Mark Shapiro at his traditional treadle wheel with a six-and-a-half-pound ball of clay. (Unless otherwise noted, all photos by Eli Liebman.)

Jar, Thomas Commeraw, New York, New York, ca. 1810. Salt-glazed stoneware. H. 12". (Private collection; photo courtesy Brandt Zipp, The Thomas Commeraw Project.)

Reverse of the jar illustrated in figure 2.

Detail of the handle on the jar illustrated in figure 2.

Detail of 19th-century Potter’s Society ribbon. (Courtesy, New-York Historical Society.) The printing die used to make this image of the wheel on that ribbon was in the possession of the Crolius family.

Centering the clay.

Opening the clay ball.

Raising the walls.

Smoothing and shaping the walls with the flat side of a wooden rib.

Profiling the foot detail with a rib.

Profiling the transition between the body and neck. The half-round carved-out cross section of the rib was used to make the bead.

The finished jar is cut off the wheel head with a twisted wire.

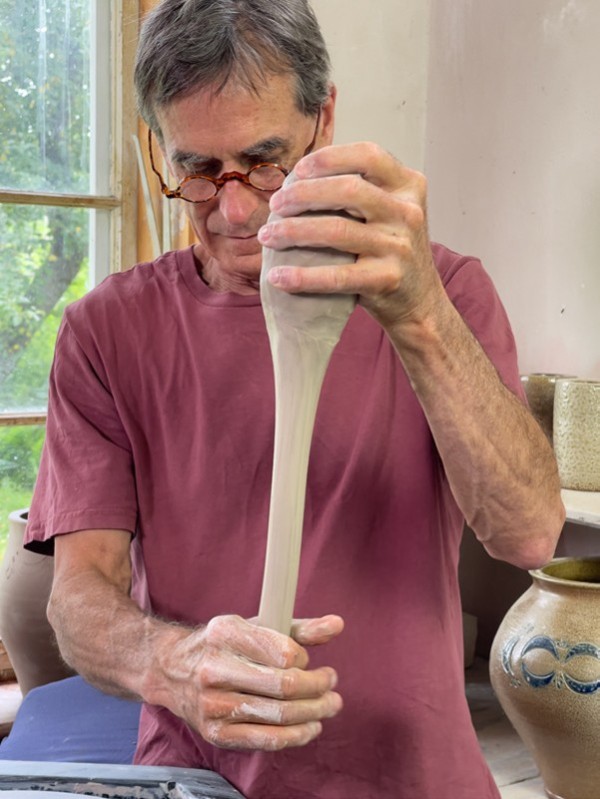

Pulling a round cross section of clay to make the free-standing handles. (Historically, this could have been done by extruding clay contained in a rectangular box through a wooden die with a plunger.)

Equal lengths for symmetrical handles are cut and reserved.

Ends of handle are thickened by tapping with a finger.

The placement points of handle attachments on the pot are marked in slip (fine wet clay).

Slip is scored to provide a solid connection between parts.

One side of a handle is attached to the pot.

Second side of the handle is attached.

Second handle has been attached, and one side is worked upward toward the neck to form a period free-standing handle.

Second side is worked upward.

A small coil of clay is added as a backfill to thicken the attachment.

Backfill clay is smoothed in.

Stamping the lune part of the swag-and-tassel motif.

Stamping the tassels.

Stamping a bowknot on reverse.

Lunes, showing broken line on upper arcs. (Collection of the author.)

Stamps fabricated from bent and soldered copper and brass strips.

Mounted typography stamps.

Morgantown stamp in a chase. (Courtesy, Collection of the Smithsonian Museum of American History.)

Stamping typography.

Filling stamped motifs with cobalt. The cobalt here is in carbonate form; it fires to a strong blue.

Painting handle attachments.

Wadded bisque-fired jar. While the original went into the salt kiln in the green state and would have been heated slowly through the initial stages of the firing to prevent cracking and explosions, I did a preliminary firing to enable faster gaining of early heat. Note that the previously pink cobalt carbonate is now blue.

Jar loaded in the kiln. My kiln is a downdraft catenary arch with two fireboxes on the sides. Commeraw’s kiln was probably an updraft, with multiple roof openings and the firebox underneath the floor.

Finished jar.