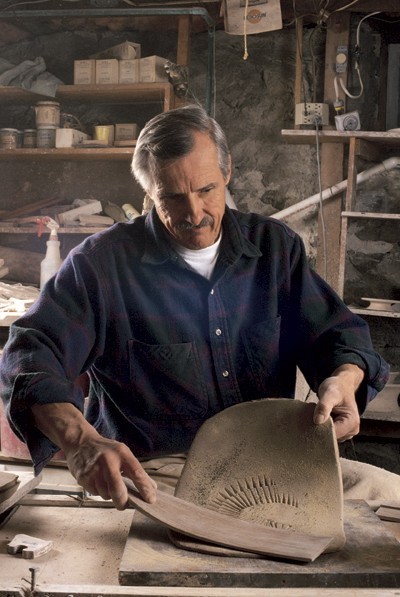

Richard Schalck at his basement workbench making “corrugated” slabs. Marblehead, Massachusetts, 2002. (Unless otherwise noted, all photography by Gavin Ashworth.)

Detail of signature on the base of a Schalck vessel.

A group of Schalck’s utilitarian production.

The dragon logo of Schalck’s Elm Street Pottery.

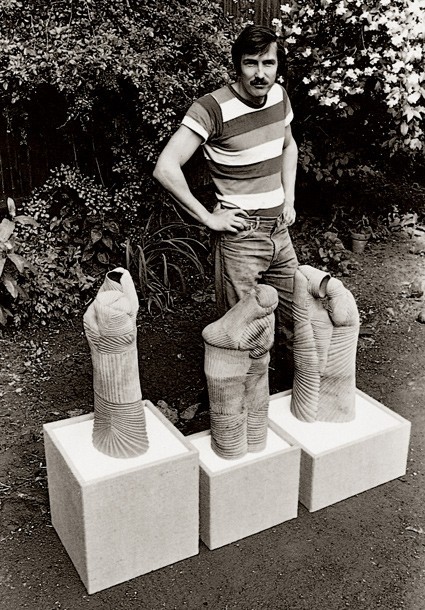

Richard Schalck, “Family of,” 1976. Unglazed stoneware. H. of tallest: 23 3/4".

The artist with “Family of” at the bicentennial arts festival at Abbot Hall, Marblehead, 1976. (Courtesy, Marblehead Reporter.)

Richard Schalck, vessel, 1979. Partially-glazed stoneware. H. 28 3/4".

Richard Schalck, vessel, 1980. Unglazed stoneware. H. 18 1/8".

Richard Schalck, vessel, 1980. Partially glazed stoneware. H. 22 1/2".

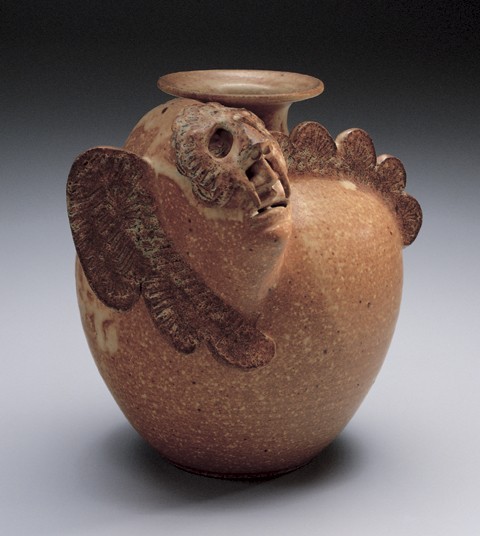

Richard Schalck, vessel, 1982. Unglazed stoneware. H. 15 1/4".

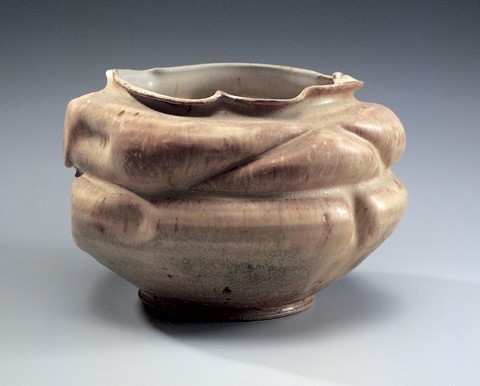

Richard Schalck, vessel, 1991. Glazed stoneware. H. 15".

Richard Schalck, vessel, 1993. Partially glazed stoneware. H. 17 5/8".

Richard Schalck, “The Jed Johnson Vase” (one of four), 1993. Stoneware with Albany slip. H. 24 5/8". (Private collection.)

Richard Schalck, “The Pier at Chicxulub Puerto,” 1993. Watercolor and ink on paper. 14" x 17".

Richard Schalck, “Fantasy Drawing,” Chicxulub, Puerto, 1992. Watercolor and ink on paper. 17" x 14".

Richard Schalck, “Dogs of Chicxulub,” 1995. Glazed stoneware. H. 3".

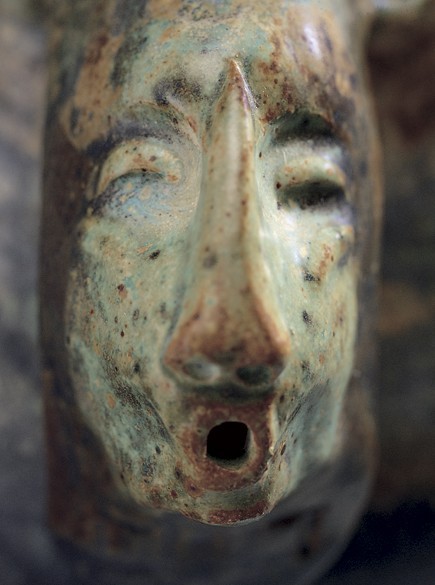

Details of the sculpture illustrated in fig. 16.

Details of the sculpture illustrated in fig. 16.

Details of the sculpture illustrated in fig. 16.

Richard Schalck, vessel, 1995. Glazed stoneware. H. 5 1/2".

Richard Schalck, vessel, 1995. Glazed stoneware. H. 7".

Richard Schalck, vessel, 1993. Glazed stoneware. H. 6 1/2".

Detail of the vessel illustrated in fig. 20.

Richard Schalck, vessel, 1995. Glazed stoneware. H. 3".

Richard Schalck, vessel, 1993. Glazed stoneware. H. 8 3/8". (Collection of Pamela Schalck.)

Detail of the vessel illustrated in fig. 23.

Richard Schalck, sculpture, 1993. Glazed stoneware. H. 7 1/4".

Richard Schalck, sculpture, 1994. Glazed stoneware. H. 10 1/2".

Detail of the sculpture illustrated in fig. 26.

Richard Schalck, vessel, 1992. Glazed stoneware. H. 3 7/8".

Top view of the vessel illustrated in fig. 28.

Richard Schalck, vessel, 1998. Glazed stoneware. H. 9 1/2".

Top view of a vessel by Richard Schalck, 1997. Glazed stoneware. W. 11 1/4".

Richard Schalck, vessel, 1995. Glazed stoneware. H. 5". (Collection of Chris and Merel Monaco.)

Richard Schalck, vessel, 1998. Glazed stoneware. H. 6 3/4".

Richard Schalck, sculpture, 2000. Glazed stoneware. H. 15".

Richard Schalck, sculpture, 1999. Glazed stoneware. H. 11 3/4".

Richard Schalck, sculpture, 2000. Glazed stoneware. H. 13 1/8".

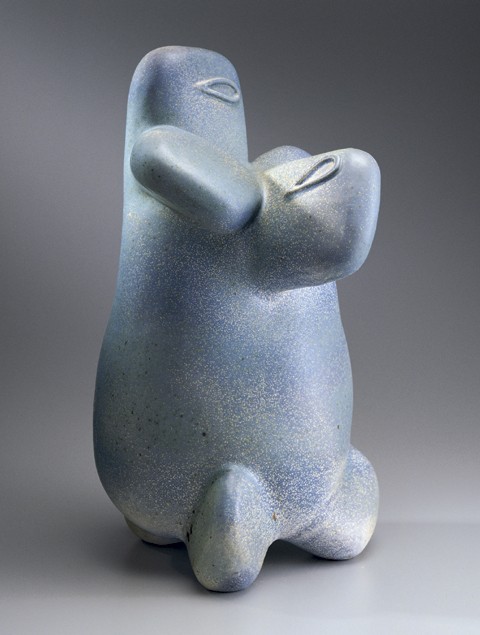

Richard Schalck, sculpture, 2001. Glazed stoneware. H. 21 1/4".

Richard Schalck, downspout, 1990. Glazed stoneware. H. 18". (Private collection.)

Richard Schalck.

Depicted increasingly in my sculptural ceramic forms in stoneware is my love affair with the country of Mexico. Annual journeys to the south of that country inspire both my clay pieces as well as the work of Pamela Schalck, my wife and traveling companion. Confronted with the diYculties of setting up to work in clay while there, I chose instead to work in two dimensions. I have tried to bring back something of how I feel about this land in my drawings, paintings, and prints. My warm connection to this part of America, its people and its cu1ture greatly influences my work. Each year I absorb great waves of inspiration from this enigmatic place, where the ancient and modern intertwine.

As an artist and as a human being, I feel also a strong connection to the natural world with its endless perfection, and my work exhibits a powerful pun towards the textures and colors of nature. Yet it is also the alteration of our natural world both positively and negatively by the human animal that is of profound interest to me as an artist. In Mexico, the kaleidoscope of contrasts inspires me to see the beauty and fullness of life more clearly.[1]

Running parallel to the well-publicized commerce of art potters who actively pursue gallery and museum sales and publish articles in magazines is the quiet world of the utilitarian potter. The utilitarian potter makes a living running a business, regularly firing small kiln-loads for domestic consumption, and only pursuing artistic production as a sideline. These individuals, who are often viewed with disdain by the more academic art potters, rarely gain artistic recognition.

Stoneware potter Richard Schalck has produced major vessels and slab-built sculptures for almost thirty years, but not a single work by him is in a major museum collection. His natural reticence and distrust of manifestos are one reason for his relative obscurity, but Schalck also seems to feel that participation in gallery shows and marketing to museums gets in the way of his conceptualization and execution. His production of strong, functioning utilitarian pots is important to him, but he has not had an interest in industrial design, as such. He even shies away from giving his sculptural works titles even when they have strong associational motifs.

This article gives an overview of some representative examples of Schalck’s individualistic work, but it by no means captures the full range of his nuanced and elusive nature. Schalck was born in 1940 in Morristown, New Jersey. In 1948, his family moved to East Boston. Schalck attended Dorchester High School (which had a progressive arts program by 1950s standards) and then Lynn English High School. He studied at Massachusetts College of Art at the old Brookline Avenue campus from 1958 to 1962. While he took the regular MCA survey courses, including painting, drawing, and architecture, Schalck began to concentrate on ceramics in his sophomore year.

Three professors especially influenced Schalck’s development. Charles E. Abbott was a superb technician in the Arts and Crafts tradition who stressed command of the medium, including bodies, glaze formulae, and firing temperatures. Russell Doucette was a strong mechanical engineer but also emphasized the history and beauty of Meso-American and Asian art, both of which have been fundamental to Schalck’s work. Bill Wyman was a more expressionistic teacher who later achieved national recognition. He is remembered today for his self-portrait heads and temples in many museum collections. Wyman was a friend and colleague of Peter Voulkos, the California abstract expressionist potter who revived the rough, expressionistic style of the Mississippi Arts and Crafts potter George Ohr.

After graduation, Schalck worked as a union carpenter from 1963 to 1973. In that year he finally built a kiln in the carriage house of his wife’s parent’s house at 148 Elm Street in Marblehead. His first kilns were simple downdraft examples with arched chambers built of soft and fire brick and fired by gas. Schalck has always concentrated on stoneware, although he has made a certain amount of terra cotta. At school he had learned to make ceramics in electric-fired kilns that only reached cone 5 (approximately 2200 °F). Since true stoneware clays require higher temperatures, with his earliest experiments in making stoneware, Schalck had to resort to fluxing stoneware clays to melt at lower temperatures. Once he built his own gas-fired kiln, he began firing at higher temperatures.

The results of that first firing were uneven, but the strong technical background Schalck had received at MCA prompted him to overcome problems. He has rebuilt his kiln six times since 1973 as the rigors of high temperature firing have taken their toll. The last time he supplemented his own experience by bringing in a consultant who provided expertise on the relative sizes of the chamber and the flue, the position of the damper and burner, and insulation of the floor and roof.

Schalck has pursued a living making utilitarian pottery. Like many potters, he promoted his business locally at art fairs and shows or by demonstrating at festivals or in schools. He occasionally placed ads in the local newspaper, The Marblehead Reporter.[2] His initial forays into making what he refers to as “sculpture” was a 1975 castle, where he experimented with rough surface textures he calls “corrugations.”

To create these sculptures, Schalck cuts slabs with a simple guitar-string arrangement. He then begins altering the slabs by working in grout and making corrugations with a tile or a wooden implement like a clothespin. The resultant patterns and relief are suggestive of fossilized trackways or patterns made by wave action, but their coarse texture gives them a strong sculptural quality, as though they were carved rather than incised. In 1976 Schalck created a composition of three slab-built groupings of creatures which he called “Family of,” a rare exception to his use of titles for his works. These sculptures were first of what was an entire series stretching over twenty years.

The heavily-grogged stoneware clay Schalck uses, generally a brownish buff color, is usually sparingly glazed (if at all) in pale, mat glazes inspired by Song Dynasty wares. However, Schalck had little appreciation early in his career for vases in “antique” Asian-styles. Only later would he accept such forms as commissions for what he saw as a technical challenge, building them out of six or seven components.

His earliest work was hampered by the problems of stoneware construction and firing, including shrinkage, cracking, dunting, warping, and slumping. Schalck has used a variety of clay sources, although he notes that the number of supply houses has dwindled in recent years. Most of the stoneware clays he presently uses are from southern Appalachia. Schalck’s usual stoneware body is mixed with grog in the form of pre-fired ground stoneware particles to which he has added other clays for color, but he usually sticks with a buff color. He uses a Bluebird pug mill (a motor-driven screw in a tube) to blend in both light- and dark-colored grog for color and texture. He then wedges the clay by hand on a board. In throwing vessels, Schalck uses both a kick wheel and a motor-driven Shimpo wheel with a variable speed pedal.

Most wares are fired in a gas-fired kiln twice, first a biscuit firing at cone 6 (1800°F) and second a glaze firing at cone 9–10 (2235 to 2381°F). Schalck has used a variety of slips made of locally dug clay or of pipe clay, which is porcellanous, but usually he employs only glazes. These are about 50–60% feldspar, but also include limestone, whiting, alumina, and white kaolin. Fluxes are borax, zinc, and barium. Colorants include iron, copper, cobalt, nickel, and occasionally wood ash. However, Schalck does not consider himself a glaze technician. He has ball-milled some pigments like Albany slip but prefers rougher grades of materials in their natural state.

Since 1988, Schalck and his wife Pamela have made annual trips to Mexico and have visited every Mexican state. He has funded these research trips by offxering works by himself and his wife in return for subscriptions. In part, his choice of destinations was influenced by his teacher Russell Doucette, who emphasized the artistic achievements of the Olmec, Maya, and Aztec. Although Schalck has visited some traditional potters in Mexico, he concentrates on archeological sites and museums.

Although he recognizes the importance of artistic wares like those produced by Gorky Gonzales, they do not fundamentally interest him.[3] A definite artistic influence, however, was the landscape of the American Southwest, particularly desert mesas. To some extent the eroded slopes reinforced the motif of corrugated surfaces on some Schalck sculptures; several have steps or doorways that might be oblique references to pueblos.

Some direct Mexican motifs are seen in a series of fin pots and others that reflect feathers, fruits, and vegetables. In a few instances, Schalck has made sculptures incorporating tiny figures that quote Meso-American carvings. However, these rare break-outs of overt influence are far more common in the concept and landscape drawings that Schalck has executed on his trips. Several more recent sculptures are made of thinner slabs but are worked into bulbous, ambiguous forms that are puzzling and sometimes a bit threatening. These smoother forms with complex sprayed glazing represent a genuine formal departure, as well as a new psychological threshold for the artist.

It is difficult to predict what directions Schalck’s production might take as the artist heads toward retirement from commercial production. The glare of public recognition attendant to articles like this might have any number of consequences for a practicing potter who has avoided it. However, one anticipates that Schalck might concentrate more and more on sculptures, perhaps moving into an overt Meso-American phase. The confrontation of his quiet personality with some of the extreme sacrificial aspects of historic Meso-American civilizations is tempered by his genuine regard for modern Mexicans. The only odd aspect of this is Schalck’s apparent lack of a taste for incorporating the colors of the Mexican palette, another avenue he might explore in a mannered future phase.

Statement by Richard Schalck, May 1993, Abbot Public Library, Marblehead, Massachusetts.

Published newspaper accounts of Richard Schalck’s works include Boston Globe, North Shore Supplement, September 2, 1987, p. 17b; Boston Globe, North Shore Supplement, July 10, 1983, pp. 16–17; Salem Evening News, September 29, 1987, pp. 1 and 9; Salem Evening News, January 4, 1995, p. 9; Marblehead Reporter, March 18, 1982, p. 15; Marblehead Reporter, June 22, 1977, pp. 19, 24.

See http://www.gorkypottery.com/