The wood-firing pottery kiln of Greg Shooner and Mary Spellmire-Shooner, Oregonia, Ohio, December 3, 2015. (Photo, Brenda Hornsby Heindl.)

Greg Shooner stoking the firebox of his wood-firing kiln, December 3, 2015. (Photo, Rob Manko.)

Jar, Greg Shooner, Oregonia, Ohio, 2015. Lead-glazed earthenware. H. 7 1/2". (Photo, Rob Manko.)

A collection of pottery made by Greg Shooner in front of the firebox of his wood-firing kiln, December 3, 2015. (Photo, Rob Manko.)

Dish, attributed to Henry Troxel, Upper Hanover Township, Montgomery County, Pennsylvania, 1828. Lead-glazed earthenware. D. 10 1/4". (Courtesy, Philadelphia Museum of Art.)

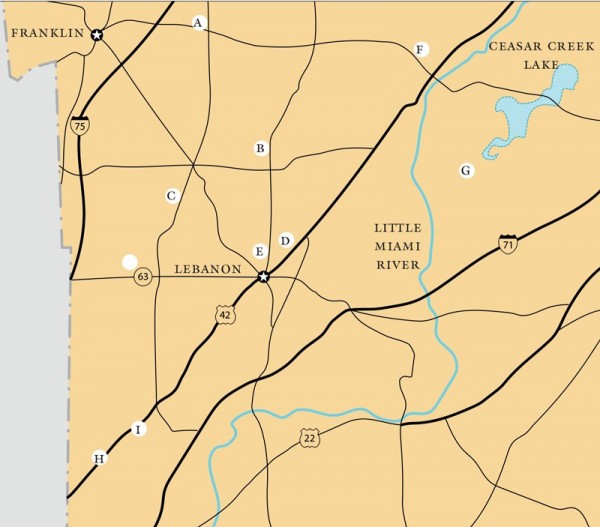

Map showing the location of potters working in Warren County, Ohio, in the nineteenth century.

A. Joseph Walters, 1840–1860

B. Merritt/Gray, 1810–1860

C. Shaker, 1860–1851

D. Wm. Jackson,Wm. Shugert,

John Foglesong, 1835–1884

E. George Foglesong, 1810–1831

F. Thomas Swift, 1808–1836

G. Elisha Vance, 1828

H. Silas Ballard 1859–1879

I. Wm. Jared, 1848–1883

Jar, attributed to Stephen Easton, Union Village Shaker community, Warren County, Ohio, 1827. Lead-glazed earthenware. Mark (incised on base): August / the 17, 1827 / Stephen (Photo, Greg Shooner.)

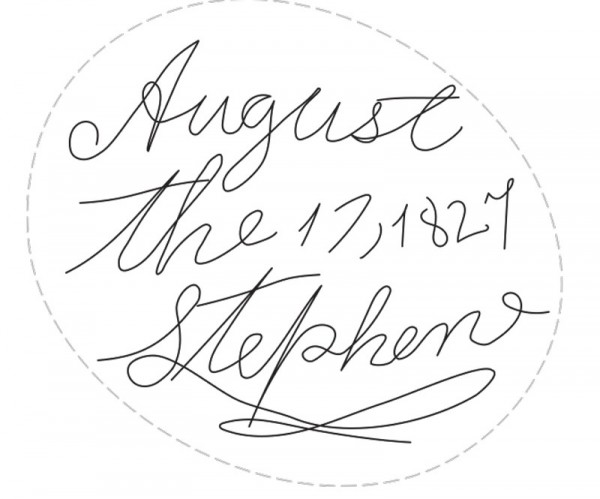

Illustration of the inscription on the base of the jar illustrated in fig. 7.

Aerial view of excavation on the North Family Lot, Union Village Shaker community, Warren County, Ohio, 2005. (Courtesy, Ohio Department of Transportation.)

Nineteenth-century pipe heads excavated at the North Family Lot, Union Village Shaker community, Warren County, Ohio, 1804–1852. (Courtesy, Ohio Department of Transportation.)

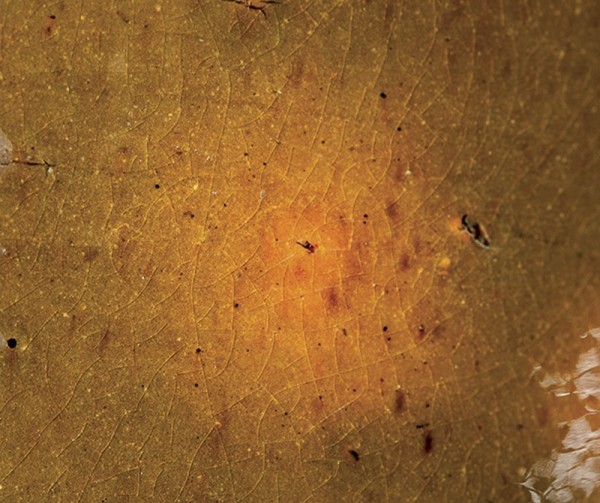

Raw clay before it is processed in the pug mill. (Photo, Greg Shooner.)

Raw clay before it is put into the pug mill, showing the distinct color variations that will blend in the pug mill. (Photo, Greg Shooner.)

Dish, Mary Spellmire-Shooner, Oregonia, Ohio, 2015. Lead-glazed earthenware with slip-painted decoration. D. 8". (Photo, Rob Manko.)

Detail of the slip-painted decoration on the dish illustrated in fig. 13.

Jar, Greg Shooner, Oregonia, Ohio, 2015. Lead-glazed earthenware. H. 6". (Photo, Rob Manko.) Note that the white slip-trailing under the lead glaze, made using an iron-rich clay, gives the white slip a yellow appearance.

Jug, Greg Shooner, Oregonia, Ohio, 2015. Lead-glazed earthenware. H. 8". (Photo, Rob Manko.)

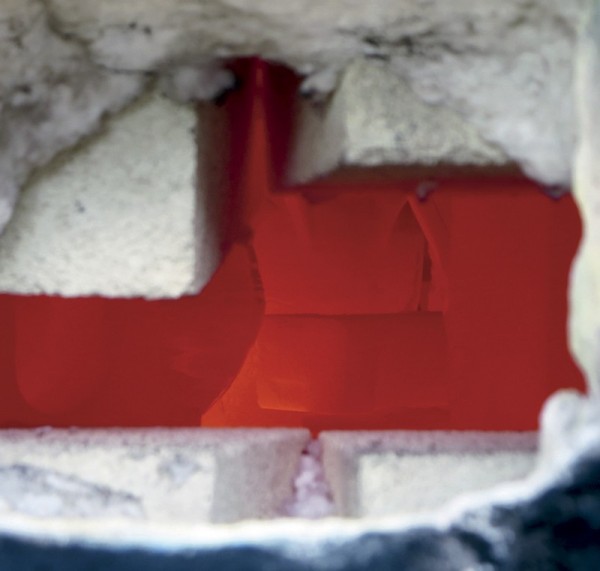

Firebox for the Shooners’ wood-firing kiln showing the deep red color that appears during reduction. (Photo, Brenda Hornsby Heindl.)

Flames coming through the ceiling of the wood-firing kiln and black smoke showing signs of reduction. (Photo, Brenda Hornsby Heindl.)

Showing the bright interior of the kiln and the visible sheen as the glaze fluxes during reduction. (Photo, Brenda Hornsby Heindl.)

Jar, New Market, Shenandoah Valley, Virginia, 1860–1880. Lead‑glazed earthenware. H. 7 1/2". (Courtesy, Jeffrey S. Evans & Associates Auctions, June 17, 2017, sale lot #1016; photo, Will McGuffin.)

Close-up of the jar illustrated in fig. 20, showing several places where organic material had burned out and left a small hole for oxygen to create a halo.

Jar, attributed to Galena, Illinois, 1860–1880. Lead-glazed earthenware. H. 8 5/8". (Courtesy, Jeffrey S. Evans & Associates Auctions; photo, Will McGuffin.)

Close-up of the base of the jar illustrated in fig. 22. Leaving the base unglazed allowed the glaze to oxidize around the base of exposed clay, creating a ring of yellow-orange color.

Jar, Greg Shooner, Oregonia, Ohio, 2015. Lead-glazed earthenware. H. 10". (Photo, Rob Manko.)

Close-up of one of Greg Shooner’s pieces on which a halo has formed. Note the pinhead hole at the center where the oxygen entered beneath the glazed surface. (Photo, Rob Manko.)

Left to right: Mary-Spellmire Shooner, Dorothy Auman, and Walter Auman, Seagrove, North Carolina, ca. 1986. (Photo, Greg Shooner.)

Pottery stacked in the Shooner kiln, ready for firing, December 3, 2015. (Photo, Brenda Hornsby Heindl.)

Extruded rail-style kiln furniture from the pottery site of Jacob Meddinger, Montgomery County, Pennsylvania, ca. 1920. (Private collection; photo, Rob Manko.)

Dish resting on rail-style kiln furniture. (Photo, Rob Manko.)

Dishes with coggled rims sitting on rail-style kiln furniture leaning against one another prior to firing. (Photo, Greg Shooner.)

Back edge of dishes that were leaning against one another during firing; the small marks show where the coggled edge made contact with another piece. (Photo, Greg Shooner.)

Coggling the edge of a dish. (Photo, Greg Shooner.)

Dish, Henry Roudebusch, Upper Hanover Township, Montgomery County, Pennsylvania, 1816. Lead‑glazed earthenware. D. 11 7/8". (Courtesy, Philadelphia Museum of Art.) The downward flow of the green copper oxides indicates that the dish was standing upright in the kiln during firing.

Pottery unloaded after the 2015 lead-glazed wood-fired kiln firing in the Shooner pottery shop. (Photo, Brenda Hornsby Heindl.)