identified.)

2. The source for the clay Fulton used in the Fincastle area resulted in the vessels made there being of a brown or red color. (While the Fincastle/ Botetourt area is characterized by a strong emphasis on earthenware production, beginning in the late eighteenth century with Christian and continuing with Hinkle and Spigle, the Obenchains, and the Noftzingers into the 1880s, with their products being reddish brown in color and typically having a lead glaze, there are no known signed Fulton brown, red, or lead-glazed earthenware crocks known to have been made in Fincastle. There is, however, significant variation in the color of his wares, which relates to different sources of clay and problems in reaching and controlling proper firing temperatures for stoneware production. As a result, many of his wares may be referred to as redware and may be porous and exhibit a reddish color, but they typically will have a salt glaze, indicating his intended product was a vitreous stoneware.)

3. Fulton's potting activity in Botetourt was in association with the Noftzinger family. (It now appears that the Noftzingers' activity was limited to earthenware production with no signed vessels from their pottery having been identified. Given that the period of Fulton's residence in Botetourt was coincident with their period of operation, that their families were connected, that he and his wife are buried in the Noftzinger family cemetery, and the absence of any signed Fulton stoneware with a definite Botetourt provenance, it seems likely that any involvement Fulton had in pottery manufacturing in Botetourt concerned earthenware production in association with the Noftzingers.)

4. Fulton made and marketed his wares on Back Street in Fincastle.

5. Fulton's wares were sold at an outlet in Fincastle operated by the Lusters.[27]

That a local merchant owned or rented a building on Back Street where pottery wares were sold is well established, but Fulton's association with the shop or the marketing of his wares there remains unresolved. The well-documented history of Fincastle in the late eighteenth century identifies a pottery located along Back Street (more recently known as the Sally Douglas Home), that was operated by Israel Christian and situated across the street from his log residence (known more recently as the Becky Holmes House). An influential figure in Fincastle history, Christian had in 1770 offered some forty acres (from a larger land grant from King George III) for the establishment of a town to serve as the county seat for Botetourt. The site of the pottery operated by Christian during the late eighteenth century was purchased by the Lusters in 1878 and they were said to have offered pottery wares for sale there through 1885, while simultaneously operating a larger retail mercantile outlet on Roanoke Street.[28]

Recent examination of ceramics from local domestic sites in the Fincastle area has revealed some fascinating lead-glazed earthenware sherds with polychrome slip decoration, reflecting certain Germanic/Moravian influences, that perhaps are a product of Christian's pottery shop. Although the exact nature, extent, or duration of his activity is unknown, this is a promising area for future research. While it seems very unlikely that what once may have been an important late-eighteenth-century pottery concern remained in continuous operation for some ninety years until Fulton's involvement at retirement, it is likely that this late-eighteenth-century earthenware pottery shop of short-lived duration served, some one hundred or so years later, as an outlet for regionally produced stoneware by the Lusters, and may have included wares made by Fulton in Alleghany County or those produced by the Noftzingers, Obenchains, or others in Botetourt.[29] On the other hand, without sufficient documentary evidence, it may be that the identification of a house as the location of a pottery shop in the distant past (late eighteenth century) may have been inaccurately transposed to the more recent past (late nineteenth century) as representing, relating to, or attributed to Fulton's well-known regional pottery endeavors despite no solid documentary evidence of his involvement in pottery manufacture in Botetourt or of his pottery wares being sold at this location in the late nineteenth century.

Fulton Pottery: An Assessment

Fulton's thirty-eight-year participation in this evolving traditional craft industry and his successful establishment and continuing pottery operation in a relatively isolated rural Virginia setting for some eighteen years reflect, to a certain degree, his intimate understanding of his craft and a reliance on and strict adherence to its time-tested methods. Despite his familiarity with advancing industry technologies and shifting production methods, Fulton insightfully viewed the success of his enterprise in the context of understanding the local community's need. His utilitarian wares, embellished with a decorative aesthetic component, apparently were appreciated by consumers without a need for significant change or modification. Although he held fast to his traditional methods of production and marketing, it is obvious through an examination of both extant wares and archaeologically recovered sherds that there was some shifting in the variety and percentages of wares produced through time with some limited experimentation with more modern forms (fig. 29). These wares of "good stone body," delightfully decorated with "them fancy patterns out of his head" (fig. 30), reflect Fulton's enduring legacy as one of the Virginia highlands' most successful mid- to late-nineteenth-century traditional potters.

While the stage is set for understanding the success of his enterprise and the appeal of his wares to nineteenth-century consumers, the recent appreciation and collecting pursuit of his wares for the historic ceramic enthusiast of the twenty-first century must be viewed in the context of the enduring graphic appeal of these traditional handcrafted wares produced from the earth to fulfill a continuing utilitarian need while simultaneously reflecting the consumers' shared cultural aesthetic.

Gay Arritt, “Fulton Pottery,” in Gay Arritt, Historical Sketches, (Covington, Va.: Alleghany Historical Society, 1982); Kurt C. Russ, “The Traditional Pottery Manufacturing Industry in Virginia: Examples from Botetourt and Rockbridge Counties,” Rockbridge Historical Society Proceedings (Lexington, Va.) 10 (1990): 453–89; Kurt C. Russ, “Exploring Western Virginia Potteries,” Journal of Early Southern Decorative Arts 21, no. 2 (1996): 98–138; Kurt C. Russ, “Making Pottery in Botetourt County,” Journal of the Roanoke Historical Society 13, no. 2 (1996): 59–74.

Paul Mullins, “Historic Pottery Making in Rockingham County, Virginia” (paper presented at the Archaeological Society of Virginia Symposium, “Ceramics in Virginia 1988,” Virginia Piedmont Community College, Charlottesville); Paul R. Mullins, “Defining Boundaries of Change: The Records of an Industrializing Potter,” in Text Aided Archaeology, edited by Barbara J. Little (Boca Raton, Fla.: C.R.C. Press, 1992), pp. 179–93; Kurt C. Russ, “The Archaeology of Nineteenth-Century Virginia Coarsewares,” in The Transformation of Virginia from 1800 to 1900: An Archaeological Synthesis, edited by Ted Reinhart and John Sprinkle, Special Publication No. 31 of the Archaeological Society of Virginia (Richmond, Va.: Dietz Press, 1995).

Brenda Fulton Booker (bbooker955@aol.com), personal communication, 2003; Nancy Pruter (bobpruter@earthlink.net), personal communication, 2003.

Edward F. Witsell, Major General, Dept. of the Army, September 23, 1948, to Ms. Edna Cantrell, Covington, Virginia.

Virginia Fincastle Herald, June 23, 1938; interview with Edna Cantrell, granddaughter of Fulton, by Chris Donahue, Washington and Lee University, 1987.

Richmond Whig publication dated April 15, 1865; William C. Ketchum, The Pottery & Porcelain Collector’s Handbook (New York: Funk & Wagnalls, 1971), p. 191.

Virginia Fincastle Herald, June 23, 1938; Arritt, “Fulton Pottery”; interview with Edna Cantrell, 1987.

Wood County Marriage Record (West Virginia), no. 2, p. 35.

Alleghany County Deed Book 6, p. 444.

Alleghany County Census Records, Boiling Springs District, 1880; Alleghany County Deed Book 7, pp. 388, 554.

Virginia Department of Historic Resources, Richmond, Virginia, site files number 03-14 and 03-15. This is most likely the same site referred to by Mr. Arritt in his interview with Ms. Rawson as being the location where he collected the clay and transported it to Fulton’s shop for processing; Marion N. Rawson, Candleday Art (New York: E. P. Dutton, 1938), p. 104.

Virginia Gazetteer, 1884–1885.

Alleghany County Census Records, 1850, 1860, 1870.

August 15, 1857, land deed shows Waddell was apparently granted two-and-one-half shares in this ninety-eight-acre parcel adjoining J. D. Scott’s land and on which Jacob Wolfe had previously resided. Land Deeds for Alleghany County, Alleghany County Court House, Covington, Virginia.

Rawson, Candleday Art, p. 107.

Alleghany County Census Records (First District, July 20, 1850) list John Brown (49 years old) as being a potter born in Maryland and having a wife, Elizabeth (37 years old), five daughters, and three sons, two of whom—Gustavus A. (16 years old) and John W. (16 years old)—are listed as being born in Virginia circa 1834 and as being potters working with their father in Alleghany circa 1850

Rawson, Candleday Art, pp. 104–5.

Ibid., pp. 105–6.

Ibid., p. 106.

Interview with Edna Cantrell, 1987; Owen Barnes, “George Fulton Made Pottery in Potts Creek Area,” Covington Virginian, August 7, 1975.

See a similarly decorated five-gallon churn manufactured by Fulton in Russ, “Archaeology of Nineteenth-Century Virginia Coarsewares,” p. 109, fig. 2.

Virginia Gazetteer, 1884–1885.

Dorothy Sue Simmons Kessler, G. N. Fulton Pottery Booklet (Fincastle, Va.: Historic Fincastle, Inc., 1987). Unfortunately, no references are provided in this booklet relative to Fulton’s wares being marketed or sold on Back Street by the Lusters. In fact, the general lack of proper referencing throughout this brief consideration and the absence of citations make it impossible to know the source of the information or to whom it was originally attributed, in order to properly evaluate, investigate, and confirm or refute its accuracy. We must look to continuing thoughtful research and hope for the possibility of discovering ledgers from their (the Lusters and/or Fulton’s) operations, which would surely prove enlightening.

Botetourt County Court House, Fincastle, Virginia. One characteristic of Fulton’s signature is that the horizontal line meant to cross the “t” is typically found above the “o” and “n,” having missed its intersection with the vertical line intended to form a “t.”

Kessler, G. N. Fulton Pottery Booklet, pp. 7–8.

Fulton passed away in 1894 in Botetourt County and his wife died in 1910 in Roanoke, Virginia, but both are buried in the Noftzinger family cemetery located south of Fincastle along Route 220 to the northeast of its intersection with Route 640, adjacent to a residence formerly owned by a Commander Ware. The Noftzinger pottery kiln was located in the same vicinity just southwest on the intersection of Route 640 with Route 602; see Kurt C. Russ, “The Fincastle Pottery (44bo304): Salvage Excavations at a Nineteenth-Century Earthenware Kiln Located in Botetourt County, Virginia,” in Technical Report Series, no. 3 (Richmond, Va.: Department of Historic Resources, 1991); see also Virginia Fincastle Herald, June 23, 1938; Cantrell interview, 1987; and Russ, “Making Pottery in Botetourt County.”

Virginia Fincastle Herald, June 23, 1938; Arritt, “Fulton Pottery”; Cantrell interview, 1987; Kessler, G. N. Fulton Pottery Booklet.

Katherine C. Harris, “Fincastle Building,” in Historic Fincastle 1772 (Fincastle, Va.: Historic Fincastle, Inc., 1976), pp. 6–11. Also see Harold Eads, “Town of Fincastle,” in Historic Fincastle 1772, p. iv; and Kessler, G. N. Fulton Pottery Booklet, p. 9.

Russ, “Fincastle Pottery,” pp. 59–74; Russ, “Traditional Pottery Manufacturing Industry in Virginia.”